Russia: State-of-the-art planning and production technology

The Morton construction and real estate group is breaking totally new ground in Russia: It is one of the first companies in Russia that are planning and constructing individual building projects instead of series buildings. The DSK Grad precast plant near Moscow is manufacturing the appropriate elements (see BFT International 08/2014, 07/2015, 08/2015). Prilhofer Consulting, who was commissioned with planning and design of the production equipment of the DSK Grad precast plant, together with the machinery and equipment suppliers involved, describe the project in this article.

The newly constructed DSK Grad precast plant has an internal design and planning office, developing their own projects in residential and social construction. A close relation of planning, production and construction within the manufacturing process minimizes the planning periods significantly. The elements are designed with the aid of state-of-the-art 3D modeling software, reducing the time required for the development of the elements and thus the overall project by a factor of 5.

Planning of conduits without clashes

The application of the single information space “Project Structure” allows planning of the different conduits for MEP without clashes. For planning the electrical parts embedded in the precast concrete elements, the design engineers use a BIM model for electric power supply. The architects plan cut-outs by means of an engineering model and pass on the specifications for the cut-outs to the design engineers. Afterwards, the shop drawings and the necessary specifications are prepared. Applying BIM at an early stage of the design process prevents a clash of the mounting parts. In addition, a catalog of embedded parts is available in order to minimize planning times. This catalog enables the engineers to generate element drawings automatically, including formwork drawings, insulation plans as well as positions of connection elements and reinforcement planning.

In the next step, the precast concrete element data is imported to the Allplan TIM - Technical Information Manager, for planning of the transport units. The prepared data are then transferred to the production, for creating the delivery schedule. The prepared UNI data are uploaded in a uniform system “1 C document circulation”, verifying their correctness in order to avoid any mistakes and errors in the production of the elements.

Following the necessary checks, the head designer releases the data for uploading; then they are transferred to the production of the products.

New standards in mixing

Prilhofer Consulting planned the production facility in close collaboration with Morton according to requirements of the buildings to be constructed. After an international invitation to tender, the contracts were awarded to companies throughout Europe and Russia.

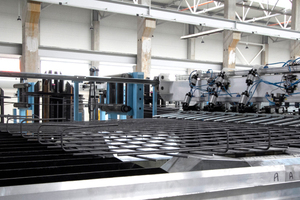

The production line is designed for manufacturing precast concrete elements for complete residential buildings, including complex sandwich façades. In addition, DSK Grad is manufacturing elevator shafts, ventilation shafts, staircases and balconies. As the production portfolio of Morton also comprises commercial buildings, the production line is also suitable for manufacturing of columns and prestresssed concrete beams as well as prestressed hollow-core floor slabs.

Teka Maschinenbau GmbH set new standards with the supply and installation of the concrete mixing plant: The entire mixing plant consists of five stand-alone and independent mixing stations situated next to each other. Four mixing stations are equipped with planetary mixers of type TPZ 3,750 with an output rate of 2.5 m³ per batch, one mixing station with a Teka high-performance Turbine Mixer THT 1,500 with a maximum output rate of 1.0 m³ per batch for the production of colored concrete.

The aggregates are taken up by two truck feed hoppers with a volume of about 20 m³ each. The belt conveyor with a length of more than 100 m is feeding the silo system. The silo system is divided in four rows with six compartments each, which makes 24 compartments in total. All compartments are heated and are controlled by temperature sensors.

A weighing conveyor with surge hopper is situated beneath each silo row. Eight binder silos featuring latest environmental and safety technology provide every mixing station with different binders through a total of 19 screw conveyors.

The concrete is supplied from the mixing plant to the different production lines by means of six skip conveyors of Dudik, simultaneously serving to transport the washing water of the concrete production process to the recycling plant.

Automatic production planning and logistics

Three pallet circulation systems of Sommer Anlagentechnik GmbH are used for the production of wall panels and floor slabs. The two circulation systems, used for the production of wall panels and floor slabs, have a capacity of 5.3 pallets per hour each. The circulation system, used for the production of sandwich elements, obtains a capacity of 2.9 pallets per hour. The SAA Engineering company implemented the entire process control of the three circulation systems. Every circulation system has an independent manufacturing execution system (MES); all three applications are installed together on a central server – in virtual environments.

The engineering department of Morton provides the production data in Allplan Precast. All relevant data for the ERP system are edited via the database interface. After importing the new data of the precast elements, production planning, i.e. the pallet configuration, is automatically conducted by the manufacturing execution system, creating a provisional production sequence – provisional because the shuttering robot also searches for and assigns an appropriate configuration depending on the side rail height of the pallet.

The manufacturing execution systems also provide for the entire logistics management. Examples are: timely production release for the mesh welding machine and retrieval of the wire meshes for automatic transfer by a wire mesh crane; timely request for delivery of concrete from the mixing plant in the required quantity and quality; determination of the transport routes for the pallets within the circulation system according to the work schedule – depending on the precast elements and the current plant utilization, the master computer decides which station is used next and at which time (e.g., formliner transfer, concreting unit, smoothing unit, formwork removal and lifting).

