Reducing edge distances for composite sandwich anchor systems

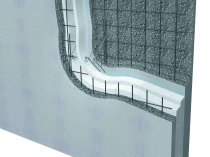

Philipp redefines long-standing limitations in terms of connecting layers of reinforced-concrete sandwich elements. The updated national approval (Z-21.8.2013) for the sleeve anchor and/or flat anchor (SA/FA) connection systems to some extent have reduced edge distances and center-to-center distances so far existing considerably. At present, for these systems this plus in flexibility for an application is without alternative, for the time being, and provides the planner with more possibilities compliant to the approval than ever.

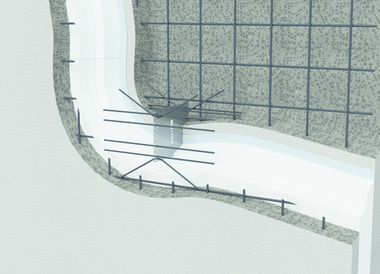

Mounting parts based on stainless steel such as sleeve anchors and flat anchors used for the connection of the two reinforced-concrete layers of precast sandwich walls have been the most widely used solution for many years without controversy. Whether regulated by a type-tested structural analysis in the beginning or by a national technical approval in the past few years, both systems define a recognized state-of-the-art method. A wide range of applications for usual sandwich elements is covered perfectly as mounting parts are available in a lot of sizes. No matter whether slim base plate or large-sized wall element are concerned, an anchoring solution can be offered from one of the two system alternatives for almost any case.

However, it becomes more and more difficult to meet the requirements stipulated by the approval, in particular, regarding the edge distance and center-to-center distance of the mounting parts. Due to increasing demands on shape, size and weight of the sandwich elements, planners as well as manufacturers of these mounting parts are faced with ever new challenges.

Anchoring surfaces reduced by more than 50 %

For many years, a uniform edge distance of 30 cm in all directions has been defined for both sleeve anchors and flat anchors, independent of the dimensions of the actual mounting part. This represents a significant disadvantage difficult to argue against, in particular, for small mounting parts. All edge and center-to-center distances, as well as rectangular, however, above all in parallel to the longitudinal axis of the mounting part were revised in the current national approval and adapted to the different sizes of the mounting parts. In this way, the required anchoring surface could be reduced by up to 57 % for flat anchors and by up to 51 % for sleeve anchors.

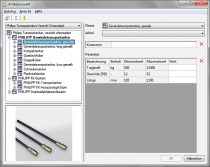

These new possibilities provide the planners and the manufacturing precast plants with a larger potential. However, they can hardly expect even more flexibility in the near future. Of course, this new feature has been integrated in the new version of the Philipp design software. This version, expanded by further useful functions, is available for download on the Philipp website (//www.philipp-gruppe.de" target="_blank" >www.philipp-gruppe.de:www.philipp-gruppe.de).