Successful commissioning of plant extension at PT. Rekagunatek Persada

After the successful installation of a central transfer table production line in 2017, Indonesian precast producer PT. Rekagunatek Persada commissioned the next extension to its plant in summer 2018: a production line for the manufacture of prestressed solid floor slabs.

Based in the Indonesian capital, Jakarta, PT. Rekagunatek Persada is a subsidiary of PT Indonesia Pondasi Raya. In 2017, the company commissioned a central transfer table production line supplied by Weckenmann Anlagentechnik GmbH & Co. KG for the manufacture of precast wall and façade panels. The next stage of the master plan for expanding the newly established precast plant involved the installation of another production line for the manufacture of prestressed precast floor slabs.

PT. Rekagunatek Persada again contracted Weckenmann, one of the leading international equipment manufacturers for the precast industry, with designing, engineering, and supplying the new production line. In Indonesia, Weckenmann is represented by PT Melindo Dipta, a member of the Melchers Group. Weckenmann joined forces with its Indonesian customer to design and engineer the new plant extension – a facility for the manufacture of prestressed solid floor slabs. This second addition to the plant has a stationary layout including a total of six 120 m long casting beds and was commissioned in summer 2018.

The new extension comprises the following components:

six 120 m long casting beds with prestressing equipment

two half-gantry concrete spreaders

two utility carts

a run-off carriage

a central bucket conveyor system

a cleaning and oiling unit

a saw unit for cutting off prestressing strands and

a complete shuttering system for three different production heights.

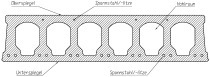

The new floor slab facility provides the engineering solution for producing up to 2,400 mm wide prestressed precast floor slabs. The casting beds include a surface finishing stage that ensures architectural concrete quality if and when required. Mold faces are perfectly level and smooth.

Mold/stopend system

The bearing capacity of 500 kg/m² provided by the casting beds allows the manufacture of up to 200 mm thick precast elements. The system of shuttering profiles has been initially designed for thicknesses of 65 mm, 80 mm, and 120 mm. The side profiles of the casting beds have a hinged design for easy prestressing and demolding. They are also easy to replace for the quick changeover to other thicknesses or different grouting joint contours. The ergonomic design of this new shuttering system makes it easy to operate; it includes a quick-change system for the swift replacement of side profile designs.

Tried-and-tested prestressing equipment

The system for prestressing the wire strands includes abutments embedded in the building foundation on both sides, i.e. at the faces of the casting beds. These abutments include hydraulic tension release cylinders also installed on both sides of the casting beds. The prestressing unit has been designed for a maximum prestressing force of 2,000 kN. Prestressing wire coils are provided on reels for further processing. Pulleys guide the strands to the cleaner/oiler unit, where they are fixed on a specially designed pull bar. From there, the strands are pulled over the entire length of the casting bed separately for each floor slab, and placed on the casting bed.

A single-wire tensioning press then applies the specified force for prestressing the strands. Strand spacings result from the specific pattern of openings inserted in the cross-perforated plates positioned on both sides of the prestressing bed. After concrete curing, tension relief of the strands is ensured by the above-mentioned hydraulic tension release cylinders arranged symmetrically on both sides of the casting bed.

Shuttering systems

The X-Uni-S shuttering system was selected for the prestressed floor slab range because this system is perfectly suitable for the projecting transverse reinforcement for various element thicknesses. Longitudinal profiles are fixed through magnet boxes that can be attached quickly and easily using adapters and twist-lock fittings. Front profiles are slotted to accommodate continuous wire strands; these profiles are placed above the strands. Front profiles are elastically supported to enable tension relief and to absorb the relief pressure.

After curing, they are removed and placed on the utility cart via a specially designed crossbar. Two utility carts with magazines running on floor rails alongside the casting beds ensure appropriate handling and interim storage of profiles. Each of the utility carts is equipped with a handling crane that facilitates and accelerates mold placement and removal.

Concrete spreading

Two half-gantry spreaders ensure concrete pouring into the six casting beds. Each of these spreaders has a span that covers three casting beds. Concrete spreader buckets can move in the transverse direction across all three casting beds. Each of the buckets can be filled with up to 3.0 m³ of concrete. Separate valves enable precise and accurate batching across a width of 1,200 mm.

Variable concrete batching with integrated lifting gear

Discharge hoppers can be turned about a 90° angle for the optional manufacture of prestressed beams on the casting beds. This design aligns the concrete spreading pattern with the narrower beam shape. Lifting gear with a maximum height of 1 m ensures that discharge hoppers are height-adjustable, as is necessary for beam production due to the design of the shuttering system. As a result, the casting beds can be used for producing prestressed piles or beam-shaped sheet-pile wall units. The two concrete spreaders have an output of up to 180 m³ of fresh concrete per shift. The spreaders are equipped with height-adjustable, vibrating leveling screeds to level and smooth the concrete surface during pouring.

The concrete is compacted simultaneously with the pouring process. The compaction units also installed on the spreaders include seven high-frequency internal vibrators with variable frequency control that can be hydraulically immersed in the concrete. The concrete spreaders are fully remote-controlled.

Bucket conveyors ensure concrete feed

The mixing unit continuously feeds concrete to the spreaders via a central system of two bucket conveyors. Each of these conveyors has a capacity of 2 m³ of concrete and moves back and forth between the mixer and the spreaders. The bucket conveyor is controlled so that it closely follows the spreaders, thus always ensuring timely concrete feed. The operator of the relevant concrete spreader triggers additional concrete feed if and when required. The bucket conveyor control unit is connected to the mixer system to enable signal exchange for ensuring just-in-time concrete supply. Prior to lifting the floor slabs, wire strands are cut off by a saw unit, which travels alongside the casting beds and includes an axially controlled, high-speed saw blade for quick and clean cutting.

After lifting, finished slabs are stacked on strip footings along the casting beds and then conveyed to the storage area. A run-off carriage travels on rails underneath the stacks; it provides a capacity of up to 30 t for lifting heavy stacks of slabs and putting them to storage. This logistics system relieves the cranes installed in the factory building of some of their loads because the cranes have to overcome only short distances for stacking purposes.

Summary

This newly installed production line has an output of up to 1,400 m² of prestressed precast floor slabs per shift. Its sophisticated formwork concept is combined with a state-of-the-art production logistics system. Equipment and machinery were designed such that they make it possible to add precast beams to the product range. Weckenmann and PT. Rekagunatek Persada deliberately decided to not fully automate the production line. Instead, the partners focused on high product quality in combination with state-of-the-art mechanization of the production process whilst also concentrating on its ergonomic layout and high operational reliability.

All of these factors contribute to the commercial viability of this investment made by PT. Rekagunatek Persada.

CONTACT

Weckenmann Anlagentechnik

GmbH & Co. KG

Birkenstraße 1

72358 Dormettingen/Germany

+49 7427 94930