Strategies for enhancing fire resistance of high-strength concrete structures

Courtesy of the American Concrete Institute, www.concrete.org, this paper focuses on strategies for enhancing fire resistance of high-strength concrete structures, written by Venkatesh Kumar R. Kodur, FACI, University Distinguished Professor and Director of Safe-D Center in the Department of Civil and Environmental Engineering at Michigan State University, East Lansing, MI.

Resiliency is a key parameter for critical infrastructure. Concrete structures exhibit a high level of resiliency in terms of safety, robustness, durability, and disaster resistance. However, while resilience is evaluated under extreme loading conditions like blast, earthquake, and impact, it is not specifically considered under fire hazards.

Fire can occur as a primary event due to natural origins (lightning or an accident) or as a secondary event (following an earthquake, blast, explosion, or impact). Worldwide, fires cause thousands of deaths and billions of dollars of damage yearly. In the United States alone, data compiled for the year 2018 by the National Fire Protection Association [1] show that:

There were 1,318,500 fire incidents;

Civilian casualties included 15,200 injured and 3,655 killed; and

Structure fires caused $11.1 billion in property damage, including $8 billion in property loss in home fires.

Fire safety in a building depends on numerous factors, including fire prevention, suppression, and extinction; successful evacuation of occupants; and the level of fire resistance (structural fire safety measures). Thus, provisions of appropriate fire safety measures are critical for safe evacuation of occupants and safety of firefighting personnel, as well as minimizing property damage, controlling spread of fire, maintaining public safety, ensuring homeland security, and maintaining economic activities.

1 Resiliency under fire

If resilience under fire conditions is not considered in the design of a structure, severe fire might lead to partial or full collapse of a structure. For example, on May 13, 2008, fire-induced progressive collapse occurred in a 13-story reinforced concrete structure: the Faculty of Architecture Building at Delft University of Technology, the Netherlands [2].

Fire started after a ruptured water pipe caused a short circuit in a coffee machine on the sixth floor of the building. The building was evacuated when the first fire alarm went off. Fire spread upward and engulfed several floors of the south wing of the building. As the firefighters struggled to control the blaze, the fire spread throughout the building. Due to the fire, parts of the north wing collapsed, followed by the collapse of the rest of the building.

2 Design for fire safety

It is impossible to prevent all major fires occurring in a structure (building), but fire risk can be mitigated through conscientious design and maintenance.

2.1 Conventional concrete structures

In structures built with conventional normal-strength concrete (NSC), structural members are designed for a fire resistance rating (FRR) in the range of 1 to 4 hours. The most important parameters setting the FRR are concrete cover depth and member thickness. For example, the minimum dimensions for concrete columns with a design compressive strength of 12,000 psi (83 MPa) or less range from 8 to 14 in. (200 to 355 mm) for FRR values of 1 to 4, respectively (Table 1).

2.2 Structures with “new” concretes

Modern high-rise buildings are taller and leaner (optimized design results in less mass and lower reserve strength) and may not exhibit the same level of resiliency as conventional reinforced concrete buildings. For example, traditional solid concrete slabs are replaced by hollow-core or composite-deck slabs; solid reinforced concrete beams are substituted by I-girders, T-beams, or double-tee beams. These changes typically result in lower mass, lower reserve capacity, and lower fire resistance. Also, new concrete types (high-strength concrete [HSC], high-performance concrete, or ultra-high-performance concrete) are designed to have higher strength, have higher stiffness, and be more durable. They have a low water-cementitious materials ratio (w/cm), a high percentage of cementitious materials as cement replacement, and various performance-enhancing chemical admixtures, resulting in a dense, compact, brittle material with low permeability. Fire behavior of these new, higher-strength concretes differs from that of conventional, normal-strength concretes. The new concrete mixtures experience faster degradation of strength and stiffness, and they are more susceptible to fire-induced spalling.

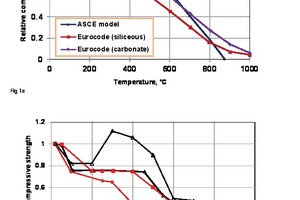

Up to temperatures of about 450°C (840°F), HSC exhibits greater loss in compressive strength with temperature than NSC [4]. Fig. 1 shows the relative compressive strength (ratio of compressive strength at a given temperature to that at room temperature) as a function of temperature for HSC and NSC. Similarly, HSC also experiences a higher rate of elastic modulus degradation with temperature; however, the thermal properties (thermal conductivity, specific heat, thermal expansion, and mass loss) of HSC at elevated temperatures are like those of NSC [5].

