Romey expands Plaidt precast plant supported by Progress

Established in 1950 as a masonry block and hollow core slab producer with ten employees in Plaidt, Romey Baustoffwerke has evolved to become a well-known industry player currently employing about 240 people. The company continues to invest in its future and repeatedly decided, within only a few years, to purchase automated reinforcement systems from Progress.

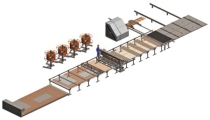

The investments will increase the degree of automation at the Plaidt plant, which includes three carousel lines supplied by Progress. The first two lines were extended in quick succession with MSR cross-wire straightening and cutting machines followed by VGA Versa lattice girder welding machines. A Wire Center will be added to the third carousel line in 2021.

Flexible, automated reinforcement systems

Within a short period, the long-established company invested in two MSR straightening and cutting machines and two VGA Versa lattice girder welding machines. The first machine, an MSR multirotor straightening and cutting machine with automatic spacer supply and automatic wire diameter changeover, was purchased in 2018. It works directly from the coil and convinced Romey to purchase a second of its kind shortly thereafter. In addition to the straightening and cutting machines, two six-fold EPT laying grippers were installed, each of which takes six bar spacers from the supply magazine and places them on the pallet fully automatically according to CAD-CAM specifications. The new machines for producing the reinforcement required for the precast floor slabs were customized to Romey’s specific needs.

Lattice girder welding machine with acoustic enclosure

Flexibility was also the key for the VGA Versa lattice girder welding machines, which were additionally fitted with an acoustic enclosure. Romey attaches great importance to pallet utilization, which also means that the pallets sometimes include three or four different lattice girder heights. In this setting, it is crucial that the girder height be changed quickly and automatically during the production process. The VGA Versa is the best choice in this regard because it is the only machine on the market capable of adjusting the height fully automatically within only a few seconds while at the same time welding the five wires of a lattice girder together in a continuous resistance spot welding process. This results in higher productivity and meets the objective of the new investment in the plant. The compelling performance of the first machine prompted Romey to purchase a second machine shortly thereafter. In fall 2021, a Wire Center for double wall production will be installed in order to provide additional reinforcement automation. The Wire Center lays the reinforcement according to CAD specifications, which results in an optimized process that increases production output and dimensional accuracy.

Precast elements for small-scale projects

The fully automated precast element carousel lines primarily produce precast floor slabs for smaller projects. Accordingly, Romey mainly supplies single- and multi-family house projects in Germany and Luxembourg, as well as in France. The three pallet circulation systems operated at the premises produce up to approximately 5,000 m² of floor slabs and up to 1,000 m² of double wall elements per day. The newly installed reinforcement systems provide additional support for adhering to the tight cycle times.

Managing Director Reinhard Vogt comments, “We were afraid that the new machines would not be able to keep up with about eight pallets per hour, but they manage to do so without any failure or breakdown. We haven’t lost a day due to technical problems in over a year.”

Flexible service

Keeping production downtime caused by assembly to a minimum was imperative for Vogt. Progress supplied large assemblies; the company tests and assembles small-scale electronics at its own plant beforehand. This arrangement saves a lot of time during assembly – after all, it is impossible to catch up in terms of output after periods of downtime, which is commercially unviable for producers.

“Progress does not shy away from challenges such as complex installation conditions or installation during ongoing production, as was the case with our MSR machines,” explains Vogt and adds, “We started work earlier and Progress started assembly later and assembled half the night. We then agreed on a similar arrangement for installing the VGA Versa machines. It is quite unusual to get this level of commitment, so Progress does stand out from its competitors in this regard.”

Progress through trust and quality

The managing director stresses that such an investment is not just about good machines, but much rather about the people with whom you do business. This requires mutual trust, which, according to him, is definitely part of his dealings with Progress representatives. Vogt adds, “In addition to the existing trust, the in-house programming and service departments are an invaluable asset. If something didn’t work, no matter what it was, it took only a few hours to get everything fixed again. This is what ultimately influenced our investment decisions, including in favor of the Wire Center in 2021.”