Roggeveld wind farm generators mounted on precast concrete towers

Forty seven precast concrete towers were deployed for the construction of the Roggeveld Windfarm which is owned by Independent Power Producer (IPP), Red Rocket (formerly Building Energy), and is situated in the Western Cape close to Matjiesfontein and Sutherland in the Northern Cape.

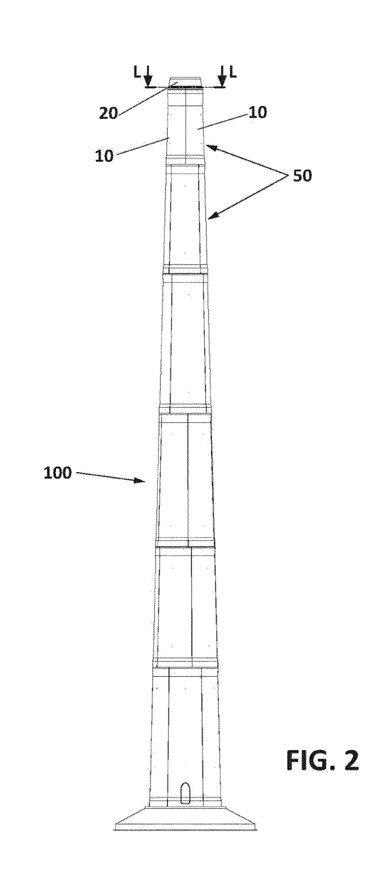

Roggeveld forms part of Round 4 of the REIPPP (Renewable Energy Independent Power Producer Program) and feeds up to 147MW into the national grid. At a height of 100m, the towers support wind-powered turbines, each with a maximum generating capacity of just over 3MW.

The towers were assembled with precast concrete segments which were manufactured by Cape Town-based precast concrete producer and Concrete Manufacturers Association (CMA) member, Concrete Units, in a joint venture with Spanish company, Windtechnic. The latter has extensive experience in the manufacture of precast concrete wind towers and provided engineering input. On completion, some 16,500m³ of concrete, 2,500 tonnes of reinforcing steel and 164,000m² of shuttering had been used.

Tower assembly and the supply and installation of turbines and blades were handled by Nordex Energy South Africa. In addition, a Nordex team of 20 staff members was permanently based at Concrete Units to ensure that high quality tolerances were met daily during the manufacture of the tower segments.

The civils contract, which included the tower bases and the roads, was awarded to Concor and Raubex Infra was awarded the electrical installation contract.

According to Concrete Units Cape Town manager, Charl Coetzee, a completed tower comprises five 20m tapered concrete sections, each section having been assembled with individual precast concrete segments.

The base section, T1, comprises four segments and was mounted on an in-situ concrete foundation. T2, which was mounted on T1, and T3, which was mounted on T2, were also assembled using four precast concrete segments each, whereas T4 was constructed with three segments and T5 required only two.

Turbines comprise a nacelle and hub which weigh a combined 140 tonnes, and three blades, each weighing 12 tonnes. Therefore each tower bears a total weight of 176 tonnes.

Sections post-tensioned by Nordex

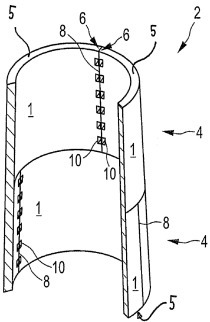

The precast sections were assembled at the tower sites. Individual segments were lifted off truck beds and then lowered vertically into position by a giant mobile crane. They were joined to matching segments using ‘bowtie’ connections. This was achieved by inserting reinforcing into hollow slots formed by the segments’ two opposing vertical channels. A proprietary high-strength grout was then pumped into the joint to create a permanent seal.

“The 20m sections were attached to each other in a horizontal plane using starter bar and ducting joints which were sealed with grout. The flawless execution of this process required extremely accurate casting and very tight tolerances,” said Coetzee.

The Roggeveld towers were designed to bend and during strong winds can move up to 700mm at their apex. This flexibility was facilitated by the use of steel reinforcing inside the tower walls. This lateral movement was counterbalanced by the installation of six 90mm steel cables, which attach the inner wall of T5 sections to the concrete base and provide additional strength to the overall structure. Once installed, they were post-tensioned by Nordex.

The precast segments, 799 in all, were cast at Concrete Units’ factory using five moulds which were imported from Italy by Nordex. Two metres long, the mould sections were attached to each other using precision-based laser technology. Moreover, to ensure the accurate layout of the steel reinforcing, Concrete Units used special reinforcing jigs.

A maximum of five segments were cast daily. Various types of inserts and sockets were cast into specific positions to accommodate the mechanical (ladders, lifts and landings) and the electrical equipment (cable trays, etc) required inside the towers. Spaces for doors were cast into every fourth T1 segment. Mould stripping took place either late into the night shift or first thing every morning by which time the segments had reached a minimum compressive strength of 25MPa.

Segments T1 and T2 sections were 5,5m and 5,0m respectively and their transportation on extendable trailers required police escorts. Because of their abnormal loading, the trucks weren’t able to use the Du Toits Kloof tunnel on the N1. Instead they were routed via Tulbach, over a distance of 350km and the journey took up to two days. However, the smaller segments, were transported using normal escorts.

In terms of concrete manufacture, the Roggeveld Wind Farm project is cutting edge and is one of the country’s largest wind farms to date.

SCC was supplied by Megamix

The tower segments were designed according to European as opposed to SANS codes. This allowed us to design up to 115MPa cube strength design rather than the 60MPa which forms part of the SANS structural concrete code. The Roggeveld tower segments were manufactured to 75MPa, the strength required to bear the loading of the turbines and to withstand the wind forces. This strength allowed Nordex engineers to opt for lighter concrete sections which added a further eco-friendly dimension to the project through lower material usage and transport costs.

Moreover, the tower sections were manufactured with Self-Compacting Concrete (SCC). Without it, the project would have been much more complex, involving external vibration and more expensive moulds.

SCC was supplied by Megamix, which has a batching plant close to Concrete Units. The SCC mix was one of the critical components of the whole manufacturing process. Rainy weather can affect the mix because the amount of water used is critical. Even a slight water overdose can cause segregation and a loss of strength which is why the slump flow of every batch was tested at Concrete Units before being pumped into the moulds.

In most instances, the higher one goes, the better the wind, and for heights above 80m, concrete towers tend to be less expensive than steel towers, thus impacting on the cost of the electricity generated positively. To date, most wind turbines in South Africa have been mounted on steel towers, most of which are imported and therefore carry a comparatively low local labour and job-creation component.

By contrast, concrete wind towers come with high local-content inputs and by default carry a much higher job generating capacity. For example, over 95% of the raw materials for Roggeveld’s concrete towers including the reinforcing steel, was sourced locally.

All the IPPs have submitted tenders for Bid Round 5 and the notices to proceed are expected to be published in March 2022. With greater heights and different designs, Round 5 towers will be able to generate up to 5.6MW each. When completed, Round 5 will generate up to 1,600MW from onshore wind energy and 1,000MW from Solar Photovoltaic (Solar PV) power plants.

“Against the backdrop of global steel price increases over the last two years, it seems a safe bet that during the coming years precast concrete will play a major role in wind-tower construction,” concluded Coetzee.

Text: David Beer

CONTACT

Concrete Units

Montreal Dr, Airport Industria

Cape Town/South Africa

+27 21386 1923