Sprayable, structurally dense lightweight concrete

Cement-aggregate mixtures have been sprayed for well over 100 years [1]. Developments in process and concrete engineering made since that time enable shotcretes to be processed re-liably today in both dry and wet spraying processes. The shotcretes, or spray mortars, are ap-plied and compacted at high speed, with rebound having to be limited. Non-alkaline setting accelerators and special shotcrete cements are used in order to improve the setting and hardening behavior [2], which requires an analysis of their interactions with the plasticizers to be used and the composition of the aggregate mixtures.

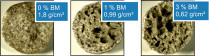

Current research is using lightweight concretes optimized in terms of their density to produce graded structural concrete elements by means of different types of robot-assisted spraying processes [3]. Ranging from reliably metering all source materials and mixing them until full homogenization of all the ingredients has been achieved via continuous transport of the mix-ture to the spraying nozzle all the way to the actual spraying process that needs to minimize rebound, the complex process chain poses a particular challenge for spraying lightweight concretes no matter which additive production process is used. The lightweight aggregate materials are exposed to high mechanical stresses which inevitably results in grain fracturing that can adversely affect the entire process chain so that the actual processing goal cannot be achieved. The lecture presents current research in concrete and process engineering that will enable even lightweight concretes characterized by a dense structure to be reliably used for the production of flat and curved structural elements by means of robot-assisted spraying processes.