Silhouette International: Modern eyewear optics cast in concrete

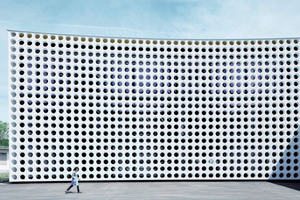

A white concrete façade with a multitude of circular window openings arranged in rows – this special feature characterizes the new production and storage facility of Austrian eyewear manufacturer Silhouette. With this project, X Architekten, a firm of architects based in Linz, and precast producer Systembau Eder from Peuerbach have succeeded in creating a true eye-catcher.

A white concrete façade with a multitude of circular window openings arranged in rows – this special feature characterizes the new production and storage facility of Austrian eyewear manufacturer Silhouette. With this project, X Architekten, a firm of architects based in Linz, and precast producer Systembau Eder from Peuerbach have succeeded in creating a true eye-catcher.

What do attractive eyewear design and modern cast stone have in common? Well – quite a lot when taking a closer look at the new building of Linz-based eyewear manufacturer Silhouette! For the goal of the architects was to use the exterior design of the building to create a link to the eyewear and in particular the lenses to be manufactured inside upon completion, while at the same time emphasizing the high quality standards placed on the products by both the client and its customers. The round openings are intended to reflect the reference to eyewear manufacture, whilst the design of the precast elements mirrors the lightness of design that is typical of the Silhouette frames.

In focus: the link between architecture and product

Silhouette International Schmied AG is an Austrian family business. Since the company was established in 1964, eyewear of an unmistakable, high-quality design has been produced at the headquarters in Linz under the Silhouette brand name. This long-standing tradition is based on both continuous development and a stringent corporate philosophy. On its homepage, Silhouette states that “the road was long from the first visual aid to an accessory of the greatest technological and design perfection.” According to the company, customers can today “choose between the delicate, almost invisible film of rimless eyewear or a spectacular fashion statement, between respectability, fun or illusion.” It goes on to state that “every person’s style is unique. Our eyewear is designed to refine and underscore an individual’s style. We are passionate about creating innovative, attractive designs for exceptionally lightweight, high-quality eyewear, which has put its own distinct mark on contemporary style.”

To continue the entrepreneurial spirit and take account of the potential for development, the decision was made in 2015 to expand the company’s production facilities. The task at hand was to add a central building with a usable floor space of approx. 2,500 m² to the existing company site with its heterogeneous building development of most diverse uses. To keep the distance to the existing workshops and offices as short as possible, an area housing an old single-storied building in the middle of the company premises was chosen as the location for the new building. Linz-based X Architekten was commissioned with the design. The name represents a group of dedicated architects who, according to their own understanding, “develop conceptual positions on contemporary architecture in project-related work.”

Small openings – big effect

According to the designers’ statement on their homepage, the “link between architecture and product was the driving force in the design process” of the Silhouette building project. The design by X Architekten therefore seeks to “combine two essential keywords of the company’s philosophy – lightness and strength – in built form while at the same time creating a contemporary and timeless design.” X Architekten go on to state that “the convex/concave shape of the lens is the central theme. A plain white ‘box’ is clipped on the south side by means of a convex line, leading to the entrance of the new volume through the resulting arch. The entrance is located in a shadow gap between the new and old buildings. The exterior look is created by smooth white precast concrete elements on all sides, with the ‘clipped’ south side being perforated in a grid pattern formed by hundreds of conical funnels. As a counterpart, the north side is given large, circular openings and windows with convex glazing. The overall design of the façade was developed under the aspect of achieving technical and creative perfection. As a result, a new dynamic link is again created with regard to the Silhouette product.”

High requirements placed on the precast producer

The design was realized by means of a smooth-formed façade of precast concrete elements produced by Systembau Eder based in the Austrian town of Peuerbach. The company operates state-of-the-art design and manufacturing technology in combination with high-quality formwork production.

The façade structure of the Silhouette building consists initially of a 30-cm thick in-situ concrete wall forming the shell. This is followed by a polystyrene insulation or mineral wool insulation, respectively, where specified by fire protection requirements. The façade is completed by 12-cm thick precast façade panels produced on the basis of Dyckerhoff WEISS DECOR. It is made up of a total of 148 elements and covers a total surface of 1,422 m².

Three sides of the building are made up of 81 large slabs with an average size of 11.7 m². These were provided with 26 recessed round windows with an opening size of approx. 190 cm. “The high-quality appeal of the products was to be also reflected by eliminating most of the joints and by avoiding offsets at the inevitable formwork and precast element joints,” says Claus-Peter Andres from Systembau Eder. A Plafond formliner from Reckli was therefore used which allowed the block-out element to be recessed in the bottom of the formwork. Mats and bars were used as reinforcement.

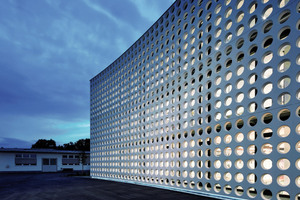

Playing with light and shadow

The fourth side of the building has a double shell. A slightly concave wall was placed in front of the glass façade on this side which features a grid of small-sized openings. It consists of 67 precast concrete façade elements with an average size of 7.0 m² each and has a total size of 470 m². This side also features the perforated grid pattern described earlier, achieved by means of 1,300 conical funnels which create an ever-changing effect by playing with a combination of light and shadow. The windows are between 38 cm and 45 cm in size. The steel formwork used to produce the façade elements was designed in-house by Systembau Eder. Special mats were used as reinforcement; in addition, plastic fibers were added during concrete production.

The look of the smooth-formed exposed concrete surfaces is reminiscent of ceramics rather than concrete. A total volume of 150 m³ of white class C30/37 concrete was used to produce the desired smooth, preferably non-porous and evenly colored surface. 2.5% of the white pigment titanium dioxide was added for two reasons: firstly, buildings with an extra white concrete surface appear bright even under an overcast sky and, unlike gray concrete surfaces, do not darken after a downpour of rain but retain their specific esthetic effect and therefore their particular charm. Secondly, the growth of algae can be significantly reduced on this type of white concrete surface, and any adhering dirt particles can be washed off with the next rain. This effect has been clearly demonstrated by extensive studies conducted by the WilhelmDyckerhoff Institute in Wiesbaden. It permits white concrete surfaces to retain their unique esthetic appeal. The façade panels were additionally given a high-quality hydrophobic finish at the plant, which is also intended to repel dirt and ensure easier cleaning.