Concrete light – A bridge made of carbon reinforced and infra-lightweight concrete

Making construction with concrete more resource-efficient and climate-friendly is one of the most important goals in civil engineering. Within the DFG-funded priority program 1542 “Concrete light”, bionic and mathematical design principles were applied for this purpose in order to use innovative concretes efficiently. A bridge made of carbon reinforced and infra-lightweight concrete was developed at TU Dresden and set up in the Deutsches Museum in Munich to demonstrate this approach.

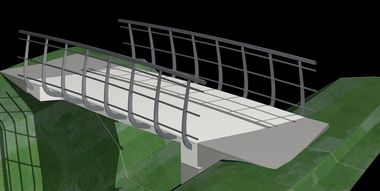

The exhibition bridge is designed as a filigree structure consisting of two gently inclined columns and a three-section, 9.50 m long and 1.20 m wide superstructure. Above all, the design and structural options that lightweight concrete and carbon reinforced concrete offer are demonstrated by the slender V-shaped columns and the construction weight of only 2.1 metric tons. The shape optimized for force flow and the sandwich design of the superstructure play a major role in this regard.

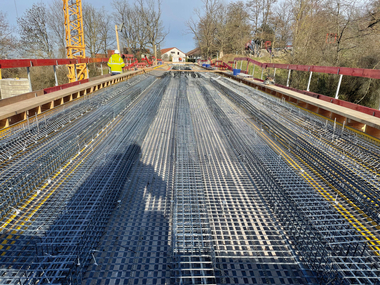

The three-layer structure varies in height between 60 and 160 mm. The biaxially curved underside and the flat top layer are made of 20 mm thick carbon reinforced concrete. The space in-between is filled with infra-lightweight concrete with a density of about 800 kg/m³, the composition of which was designed by HeidelbergCement.

Based on the 3D modeling of the bridge, the geometry was optimized in terms of load transfer and design, and the formwork was manufactured from milled plywood. After successful production and testing of an identical test bridge, five prefabricated segments were transported to the installation site at a height of approximately 3 m at the Deutsches Museum. A variably adjustable support system was used to align the segments, and the infra-lightweight infill and carbon reinforced concrete top layer were cast on-site.

The optimized interaction of carbon reinforced and infra-lightweight concrete in this hybrid structure ultimately allows for significant resource savings and thus CO2 reduction compared to a steel reinforced concrete structure with comparable load-bearing capacity.