Spalling is caused by the buildup of pore pressure during heating. HSC is believed to be more susceptible to this pressure buildup because of its low permeability compared to NSC. At 300°C (572°F), the pore pressure can reach about 8 MPa (1,160 psi), and this exceeds the tensile strength of HSC (about 5 MPa [725 psi]). Data from various studies show that predicting fire performance of HSC, particularly spalling, is very complex because it is affected by a number of factors [6, 7]. While fire-induced spalling might occur in all concrete types, HSC is more susceptible than NSC due to its low permeability and lower w/cm. In several tests of HSC specimens, it has been observed that spalling is often of an explosive nature [4, 5, 8] and can occur in the early stages of a fire. Therefore, spalling might endanger the safe environment for evacuation of occupants and might pose a risk for firefighting personnel. Fig. 2 shows a comparison of spalling in loaded reinforced NSC and HSC columns after full-scale fire resistance tests [9].

3 Experimental and numerical studies

The structural behavior of concrete members under fire conditions is generally evaluated through standard fire resistance tests on reinforced concrete members or using numerical models. Standard fire resistance tests, though useful in evaluating comparative fire performance, have some drawbacks and do not provide realistic fire performance assessment. However, data from these standard tests on conventional concrete members have been used to develop current code provisions for reinforced concrete structural members.

A review of literature indicates that, in recent years, there has been some effort in studying the fire behavior of HSC columns through fire resistance experiments under standard fire conditions [10-12]. Data from these fire tests, as well as limited numerical studies, can be used to quantify the behavior of HSC columns under fire conditions.

3.1 Fire testing of columns

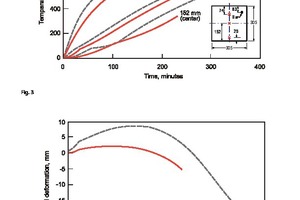

Typical results from fire resistance tests involving NSC and HSC columns are shown in Fig. 3 and 4, where temperature and deformation progression are compared as a function of fire exposure time [9]. The columns were of a square cross-section measuring 305 × 305 mm (12 × 12 in.) and 3,810 mm (150 in.) long with a 28-day compressive strength of 34 MPa (4,900 psi) for the NSC column and 83 MPa (12,000 psi) for the HSC column.

The variation in cross-sectional temperatures for the NSC and HSC columns as a function of exposure time is shown in Fig. 3. These temperatures are shown for various depths (at reinforcing bar location, quarter depth, and mid-depth) from the surface along the centerline at mid-height of the column. Temperatures in the HSC column are generally lower than the corresponding temperatures in the NSC column throughout the fire exposure. This variation can be attributed in part to the variation in thermal and mechanical properties of the two concretes and to the lower porosity of HSC. The low porosity of HSC affects the rate of increase of temperature in HSC until the cracks widen and spalling of concrete occurs. Large cracks occur in the HSC column only after approximately 3 hours of fire exposure. It can also be seen that the failure of the HSC column occurs when the temperature at central depth of the concrete core reaches 350°C (662°F), at about 240 minutes; however, the failure of the NSC column does not occur until the temperature at the central depth of the concrete core reaches 650°C (1,202°F), at about 350 minutes.

Fig. 4 shows the variation of axial deformation with time for the NSC and HSC columns. Both columns expand until the reinforcement yields. They then contract, leading to failure. The initial deformation of the column is mainly due to the thermal expansion of both concrete and steel. In the case of the HSC column, the deformation is significantly lower than that of the NSC column. This can be attributed partly to the lower thermal expansion and the slower rise in temperature in the HSC column during the initial stages due to the low porosity of HSC. When the steel reinforcement in the column gradually yields because of increasing temperatures, the column contracts. There is significant contraction in the NSC column leading to gradual ductile failure. The contraction in the HSC column is much lower. This can be attributed to the fact that HSC becomes brittle at elevated temperatures and the strain attained at any stress level is lower than that attained in NSC for any given temperature.

In fire tests, the time to reach failure is defined as the fire resistance of the column. For the NSC column, the fire resistance is approximately 366 minutes, whereas for the HSC column, it is approximately 225 minutes (shown in Fig. 3 and 4). The decreased fire resistance for the HSC column can be attributed to faster degradation of thermal and mechanical properties as well as occurrence of spalling.

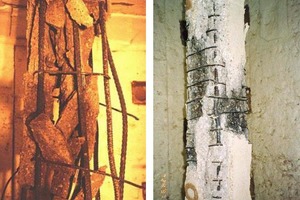

Spalling, which results in the loss of concrete sections during fire, exposes deeper layers of concrete to fire temperatures, thereby increasing the rate of transmission of heat to the inner layers of the structure, including the reinforcement. Based on the observations during and after fire resistance tests, there was no spalling in the NSC column. There was, however, significant spalling at the corners of the HSC column toward later stages of the test and prior to failure (Fig. 2). The reinforcing bars in the tested HSC column were fully exposed to fire during the later stages of fire.

