New welding machine for Pretec Denmark

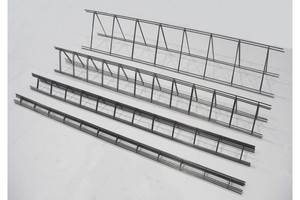

In addition to the offered broad range of welding lines for the production of standard and specialized construction mesh, engineering, precast or architectural mesh, Eurobend GmbH offers a full range of automatic welding machines for the production of all types of bar spacers/supports, wall ties/girders and similar products. The latest installation of a PLR Truss welding line took place in Køge, Denmark for the customer Pretec. Pretec has a strong presence in Denmark as well as in Sweden, Finland and Norway, supplying precast companies with a large selection of products, inclusive of their truss wall-ties for sandwich walls, which will be produced by their new PLR Truss welding machine. This latest machine version of Eurobend’s PLR Truss is equipped also with a fully automatic bundling and strapping unit.

The PLR Truss – welding lines have simple machine layout and ensure a reliable and cost-effective production of truss wall ties for sandwich walls. The machine can be supplied with overlap “R” type welding heads or optionally with “T” type (machine version PLT Truss) welding heads. A fully programmable servo-motor driven diagonal wire bending device ensures accuracies, repeatability and fast product size changeovers. The powered de-coiling stations for line and diagonal wires with frequency inverter control and wire tension detector ensure smooth feeding of wires.

PL Truss welding machines

PL Truss welding machines are installed, among others, in the USA, Denmark, Russia, Dubai, V. R. China etc. The PLR Truss welding machine belongs to a family of machines offered by Eurobend producing all common types and sizes of wall ties and is the only machine in the market, which offers a variable diagonal wire step. It has the following features:

Servo-driven operation;

Minimal changeover requirements;

Fast & accurate diameter changeovers thanks to quick set-up straightening systems, covering a broad range of wire diameters;

Bending system, which ensures very high repeatability;

Line wire guide system for product width changes in less than 2 minutes;

User friendly software, which requires no programming skills;

Fully automatic, synchronized stacking and strapping system;

Operator is only required to supervise from time to time the production process and remove the automatically produced bundles.

Eurobend offers also welding machines for the production of lattice girders:

PL Tris lattice girder series

The PL Tris series of lattice girder welding lines can produce most types and sizes of lattice girders and offer reliable and cost-effective production.

Powered de-coiling stations for line and diagonal wires with tension detector, or wire loop accumulators, according to machine version, ensure smooth and accurate feeding of wires. Straightening section employs patented product self-leveling anti-twist rollers.

Different models are available for both the economic and high output production of lattice girders.

The continuous bending system, for double and quad step lines, with retractable bending pins for the two diagonal wires, ensures accurate and consistent operation.

The PL Tris machines have flexible welding heads with electrically driven height adjustment for the production of various lattice girder sizes. Hydraulic clamping units, mounted on a servomotor driven carrier, ensure accurate feeding of wires and lattice girders. High speed cutting operation ensures continuous lattice girder production. Automatic and fully automatic, synchronized stacking and batch removal modules are available.

Eurobend’s PL Tris welding lines are used by companies in Netherlands, K.S.A, S. America, etc.

Eurobend offers also welding machines for the production of all types of wire spacers and bar supports:

PLT B Ladder and PLR B Ladder series for snake spacers

The PL B Ladder welding machines have a simple layout and offer reliable and cost-effective production of S shaped or trapezoid shaped snake spacers from coils. The spacers are produced in longitudinal direction. Available with either “T” type or “R” type overlap welding heads. The sophisticated design allows minimal changeover times for the various product sizes. The machines are offered also with a fully automatic, synchronized stacking and strapping system. The great material savings and the optimal, compact bundling of the “T” welded spacers produced by the PLT B Ladder machines, result in significant production and transport costs reductions. The “T” welding makes a turning of the elements for stacking unnecessary.

The operator is only required to supervise from time to time the production process and remove the automatically produced bundles.

PLT B Ladder welding machines are installed, among others, in the USA, Germany, Poland, Brazil.

PLT B Spacer and PLR B Spacer series for A- shaped supports

All types of A- shaped supports can be produced on the PLT B Spacer and PLR B Spacer machines. In machine versions with simultaneous feeding of six cross wires one complete element can be produced in less than 4 seconds. Models available with either “T” type or “R” type overlap welding heads. The elements are stacked fully automatically into bundles. Each bundle is placed automatically on a table at a working height for convenient removal.