Successful planning and execution of summer and

winter concreting

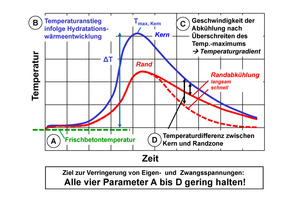

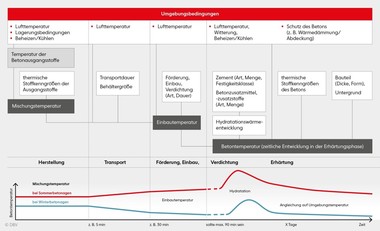

Concreting at high summer or very low winter temperatures poses special challenges for planning and construction. High fresh concrete temperatures lead to earlier slump loss and faster hardening of the concrete. Consequently, there is a higher heat release due to hydration heat, which can have unfavorable effects depending on the component geometry and constraints in the construction. Large temperature differences between the core and boundary zones lead to significant inherent tensions, while high core temperatures can trigger high restraint stresses during the cooling phase if

restraint points or frictional restraints are present. These risks can be mitigated by favorable design, concrete engineering and execution

measures (Fig.).

At low winter temperatures, on the other hand, care must be taken to minimize temperature losses during transport, conveying and concrete placement. For this purpose, protective measures should be planned, which generally constitute a special ancillary service that must be tendered separately.