3.2 Numerical methods

In the last two decades, a series of material property tests on HSC, as well as fire resistance experiments on HSC structural members, has been carried out to evaluate the performance of HSC members under fire conditions [5, 10, 11, 13]. Data generated from fire tests were used to validate finite element-based numerical models developed for tracing the fire response of HSC members under various configurations. The validated models were applied to conduct a set of parametric studies to quantify the influence of critical factors on fire response of HSC structural members [12].

4 Fire performance factors

Fire performance of concrete structures is influenced by several factors, and the key factors are summarized here.

4.1 Fire intensity

Fire intensity affects the extent of spalling and thus can indirectly influence fire resistance of concrete members. The extent of spalling in HSC members exposed to severe fires characterized by rapid heating rates or high fire intensities (for example, a hydrocarbon fire) is much higher than that under typical “building fire” exposures [12, 14, 15].

4.2 Aggregate type

In general, fire resistance of NSC and HSC members made with carbonate aggregate is about 10% higher than for concrete members made with siliceous aggregate [12, 16]. This is due to the lower thermal conductivity and higher specific heat of carbonate aggregate, which lowers the temperature rate in concrete members.

4.3 Concrete strength

Concrete strength can have a significant influence on the fire resistance of concrete structures. The higher concrete strength is typically achieved by adding supplementary cementitious materials such as silica fume to the mixture. The permeability reduces with increasing silica fume content (or content of other additives), leading to greater incidence of fire-induced spalling [5, 17]. Results from tests and numerical studies have shown that concretes with strengths higher than 70 MPa (10,100 psi) exhibit faster degradation of strength and are vulnerable to fire-induced spalling due to a significant reduction in interstitial voids.

4.4 Concrete moisture content

Concrete structures with higher moisture content (relative humidity [RH]) are prone to greater spalling [6]. Due to low permeability, concrete structures built with HSC can retain high moisture content for long periods of time. Fire resistance tests on full-scale HSC columns have shown that significant spalling occurs when RH is higher than 80% [18].

4.5 Concrete density

The effect of concrete density on fire performance has been studied through fire tests on columns, slabs, and blocks made of normal- and lightweight concrete [10, 14]. The extent of spalling in concrete members is much greater when lightweight aggregate is incorporated in the concrete mixture. This could be partly attributed to higher free moisture present in lightweight aggregate, which creates higher vapor pressure under severe fire exposures.

4.6 Specimen dimensions

Generally, the fire resistance of a concrete member increases with member dimensions due to increased sectional capacity and thermal mass. However, the risk of explosive thermal spalling in HSC members increases with an increase in member size [6]. This is because heat and moisture transport through a member is inversely related to its size, and larger structures have greater capacity to store more thermal energy.

4.7 Sectional configuration/shape

Sectional configuration has a significant influence on the fire resistance of a concrete member [19]. For example, a hollow-core slab of equivalent cross-section exhibits lower fire resistance as compared to a traditional solid slab. In a solid slab, the temperature transmission from fire-exposed surface to unexposed surface is mainly governed by conduction of heat, whereas such temperature transmission through a hollow-core slab occurs via conduction in the solid concrete portion and convection and radiation in the hollow cores. This causes significant variations in cross-sectional temperature profiles in these two slab types.

In addition, due to the lower mass of concrete, hollow-core slabs (or T or I section beams with slender stems) experience faster transmission of heat to the interior and unexposed side of the slab compared to solid slabs. Fire resistance of concrete columns is influenced by the shape of the cross-section. A column of circular cross-section will have higher fire resistance than a column of square or rectangular section, of equivalent cross-sectional area. The lower fire resistance in square or rectangular columns is due to the edge (higher heating at the corners) effects [12].

4.8 Load intensity and type

The type of load and its intensity significantly influence spalling and the resulting fire resistance. Higher load intensity leads to lower fire resistance [10, 17]. The effect of load level is more pronounced in HSC structural members because the temperature-induced strength loss is greater for HSC than for NSC. This is because a loaded structural member is subjected to stresses due to structural loading in addition to the pore pressure generated by steam. Furthermore, the extent of spalling is higher if the load is of an eccentric (or bending) type because this will induce additional tensile stresses.

4.9 Fiber reinforcement

The presence of steel or polypropylene fibers in a concrete mixture minimizes the extent of fire-induced spalling and thus enhances fire resistance of any concrete member. Results from experimental studies show that the addition of polypropylene fibers to concrete (about 0.10 to 0.15% by volume) minimizes spalling in HSC structural members under fire conditions and thus enhances their fire resistance [10, 12, 14]. The polypropylene fibers melt at 160 to 170°C (320 to 340°F) and create pores in concrete that help dissipate temperature-induced pore pressure. Alternatively, steel fibers in concrete can also minimize spalling and enhance fire resistance of HSC structural members. The addition of steel fibers to concrete (about 1.75% by weight) enhances the tensile strength of concrete and slows down the degradation of tensile strength with temperature.

