Shooting instead of welding

Ceilings which are built using a composite steel construction, benefit from the advantages of reinforced concrete and steel. Due to a nonpositive connection of both materials, they act as if they were one structural element. Therefore, in comparison with normal concrete constructions, they have a better fire resistance, a better airborne sound insulation and carry less dead weight. The attachment is often made with head bolts or other steel elements. Those are usually welded onto the steel girder, which is associated with enormous effort. It requires specially trained staff, and the site must be provided with electricity. That is not only time consuming, but also potentially dangerous. The Elascon company wants to offer an alternative.

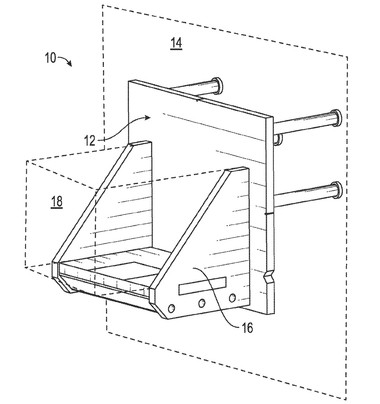

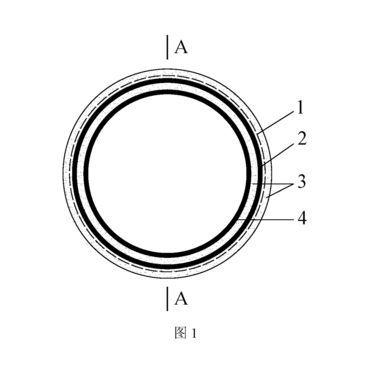

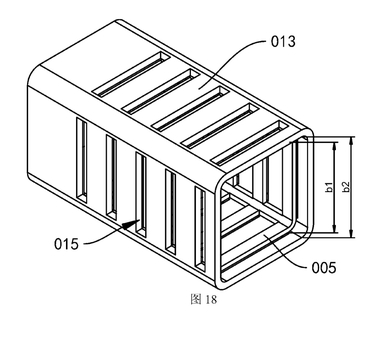

The manufacturer promises an easy attachment of the Spit-nails and the steel, due to their shear connectors Stabeko TFuse and Stabeko VFuse. The TFuse connector consists of a 12 mm thick head bolt, which is available in eleven different lengths. Two spit nails are necessary for the attachment with the steel girder. The shear connector shows a tensile strength of 2.300°N/mm2. The difference between the TFuse and the VFuse is the shape. The V-shaped connector require two to four spit nails, for the attachment. Both connectors received a building approval as well as an ETA approval. The possibility of tacking the shear connector to the steal has many advantages. There is no more welding fume rising, the assembly is not disturbed by the steel’s surface coating and the installation I independent of the weather. The manufacturer offers a software for an efficient dimensioning of the connectors.