Insulation layer – easily and quickly installed

The shuttering robot of the sandwich production line automatically adjusts and independently changes the formwork height according to the requirements. The innovative waterjet cutting machine cuts the polystyrene boards used for the insulation layer to size, providing them stacked for every concrete element – for this purpose, the polystyrene boards are glued together resulting in only few wall-high elements. This simplifies and accelerates the manual installation onto the pallet and reduces the volume of waste considerably.

Textured formliners are used to design the façade of the sandwich elements. The formliner geometry has to be taken into account when automatically placing colored concrete for the external layer of the sandwich panels, in order to obtain the exact layer thickness so as to enable the installation of the facing boxes for the base layer. The supporting shell is compacted by internal spud vibrators attached to the concrete distributor, in an automated process.

It was soon possible to run the plants in normal operation due to the committed cooperation of the operating staff of DSK Grad – in case of any queries and failure the engineers of SAA are available for support at seven days of the week around the clock on the service hotline.

Innovative production line for sandwich elements

The companies Prilhofer Consulting, SAA, CSF and Sommer developed an innovative solution for the production line of sandwich elements (PU2). Textured formliners of Reckli create the respectively desired façade design in the formwork. For this purpose, the formliners are fixed to frames and are hold available in an automated "Power & Free" storage system of CSF – via an integrated interface the master computer is informed at any time which formliners are currently available in the storage area. The well-conceived control concept allows providing the production line with formliners in the right quantity, in the proper order and at precisely the right time. The formliners requested from the central unit are chosen from about 200 randomly stored parts.

Equipped with RFID transponders, each formliner can be clearly identified, thus the master computer is able to retrieve them from the storage system in an automated process. Thanks to the visualization software it is always possible to display the status handling as well as the location in the system.

The system consists of an active area for automatic retrieval and a passive area as "reserve stock" operated by an overhead crane. For assigning a pallet loading, the master computer checks whether all formliners are available in the active storage area, and only after this process the respective loading is released for production. At the same time, the master computer requests the necessary formliners from the storage system.

Sophisticated formliner sorting

A sophisticated sorting system (active storage area) always selects the fastest available formliners, which are then ordered and transported to the transfer station in bundles of four to six formliners. The master computer has provided the required formliners until the pallet has reached the installation station.

After lifting the elements at the tilting station, the formliners are also lifted and transferred to the storage system and an inspection station. The maintenance staff is automatically notified about the determined production cycles of the formliners. After inspection, the operator can either move the formliner out of the system for repair or put it in storage for reuse, by entering the respective confirmation in the control panel. Formliners which are not needed on a regular basis are stored in the so-called passive storage area.

Elevator and lowerator stations at the interface to the production line and to the passive storage area allow for transfer and lifting at an ergonomic working height. The operators use these stations, for example, to move formliners out to the passive storage area or new formliners into the active storage area; forms that are no longer needed or damaged are taken out of the system.

Special wire mesh made just in time

AWM has been awarded for the supply of all equipment for reinforcing mesh production and handling, as well as the logistic systems for 3D cage assembly and delivery to the three carousel plants and the stationary molds. All equipment has been installed on a mezzanine floor, above the carousel plants, this giving enough space to accommodate the machines and the materials used for the reinforcement preparation.

The project included the supply of n.3 high-speed automatic mesh welding lines model Flexiweld 3600 SW-SF, suitable to produce flat and bent meshes in large quantities. The mesh welding lines are equipped with multiple-wires bending units for the production of 3D elements and can manufacture special meshes just in time according to the production program. Once the meshes have been produced, they are automatically transported by means of motorized conveyors toward an assembly area where other motorized conveyors will facilitate the assembly of the reinforcement cages with the necessary inserts (lifting hooks, electric conduits, etc.). The aim of the motorized conveyor is also to create a buffer of meshes that will allow the mesh welding machine short stops for wire coil changes. Once the cages are completed a set of special cranes, also designed and provided by AWM, will hoist the product to the carousel system running underneath.

When no assembly is required (as in the case of the skin mesh for sandwich walls or in the case of the meshes used in the stationary molds area), an automatic crane will pick up the mesh from the welding machine’s exit bed and deliver it to the next step of the production process without going through the conveyors. An automatic mesh buffer was provided to store the flat meshes and grant a constant flow of reinforcement. A total number of 2 automatic cranes and 5 special cranes was included in the supply, while the total length of motorized conveyors sums up to almost 550 mt.

Beam molds and tilting tables for special elements

All modern construction systems are designed with the aim to ensure the modularity of the components and to optimize the utilization of the circulation system. However, even an optimized construction system does not work without special elements. Weckenman Anlagentechnik GmbH & Co KG was responsible for the field of special formwork in the project of DSK Grad.

Three tandem beam molds, featuring a length of 75 m each, for manufacturing prestressed but also untensioned concrete components in parallel, occupy already half of a hall bay. The beam molds are equipped with external vibrators and hydraulic system. As the side forms are segmented, it is possible to integrate the brackets at any position. The Weckenmann concrete spreader with turning and lifting unit is used for filling concrete in an optimum way. The hydraulic segmental slider allows an exact positioning of the concrete in the exact quantity. The tensioning equipment for the production of prestressed concrete beams was supplied by the German company Paul.

