The new AMM and AKK series of mesh welding lines

Eurobend GmbH is setting new standards in mesh production by offering the AMM and AKK series of innovative flexible mesh welding lines covering every mesh application. Both the AMM & AKK are well established and can be found operating in leading precast and mesh producing companies in Europe, Russia, Middle East and North America.

The AMM series has the latest groundbreaking design of mesh welding lines for the production of precast mesh and mesh with openings used in precast wall panels. It uses the wire feeding system patented by Eurobend, which ensures elimination of time-consuming diameter and coil changeovers. Any type of mesh can be produced instantly without manual adjustments.

Models for economic and high output

Different models are available for both the economic and high output production of mesh, offering maximum flexibility without changeover adjustments, due to unique design and functionality of the wire feeding and welding module.

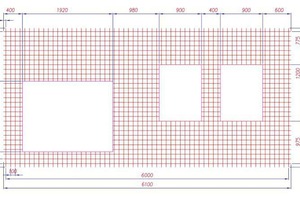

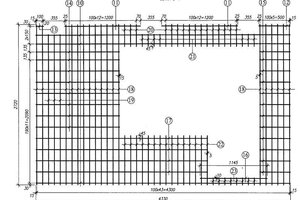

The models of the AMM series are designed for the production of standard and customized mesh designs and sizes, allowing the welding of uneven line and cross wire lengths and different line and cross wire diameters within the same panel, and mesh used in various precast wall panels with openings – for doors and windows – due to the servo-driven moving welding head.

Depending on the machine version, line and cross wires are fed fully automatically from two Flexi-line Rotor straightening and cutting machines with patented automatic diameter changing system or from precut wires/bars.

The models are equipped with Single or Double Y-axis programmable, servo-motor driven welding head configuration with four or eight welding points (PL X-Y AMM Series) or Multi-head configuration with up to 81 fixed welding heads (PLC AMM Series).

AKK series

The new AKK welding line has set new standards in mesh production. This new, innovative design eliminates all idle times and at least doubles productivity in comparison to conventional welding lines. All advantages from off-coil and pre-cut welding machines and more, are combined in one machine. The AKK series is capable of producing large and small batch orders consecutively without any downtime. The concept behind the AKK series allows automatic mesh spacing & dimensions changes, making it the only flexible high production coil-fed mesh welding line, as it can produce all mesh types instantly without any adjustments. Also, it offers a compact system layout requiring minimum floor space requirements.

With the new AKK there are no downtimes when changing wire coils, wire diameters, wire spacing or mesh dimensions.

It is equipped with the patented “Automatic Wire Orientation System” (AWOS), which allows the use of a high speed roller straightening module for line wire feeding. The AWOS absorbs all wire straightening imperfections from the roller straightener. This unique Automatic Wire Orientation System ensures perfectly flat mesh panels regardless of wire and straightening quality. It is fully programmable and capable of processing all types of material, smooth or ribbed.

Minimal stock of wire spools and coils

A single coil replaces all line wire de-coiling stations, where a double line and cross wire de-coiling station ensures continuous operation. As a result of the above, minimal stock of wire spools and coils is required and the necessity for large stock of ready mesh as in conventional welding lines is eliminated. Furthermore, multiple diameter changes during one day/shift can be achieved efficiently due to single coil line wire feeding.

The AKK series is equipped with independent heavy duty hydraulic or pneumatically operated welding heads. Due to programmable cross wire placement, different cross wire spacing is possible within the same mesh. Mesh advancing is ensured either through a servo-driven carrier offering exceptional accuracy, or through a compact layout servo-driven roller feeder. The in-line mesh turning and collection table is equipped with adjustable mesh aligning flaps for perfect mesh batches. Roller or laterally discharging chain conveyors with height adjustment and in-line mesh bundling stations are available. The AKK series has remote access via Internet connection for troubleshooting and routine maintenance.