Sustainable acceleration of concrete hardening

by means of Sonocrete

The ultrasonic premixer of Sonocrete provides for faster concrete hardening. Precast concrete elements can be demolded earlier, or more sustainable cement types or less heat can be used in their production which is more climate-friendly consequently. Now, the technology has managed to step out of the laboratory, proving its industrial suitability at the precast concrete plant of Mattig & Lindner located in Forst/Lausitz.

Sonocrete improves the sustainability of concrete

Concrete producers are faced with a lot of challenges: The demand for concrete components will continue to increase in the future due to urbanization and an investment backlog, however, these building components will have to comply with ever more ecological requirements, while reducing CO2 emissions in their production.

The founders of Sonocrete GmbH, Dr. Christiane Rößler and Ricardo Remus, have been researching on the influence of high power ultrasound on concrete hardening for several years now. Faster hardening enables precast concrete elements to be demolded faster. This either allows the manufacturers to increase the production, use a climate-friendly concrete or minimize heat curing. In some cases, the carbon footprint of concrete is diminishing considerably.

Cement and water are premixed in the Sonocrete premixing device for a short period and treated with high power ultrasound. The ultrasound leads to a cavitation in the suspension. The resulting locally extreme pressures lead to faster concrete hardening.

Until now, only a bench-scale unit was available. At the end of February, the team of Sonocrete used the early springlike days for an industrial test run. As part of the research project funded by the Federal Ministry of Education and Research (BMBF), the Sonocrete technology was used for the first time in real-life operation at Betonwerk Mattig & Lindner GmbH.

The test run began in Forst as soon as the normal operation had finished for the day.

Factory trial in Forst

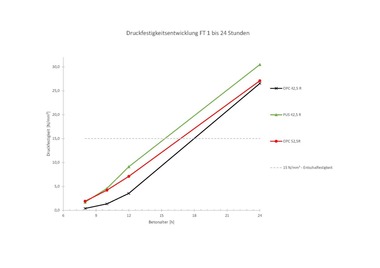

The Sonocrete equipment was unloaded and installed directly beside the concrete mixer. The tests were carried out with three different concrete mixtures, all based on the same concrete mix design, using identical raw materials. For a start, a normal concrete was mixed as a reference and afterwards two mixtures with treatment in the Sonocrete mixing device. Within a few minutes, the cement-water suspension was treated with ultrasound in the vessel of the Sonocrete device and could then be charged into the large concrete mixer. The concrete was mixed there and then cast into the formwork for floor elements.The manufactured concretes were tested thoroughly in order to determine the influence of the Sonocrete technology. In this regard, slump, temperature and fresh air void content were measured.

Findings of the factory trials

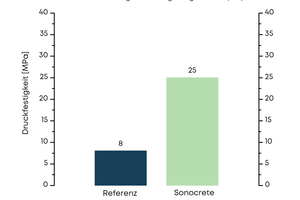

For subsequent tests of the compressive strength, standardized cubes were cast. The test results show the success of the first Sonocrete factory trials. After 24 hours, the strength of the sonicated concrete is three times that of the unsonicated concrete. It results in an acceleration of about 8 hours – thus, the formwork might be removed from the concrete 8 hours earlier due to the short application of ultrasound. Alternatively, the need of heat curing could be eliminated entirely.

In this way, Sonocrete was now able to demonstrate that an ultrasound activation of the cement suspension leads to significantly increased early strengths of concrete in real-life operation too. The test has provided the Sonocrete team with many useful information for further developing the equipment. Although some minor problems occurred – e.g., a USB cable crushed during unloading, which fortunately could be replaced by an audio stick. Together with the equipment that passed the acid test, 33 cubes and three Filigran floor slabs the team returned to Cottbus.

Michael Lindner, General Manager at Mattig & Lindner GmbH, states: „We are excited about the cooperation with the young research team and expect major sustainability effects by using the new technology.“ Ricardo Remus, founder of Sonocrete, adds: „We are very satisfied about how the equipment has run. Everything worked very well, and we are very grateful that we were allowed to test the equipment here in Forst.“

After the successful first real-life test, further factory trials are planned in the summer of 2021. Then, the focus will be on the control unit. In addition, the quantity of the cement-water suspension to be treated with ultrasound will be tripled. This year, Sonocrete is starting an early access program, equipping selected precast concrete plants with Sonocrete equipment already before the market launch. A solution for the ready-mixed concrete industry is under preparation as well.