Four tilting tables with dimensions of 4.5 x 14 m each and side rails are available for the production of special elements, for which manufacturing on circulation systems is not cost-effective or even not possible owing to the overall size; they are equipped with vibrators and heating system in order to ensure an efficient production process. The concrete distributor of the beam molds is used for concrete feeding whose optimum features may also be fully exploited here.

Elevator shafts and balcony parapets

The adjacent hall bay is dominated by ten huge elevator shaft molds – five each for passenger and freight elevators. Shrinkable cores facilitate the removal of the finished elevator shafts and ensure the parallelism of the walls. Built-in vibrators provide for excellent surfaces and the heating for quick curing. The external forms can be moved and the core can be pulled back hydraulically, enabling better cleaning. The elevator shafts can be produced according to the respective floor height.

A battery mold is used for an efficient production of standard staircases. The well-known advantages of battery molds prove themselves in practice. For special staircases there is an additional formwork that can be adjusted in width or to the number of treads.

The balcony parapets are manufactured in two battery molds. They are designed similar to the battery mold for staircases with vibration device and heating, allowing additional adjusting the bottom of the formwork to the various parapet heights. It is possible to manufacture ten balcony parapets in angular shape with chamfered edge in parallel. A special feature of the mold is the possibility to insert textured formliners enabling various balcony designs. There are also two run-off systems with a loading capacity of 30 t each, which are specially equipped with gas engine to enable independent operation owing to the environmental conditions.

Automated production of hollow-core floor slabs

The hollow-core floor slabs are manufactured on a machine supplied by Elematic. The production of hollow-core floor slabs takes place in a complete hall bay on six 120-m long production lines.

For preparing the production lines a multifunctional device is used for cleaning and oiling of the beds as well as placing of the prestressing strands. The prestressing strands are pushed into the end supports; they are wedged in position and are prestressed by means of the single-strand stressing jack of Paul. After the preparation of the beds, concrete pouring can be started using the extruder.

For concrete discharge the bucket conveyor automatically finds the position of the concrete spreader, which runs along the production bed following the extruder and delivers the concrete into the extruder, in an automated process.

The configuration data of the casting beds are transmitted wireless through WLAN to a plotter of Elematic, that is plotting the cutting lines and other details onto the concreted hollow-core floor slabs, as soon as the concrete pouring process is finished. The machine operates automatically, positioning itself along the casting bed with the aid of laser distance measurement.

The finished elements are lifted from the bed by means of an adjustable lifting device, putting them in stacks onto a run-off system provided beside the bed. The run-off system of Elematic is transporting the finished stacks to the storage area. Using the automated Elematic production lines, DSK Grad is in the position to ensure a high production capacity and excellent product quality.

Efficient storage system

The storage area is designed so as to enable storing of the products from all production segments into all stockyard areas. The benefits of this concept are an optimum utilization of the storage area and that the routes of the storage area cranes are kept as short as possible.

The storage area comprises five crane bays which are occupied by two cranes each. The traffic concept developed by Prilhofer Consulting makes sure that the trucks take the shortest routes possible, without affecting each other. The arrangement of the cranes is already designed for rail loading as an option in future.

For the transport of flat elements, i.e. wall panels and floor slabs, the transport system of Faymonville is used. With the special transport vehicles, which are loading and unloading independently, so-called inloaders, the high level of traffic in the Moscow region is taken into account. The vehicles can provide the construction site with parts at times of light traffic, eliminating reloading on the construction site, which has been necessary so far. This is an essential contribution to an increased efficiency on the construction site.

CONTACT

Prilhofer Consulting GmbH & Co. KG

Münchener Str. 1

83395 Freilassing/Germany

+49 8654 69080

Bibko Umwelttechnik & Beratung GmbH

Steinbeisstraße 1–2

71717 Beilstein/Germany

+49 7062 92640

CSF Förderanlagen GmbH

Daimlerstraße 27

72644 Oberboihingen/Germany

+49 70 22 - 9 67 20

Elematic Oyj

Airolantie 2

37800 Akaa (Toijala)/Finland

+358 3 549511

Paul Maschinenfabrik GmbH & Co. KG

Max-Paul-Str. 1

88525 Dürmentingen/Germany

+49 7371 500-0

Reckli GmbH

Gewerkenstraße 9a

44628 Herne/Germany

+49 2323 1706 – 0

Teka Maschinenbau GmbH

In den Seewiesen 2

67480 Edenkoben/Germany

+49 6323 809-0

Walter Gerätebau GmbH

Neue Heimat 16

74343 Sachsenheim-Ochsenbach/Germany

+49 7046 980-0

http://walter-cleaningsystems.de

Weckenmann Anlagentechnik GmbH & Co. KG

Birkenstraße 1

72358 Dormettingen/Germany

+49 7427 9493-0

Würschum GmbH

Hedelfinger Straße 33

73760 Ostfildern/Germany

+49 711 44813-0