System for changing mixing tools reduces maintenance costs

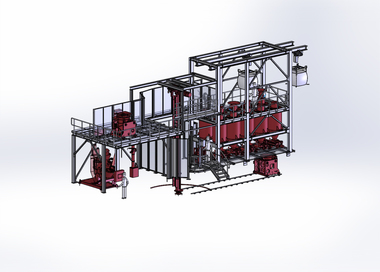

Tool change is part of the normal routine for mixer operators. The mixing tool does most of the work during raw material preparation, and its condition has a major influence on the quality of the end product. Eirich has developed a new system which reduces downtime by a substantial margin and cuts cost. It is also ideally suited for low-cost retrofitting.

Quick-change system

for the beaters

Changing mixing tools or mixing tool parts in a mixer used to take as long as several hours.

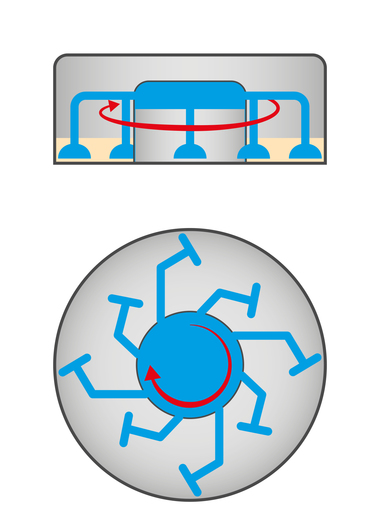

Eirich has now developed a quick-change system for the beaters. Replacement of the beaters is now a simple procedure and only takes a few minutes. Users who have migrated to the new system report a drastic reduction in downtime and maintenance costs. One very clever feature is the ability to easily swap beaters that have wear reserves with beaters which are located in zones with greater stress and show higher wear, making maximum use of the material.

No need to replace the rotor

Migrating to the new system is easy, because there is no need to replace the rotor or purchase a new rotor shaft. The ability to continue using existing spare parts is a big advantage.

The new SmartFix system, for which a patent application has been filed, is available as a retrofit or conversion kit for all Eirich production mixers with capacities of 75 liters or more. Eirich customers now have an additional way of increasing production efficiency and profitability.