CO2 footprint as viewed by the precaster Kirchdorfer

Kirchdorfer Concrete Solutions, and thus the subsidiary of MABA Fertigteilindustrie, has made it its objective to produce, by 2030, more “climate fit.” In order to achieve the defined sustainability objective Beton30 (concrete to the power of 30), recycling of aggregate by 30 % and reduction of binders and during transport by 30 % by 2020, a comprehensive approach to climate-neutral and energy-efficient management is needed.

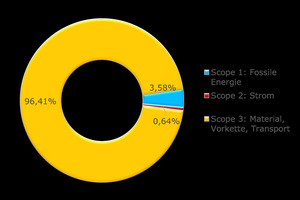

The breakthrough in strategy was found by formulating the 30³ vision. The number 30 shows a challenging direction for all corporate areas. It is important to make the vision-concept tangible to all stakeholders. Kirchdorfer Concrete Solutions, together with external support, defined suitable parameters for visualization of all CO2 emissions and rucksacks in the form of CCF (Corporate Carbon Footprint) and PCF (Product Carbon Footprint). In the first step, the Corporate Carbon Footprint (CCF) was analyzed at the MABA plant in Wöllersdorf in Austria, based on the entire business activities over a period of one year. For this step, scopes 1 & 2 (energy & heat requirement, company cars) and/or 3 (CO2 rucksacks of raw materials and embedded parts) were visualized and the Product Carbon Footprint (PCF) calculated for the comprehensive product portfolio.

Keeping the rucksack as small as possible

“We quickly realized that software was needed that would supply accurate data on materials, components and processes. In collaboration with DI Dr. Christian Plas (Denkstatt.at) we programmed a unique tool with the aid of which the PCF for thousands of MABA by-products can be precisely quantified,” explains Dipl.-Ing. (FH) Franz Buschmüller, Managing Director of MABA Fertigteilindustrie GmbH and CTO of Kirchdorfer Concrete Solutions. This enables Kirchdorfer Concrete Solutions to evaluate the production plants separately from the precast products and to efficiently and effectively improve all areas.

For this step, Buschmüller formulated as follows the primary objective of keeping the rucksack as small as possible: “Our survey found that a total of 94 % of CO2 input into MABA-Fertigteilindustrie results from a rucksack that is so to speak delivered to our plant through the use of concrete, and here in particular in the form of binders and the required reinforcing steel.” A successful reduction of the CO2 rucksack thus begins with product development, continues to the use of reinforcement and the choice of concrete formulas and ends with production and transport processes. Challenging goals can be achieved only by taking this interlinked point of view and the corresponding data quality.

First railroad sleeper pilot project started

Last year, a first pilot project for railroad sleepers was started in collaboration with ÖBB-Infrastruktur AG and the concrete technology experts of Austrian Railroads. Here success was achieved in reducing CO2 emission by nearly 30 % for production of the L2 sleeper by adjusting the formulas. At the beginning of 2023, all the concrete test results were already available. Kirchdorfer Concrete Solutions was especially proud of introducing the following measures:

Preparation, quality control and approval of recycled concrete (a baseline study conducted jointly with Smart Minerals/TU Vienna);

Use of recycled concrete for noise protection applications;

Optimization of self-compacting concrete formulas by applying artificial intelligence;

Efficient energy supply by the MABA production locations in Wöllersdorf, Sollenau, Gerasdorf and Micheldorf in Austria, with made-to-measure photovoltaic systems.

The added-value chain was oriented according to ecological criteria based on the analysis of a detailed CO2 footprint for all product groups and all production plants. On this basis, precast products with lower CO2 content from Kirchdorfer are delivered to the customer.

CONTACT

Kirchdorfer Industries GmbH

Hofmannstraße 4

4560 Kirchdorf/Austria

+43 57715100-0