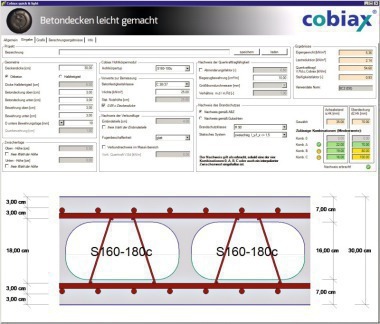

Structural concrete components with reinforcement glued in slots

Strengthening structural concrete members by augmenting cross-sections or gluing supplementary reinforcement onto surfaces or into slots yields benefits resisting service loads. Since members are strengthened when loaded and deflected, the self-weight is still borne by the initial cross-section only. In statically indeterminate systems, temperature induction applied during strengthening enables to activate the total cross-section to carry the dead load. Due to a linear, vertical temperature gradient, the concrete member then faces a constraining moment which locally compensates the bending moment from dead load. Once strengthening is completed, the induction of temperature is stopped so that stresses from dead load uniformly distribute over the new total cross-section locally.

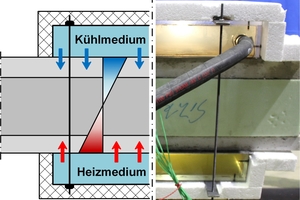

This paper discusses the mechanical impact of temperature gradients on different static systems, the technical implementation of temperature induction, and potential fields of application. The methodology of strengthening is demonstrated for a two-span concrete beam subsequently augmented by reinforcement glued into slots. Here, the bending moment from dead load is locally neutralized by directed temperature gradient at the internal support. Temperature induction is implemented through cooling and heating water circuits. Testing reveals nearly identical stress-levels in the original and subsequently installed reinforcing bars. However, successful application under ambient conditions on-site combines reliable simulation [1], measurement [2] and control of temperature fields accounting for climatic variation.