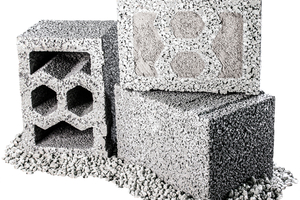

Bionic block with purely mineral foam filling

Load-bearing capacity and likewise high thermal insulation need not be mutually exclusive. This is proven by the new „KLB Wabenstein“ hollow block of the renowned lightweight concrete manufacturer KLB Klimaleichtblock (Andernach, Rhineland-Palatinate): With its bionic internal structure and integrated insulation filling made of purely mineral foam, the lightweight concrete block is a novelty in the market and yields top results in the fields of structural stability, sound insulation and thermal insulation. Especially for filling the block, an energy-efficient and low-maintenance plant was erected, that represents a technical highlight in the production of solid wall building materials across Germany. The development of this building material that is unique in the masonry industry was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi, Berlin) as well as the Rhineland-Palatinate Investment and Structural Bank (ISB, Mainz).

For almost five decades, the Andernach-based supplier of lightweight concrete – KLB Klimaleichtblock – has constantly set new standards in masonry construction, that quite often have proven to be trend-setting: These range from the investigation and early market launch of masonry blocks with integrated insulation to today‘s development of large-sized KLB Quadro block units or the KLB Ratiowall wall panel system. Now, the KLB Wabenstein hollow block complements the range as latest innovation and highlight in terms of production technology: It has a bionic internal structure, providing the block with a particular strength. Its insulation filling made of purely mineral foam is filled in in a plant that is especially designed for this purpose. Owing to its characteristics, the KLB Wabenstein achieves top results in terms of structural stability, sound and thermal insulation, thus being one of the most efficient thermal-insulating exterior wall blocks being manufactured of lightweight concrete at present.

Geometry rethought

Nature often sets a pattern for research and science. Hence, the field of bionics, for example, deals with making biological phenomena applicable for technological developments. The KLB Wabenstein hollow block is based exactly on this approach of research because its bionic internal structure is inspired by the natural shape of a honeycomb. This structure improves the strength and stiffness of the block, achieving a reduced natural vibration and, as a consequence, high sound insulation of the exterior walls with a direct sound reduction index Rw,Bau,ref of minimum 48 dB (strength class 2) up to over 50 dB (strength class 4).

The filled mineral foam based on mortar that is made by Sika (Baar, Switzerland) also contributes here: It consists of 95 % entrapped air, making the hollow block not only highly thermal insulating, but also particularly sound insulating. Since own recycled material can be used for the foam production, it is an extremely resource-friendly and sustainable insulation solution, too.

Ultra-modern and perfectly matching

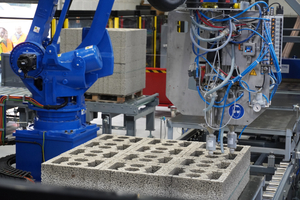

An energy-efficient and low-maintenance plant was designed especially for the filling material of the lightweight concrete block. The plant is operated by Trasswerke Meurin (Kretz, Rhineland-Palatinate), which become part of KLB Klimaleichtblock GmbH as new company member on January 1, 2025. Whereas Gertec Maschinen- und Anlagenbau GmbH (Sulzberg) developed a highly complex two phase mixing system for the plant, Antriebstechnik Saftig GmbH (Plaidt, Rhineland-Palatinate) was responsible for the development of a 4-axis robot meant for fully automated filling and palletizing.

In this process, at first, the insulating material is introduced in a liquid state into the cavities of the 249mm-high block units to about one quarter, for subsequently expanding and setting within 30 minutes – without any energy supply. Excess foam can be removed and is returned into the production. In a final step, the robot turns the KLB Wabenstein hollow blocks by 180 degrees and loads them on pallets. The KLB Wabenstein hollow block is the outcome of a joint project that was promoted by research funds of the Federal Ministry for Economic Affairs and Energy (BMWi, Berlin) and the Investment and Structural Bank of Rhineland-Palatinate (ISB, Mainz).

As an innovative high-performance product, the KLB Wabenstein hollow block above all is suitable for the construction of thermally insulating exterior walls being open to diffusion, not requiring any external insulation additionally (EIFS).

100 % mineral and recyclable

Like its predecessors at KLB, that are filled with mineral insulating material, it follows the approach of an internal separation of functions: In this regard, solid webs made of properly washed pumice assume the structural tasks, while the high-tech insulating foam based on mortar significantly ensures the thermal insulation. This provides for the excellent values of up to 0.08 W/mK so that current standards regarding the construction of government subsidized energy-efficient houses will be met easily.

The KLB Wabenstein hollow block is available in common block widths of 36.5 cm and 42.5 cm, with obtaining the strength classes 2 and 4. Moreover, the block has passed the firewall test successfully, therefore the classification up to the suitability as firewall has been applied for.

Due to its purely mineral nature, the KLB Wabenstein hollow block can be fully recycled and returned to the production cycle. Besides the low-energy production, this is another plus in the outstanding life cycle assessment of the new building material made of lightweight concrete.

CONTACT

KLB Klimaleichtblock GmbH

Lohmannstraße 31

56626 Andernach/Germany

Andreas Krechting

+49 2632 2577-0