Punching shear and bonded reinforcement system

Flat slabs and/or element floors (precast slabs with in-situ structural concrete topping) as used in industrial and commercial buildings are state-of-the-art and allow great freedom in plan design. Design without loadbearing walls considerably reduces the cost of formwork and reinforcement and ensures barrier-free finishing and completion to full story height. Important is here to ensure that flat reinforced-concrete slabs, such as element floors or mushroom slabs that are point-supported on or point-loaded by columns have sufficient bearing capacity. In engineering, shear failure of a slab supported in the described manner is generally referred to as “punching shear.” Appropriate verification for checking punching failure must therefore be considered in the structural design.

Where a floor cannot absorb the calculated shear forces from a concentrated load alone with the loadbearing capacity of the concrete, the loadbearing capacity of the floor must be increased and ensured at the columns by additional punching shear reinforcement.

Approved by the building authorities

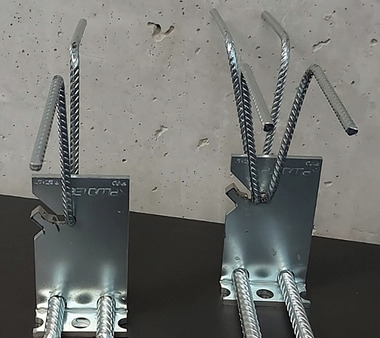

Clixs from Betomax systems is a new punching shear and bonded reinforcement system for use in precast floor elements. The Clixs system consists of punched and folded special steel plates provided with one or two additional stirrups of B 500 A/B reinforcing steel. To ensure positional stability and for anchoring the plates during installation, two B 500 B reinforcing bars of 12 mm diameter are guided through the predrilled holes in the plates.

The design software available as download is based on Eurocode 2 (EC 2) with the so-called nationally determined parameters (NAD) and takes into account national approval Z-15.1-281. The design program is specifically adapted to precast floor elements and includes all production specifications regarding the number, geometry and position of the Clixs line elements. In addition, the software performs the analyses for punching shear and bond.

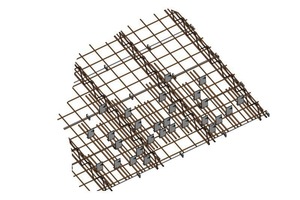

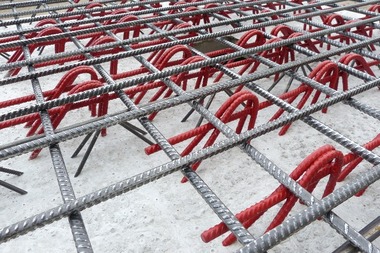

The line elements are assembled by sliding the L-plates onto the two reinforcing bars in accordance with the parts list. The elements are then systematically installed parallel to the directions of reinforcement in accordance with the design specifications. Due to the parallel arrangement of the elements, the confusion caused by conventional star-shaped laying of punching shear elements does not occur.

Clixs ensures in this way not only clear procedures during laying, but provides for more cost-efficiency in fabricating punching shear reinforcement for precast floors. The Clixs system, it goes without saying is approved by the German Institute for Construction Engineering (DiBT) in Berlin.

Individual solutions ex plant

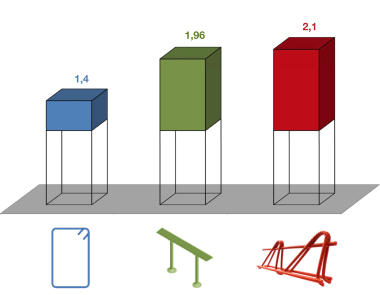

The key advantages of Clixs are already evident in the production process. The integrated Clixs plates enable precasters a low drive-over height and with that interference-free concrete discharge. This precludes any jamming or shifting during the automatic roughening process and, what’s more, the curing chambers in the precast plant can be optimally used. The Clixs plates are positioned below the lattice girders, resulting in the described reduction in the overall height of the precast elements. This advantage is especially important since in this way the subsequent stacking procedure for storage is not interfered with. The precast element floors, moreover, need not be supported by woods during transport so that more elements can be transported for every delivery.

To complete the installation phase, only the stirrups are clipped into the precast elements at the site in order to expertly connect the upper and lower reinforcement zones. For this it is not necessary to fit the stirrups perpendicular, but they may be installed at an angel of </= 30o. Special mention should be made of the fact that there is only one type of plate – precluding any confusion of different heights. The manufacturer not only supplies individual elements, but, in addition, customized individual solutions ex plant.