ThermoPin made to measure

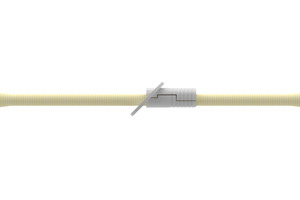

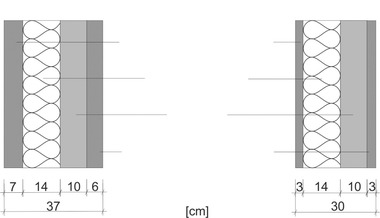

The ThermoPin anchor system of B.T. innovation GmbH is a connection anchor made of glass-fiber reinforced plastic (GFRP) with a firmly attached sleeve. The anchor is used for the connection of facing layer and load-bearing layer of sandwich walls or core-insulated double walls. The length of the bar and the position of the sleeve vary depending on the component thickness and kind of installation. Now, a flexible sleeve allows for considerably faster manufacture and supply of ThermoPin anchors which are precisely tailored to the component.

For common ThermoPin configurations with bar lengths starting from 130 to 565 mm and individual versions with a sleeve position limiting the installation depth, there are more than 5,000 potential design versions for the ThermoPin anchors hypothetically. In practice, so far, BT innovation kept a large number of pins as standard sizes in stock, apart from this production was carried out on an order-related basis. Such storage is cost-intensive and production is not always possible just in time. It was possible to reduce storage costs considerably and minimize delivery times by the introduction of a flexible sleeve.

Still conical, but slipped on anyway

A characteristic feature of the ThermoPin anchors is their conical shape at the ends. Thus, a high force transmission in the concrete layer is achieved through positive locking. In addition, a reduction of the cross-section leads to an optimized material usage and thermal transmission coefficient. However, because of the conical shape of the ends, a sleeve cannot be slipped on the anchor bar directly. Therefore, BT innovation developed a folding sleeve which can be attached to the ThermoPin from the side in a precise way subsequently. The custom-specific „production“ is reduced to the assembly of already prefabricated items in stock consisting of anchor bar and sleeve. Putting on an already prefabricated sleeve allows for significantly faster ability to deliver. Moreover, costs are saved by the reduced stock-keeping. And the customers benefit from both.

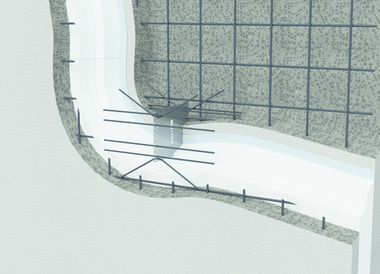

Designed for all cases (and) at European level

The new connection anchor is available for mere horizontal installations as well as for diagonal installation. When installed horizontally, it is acting as a connecting element of two concrete layers which transfers all horizontally acting forces. Additional diagonally inserted ThermoPins, on the contrary, allow for the load transfer of self-supporting facing layers. Core-insulated walls with self-supporting facing layers are state of the art and are more and more realized for structural reasons and in terms of energy efficiency. The ETA 19/0498 already granted for the ThermoPin in 2019 was extended for the application of load-transferring diagonal anchors in 2021. Hence, BT innovation is the only manufacturer of connection anchors providing for a thermal separation of self-supporting facing layers with a European Technical Assessment in Germany at present.

CONTACT

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+49 391 7352-0