The aesthetics of resource-efficient construction

The Rosenstein Pavilion was designed as a lightweight concrete shell that sets a prime example of how to apply appropriate design methods to our built environment in order to increase its resource efficiency. This pavilion was designed for an exhibition in the Rosenstein Palace building in Stuttgart. It creates a link between research into reducing material consumption and bionics-based design principles conceived to create buildings that are both technically efficient and aesthetically appealing.

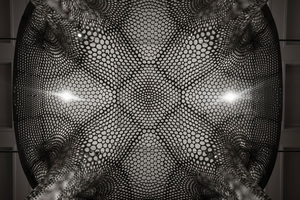

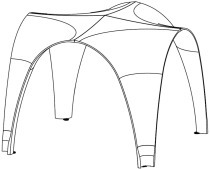

The Rosenstein Pavilion (Fig. 1) was designed and built for the “Baubionik – Biologie beflügelt Architektur” (Structural Bionics – Biology Inspires Architecture) exhibition shown at the museum located in the Rosenstein Palace building in Stuttgart. This exhibition showcased findings of the collaborative research center TRR-141 on “Biological Design and Integrative Structures”, which was to develop bionics-inspired engineering solutions for a sustainable built environment. Within this framework, the pavilion demonstrated how design principles derived from biology can be implemented with the aim of enhancing the performance of load-bearing structures. Inspired by bones and exoskeletons, the structure of the Rosenstein Pavilion was optimized by aligning the distribution of materials with the load patterns acting on the structure. As a result, its weight was reduced by 40% compared to a solid shell without compromising its bearing capacity.

Research context

The concept of the pavilion was based on research into so-called functionally graded concretes, which has been conducted for several years at the Institute of Lightweight Structures and Conceptual Design (ILEK), University of Stuttgart, chaired by Prof. Werner Sobek. This research was initiated in response to the current overconsumption of natural raw materials and the environmental impact of cement production.

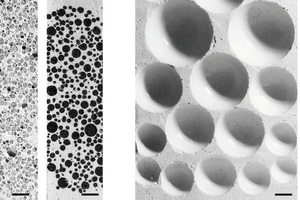

The technology behind functionally graded concrete provides an integrated solution for minimizing the weight of structural components by minutely adjusting the mechanical properties of the concrete to a defined load profile. Such components can be produced with functionally graded lightweight aggregates (Fig. 4a), hollow concrete spheres (Fig. 4b), or custom formwork designs (Fig. 4c). Latest analyses and tests of components in bending, such as beams and floor slabs, showed that the functional gradation of a structural component can reduce its weight by up to 40% without compromising its bearing capacity. The Rosenstein Pavilion was to explore the potential of functional gradation as a resource-saving strategy applied to the architectural object as a whole.

Project context

The Rosenstein Pavilion was conceived as a central object within an exhibition space in which the structural principles of high-performance plant and animal tissues were presented. The design concept of the pavilion relied on the biological strategy of structural optimization as a natural counterpart to resource efficiency in the construction industry. Furthermore, the design process as such was inspired by the unity of form and function observed in nature as a result of morphogenesis. This process applied an integrative approach to developing the form, structure and distribution of materials.

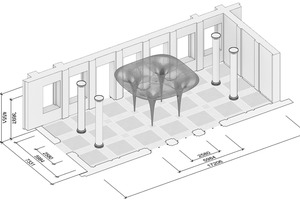

The pavilion was designed as a three-dimensional object that organizes the space around it. Embedded in the neo-classic interior of Rosenstein Palace, its lightweight appearance also sets a contrast to the old structural system of the museum building. On the one hand, the design parameters of the pavilion were dictated by the rhythm of the architectural elements within the space, including the locations of and distances between columns as well as its structural height and external dimensions. On the other hand, a shell typology was chosen to establish a counterpart to the solid system of beams and columns in order to amplify ...

You can read the complete text in the Beton Bauteile 2019 yearbook Beton Bauteile 2019 (see below).