Welding line PLR Truss and Series PLT B Ladder

In addition to our wide offer of welding machines for the production of standard mesh, customized and special mesh, Eurobend GmbH offers a full range of automatic welding machines for the fabrication of wall reinforcements, spacer and bar support baskets.

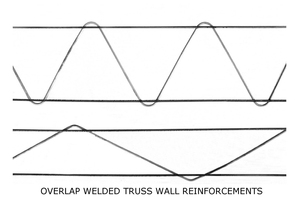

Welding machines of the PLR Truss series have a simple machine layout for the reliable and cost-efficient production of wall reinforcements of sandwich walls. The machine can be supplied with “T” type or overlap “R” type welding heads. The servo-motor driven bending device ensures fast and accurate size changeovers and excellent repeatability. Powered de-coiling stations for line and diagonal wires with frequency inverter control and tension detector ensure smooth feeding of wires.

The newest PLR Truss of Eurobend is equipped with a fully automatic bundling and strapping station.

PL Truss welding machines are located in companies in the USA, Denmark, Russia, UAE, China, among others. The PLR Truss belongs to the Eurobend family of machines that produces all common types and sizes of wall reinforcement elements and is - according to the supplier - the only machine on the market that allows a variable diagonal wire step. It has:

Servo drive;

Minimal requirements and changeover times for product changes;

Quickly changeable straightening systems that cover a wide range of wire diameters and allow quick, accurate diameter changes;

A bending system that guarantees high repeatability;

A line wire spacing guide system that allows automatic product width changes in less than 2 minutes;

A user friendly software that requires no programming knowledge;

Fully automatic bundling and strapping station.

Eurobend also offers welding equipment for all types of spacers for bar support and mesh.

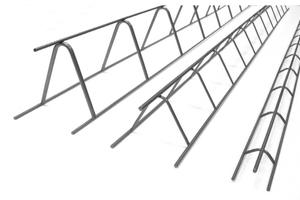

Series PLT B Ladder for the production of ladder type strip spacers (snake spacers)

The PL B Ladder welding machines have a simple lay out and ensure reliable and cost-efficient, fully automatic production of trapezoidal or S-shaped Spacers from coil. The spacers are produced in longitudinal direction. They are available with either „T“ (butt) or „R“ (overlap) welding heads. The sophisticated design allows minimal changeover times for the various product heights. The machines are also offered with an integrated, fully automatic stacking and strapping system. In the case of the butt-welded elements produced with the PLT B Ladder models, the large material savings and optimal, compact bundling, contribute to significant production cost reductions. In addition, the butt welding eliminates the need to turn the elements.

The operator only has to monitor the production process from time to time and remove the automatically finished bundles.

PLT B Ladder welding machines from Eurobend can be found in companies in Germany, Poland, the Czech Republic, the USA and Brazil, among others.

Series PLT B Spacer and PLR B Spacer for A baskets

All types of A-baskets can be produced on the PLT B Spacer and PLR B Spacer machines. Models with simultaneous feeding of 6 cross wires, can produce an element in under 4 seconds. Models are available for elements with „T“ (butt) or „R“ (overlapping) welding heads.

The final product is stacked fully automatically. Each stack is automatically lowered onto a table at working height for convenient removal.

PLT B Ladder welding machines from Eurobend can be found in companies in Germany, Poland, the Czech Republic, the USA and Brazil, among others.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980