This increased tensile strength helps overcome temperature-induced tensile stresses generated by the pore pressure and thus minimizes the occurrence of spalling [15]. Steel fibers might also slightly improve heat transmission into the concrete, thus reducing thermal gradients and associated high tensile strains beneath the heated surface. Fig. 5 shows the state of HSC columns with different fiber configurations after fire resistance tests [20].

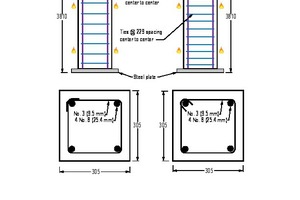

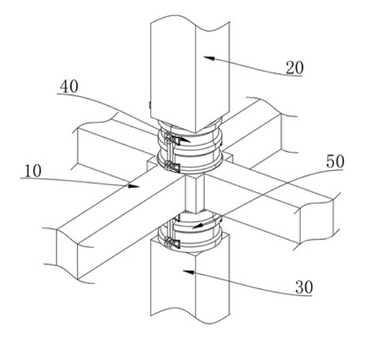

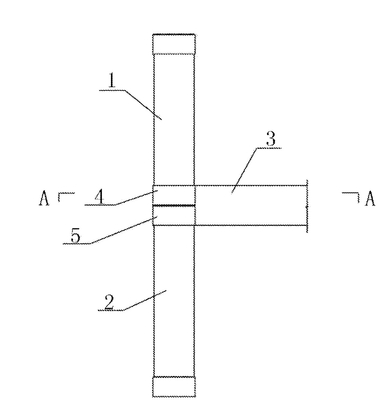

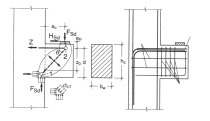

4.10 Reinforcement configuration

Results from fire resistance studies clearly show that the layout of ties and confinement of columns have an influence on the fire performance of HSC columns [11, 17]. Higher fire endurance in HSC columns can be achieved by providing improved tie configuration (provision of 135-degree hooks back into the core of the column and through provision of crossties) and with closer spacing of ties (at 0.75 times that required for NSC columns). Fig. 6 shows a conventional and modified tie configuration in an HSC column. Much of the beneficial effect comes from using 135-degree hooks rather than 90-degree hooks.

Spacing of transverse reinforcement (ties) has only marginal influence on fire resistance. Fig. 7 shows photographs of the column specimens with conventional and improved tie configuration after a fire resistance test as reported by Kodur and McGrath [17].

5 Enhancing fire performance

Based on numerous fire tests and numerical studies, a set of guidelines has been proposed for enhancing fire performance of HSC structural members [20]. The recommendations to minimize fire-induced spalling in HSC structural members and enhance fire resistance, even for concrete with strength as high as 110 MPa (16,000 psi), include:

1) Proper concrete mixture design:

Use of carbonated aggregate (limestone),

Lower moisture content, and

Less silica fume (below 10%);

2) Use of fiber reinforcement:

Polypropylene fibers at 0.10 to 0.15% by volume,

Steel fibers at 1.75% by weight, and

Hybrid fibers at 0.12% polypropylene fibers plus 0.6% steel fibers by volume;

3) Proper tie configuration and spacing:

Bending of ties at 135 degrees,

Closer tie spacing (0.75 of the conventional spacing), and

Use of crossties;

4) Designing for:

Lower load intensity, and

Lower eccentric loads; and

5) Other solutions:

Applying a protective layer on the concrete member, and

Incorporating mesh reinforcement outside the reinforcement cage.

Fire performance of HSC structures can also be enhanced by performance-based design for realistic (actual) conditions based on rational engineering principles through application of analytical and numerical methods [16, 21]. This type of design should account for system-level response, realistic loading and restraint, temperature-dependent material properties, and realistic failure criteria.

6 Summary

There are a few performance problems and knowledge gaps related to conventional concretes under fire conditions. However, there are serious performance issues and significant knowledge gaps related to modern concretes under fire conditions. HSC structural members exhibit poor fire performance in comparison to conventional concrete structural members, especially due to occurrence of fire-induced spalling. Simple modifications such as improved tie configurations and the addition of fibers can overcome these performance problems and help to achieve better fire resistance and thus higher resiliency.

Also, through fire resistance experiments and rational fire engineering approaches, it is possible to develop unique strategies for enhancing fire performance of HSC structural members.