Five competencies in precast element production under one roof

MABA Fertigteilindustrie GmbH was founded in 1924 and can thus look back on almost 100 years of company history. The company manufactures prefabricated concrete components of outstanding quality. MABA, growth oriented now as before, quickly identifies technological trends and develops innovative concrete products.

MABA Fertigteilindustrie GmbH was founded 1924 and can thus look back on almost 100 years of company history. In the course of time, the Austrian predecessor company, Österr. MABA-Unternehmung – Bartels und Schlarbaum, evolved into a highly regarded manufacturer of prefabricated concrete components. The company has manufactured to this day a defined product range of outstanding quality, based on field-tested experience. Now as before growth oriented, MABA Fertigteilindustrie GmbH quickly identifies technological trends and develops innovative concrete products.

Today – 99 years after the company was founded – a workforce of approx. 500 generate on four locations an annual turnover around €100 million.

In addition to the company headquarters in Wöllersdorf, MABA, part of Kirchdorfer Concrete Solutions, produces at the locations Gerasdorf, Micheldorf and Sollenau.

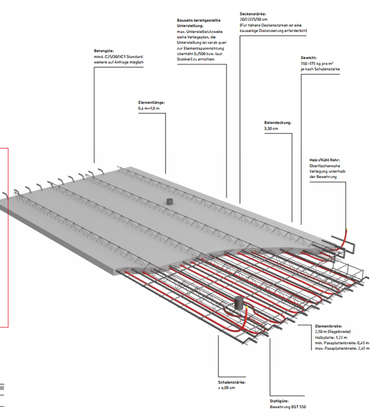

MABA combines five competences under one roof: in Gerasdorf, a workforce of almost 130 manufactures in three shifts element floors, double walls, cage walls and composite XC floors. Additional products from MABA are concrete products for building & industrial construction (system building elements from basement to roof for residential and commercial construction), civil engineering (manhole components, foundations, masts, embankment stabilization etc.), roads (concrete components for traffic safety, noise protection and drainage systems) , railway construction (railway sleepers, masts) as well as precast concrete elements for tunnels and a range of special solutions: e.g., fish bypass systems and movebloc loading systems for bicycles.

Modernization while working at full capacity

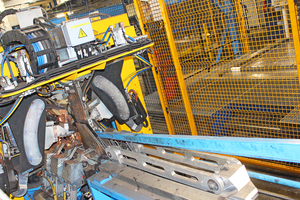

In the spring of 2022, the MABA plant in Gerasdorf was considerably modernized while working at full capacity. With the new state-of-the-art plant and equipment, productivity at the already highly automated location was further increased.

With additional shifts and a young, highly motivated production manager who give it their all with great commitment in Gerasdorf, MABA was able to partly maintain production during the three-months conversion phase in Hall 3, where cage and parallel walls are now produced in parallel.

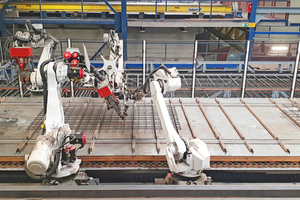

The conversion was implemented according to plan under the lead management of DI (FH) Gernot Koisser, MBA (Project Manager), Ing. Jürgen Strohschneider (Site Manager) and DI (FH) Markus Giefing (Production Manager). Optimization of production layout, use of an additional shuttering robot and shorter cycle time achieved a significant increase in production capacity. The old mesh-welding plant from 1995 was retired, and in-house lattice-girder production boosted the location’s added value. Toward the end of the conversion phase, Jürgen Strohschneider took over management of the Gerasdorf location and thereby returned after six years in Wöllersdorf to his home plant in Wöllersdorf.

As early as 2019, Hall 3 at the Gerasdorf location underwent development into a Competence Center for Wall Production. The competitiveness of the location was strengthened after comprehensive conversion and/or exchange of plant and equipment, of the hall and of the control systems – while at the same time lowering costs. This was achieved with goal-oriented and timely investments based on a future-oriented layout and sequencing schedule for a project with several construction phases, and with the capability of carrying on with production. Special attention was paid to maximum technical upgrading of the plant, a high safety standard and economically sustainable implementation. The objective had been to cover the entire wall production capacities of the two existing wall production systems with the newly converted Hall 3.

Actual conversion measures in Phase 1 (Jan 2020 to Mar 2021) were implemented by the Leyer+Graf Baugesellschaft. Production engineering was provided by Vollert Anlagenbau and Sommer Anlagentechnik.

Phase 2 (Jan 2021 to Mar 2022) was implemented with participation of the companies Vollert, Sommer, RIB SAA Software Engineering, EVG and Progress Maschinen & Automation. Reinforcement measures on the floor above the ground floor were carried out by Unger Stahlbau. The greatest challenge here was integration of the new equipment and systems in the already existing pallet rotation system. Because conversion took place while producing to full capacity, any capacity deficiencies were cushioned by the other production halls on the location.

Production Manager Markus Giefing explained: “We decided on the mentioned suppliers because in the past we had positive experience with them, and partly because of special requirements – owing to the plant concept – special solutions were required.”

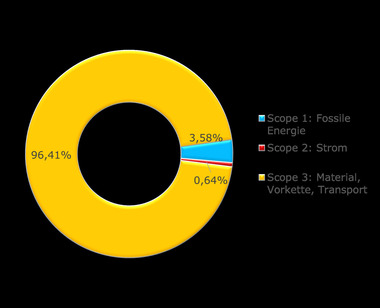

CO2 footprint to be improved

“We develop sustainable precast concrete elements,” explained MABA’s managing director Franz Buschmüller. “We are constantly reducing our CO2 footprint with various measures. For example, we are constantly optimising all concrete recipes.”

Site manager Jürgen Strohschneider adds: “Furthermore, we were anxious to update the “precast concrete technician” as an apprenticeship. This was successfully implemented in cooperation with the VÖB (Association of Austrian Concrete and Precast Plants) with the aim of raising the apprenticeship profession to a contemporary and attractive level.”

Dr. Thomas Kranzler, Managing Director of the Syspro-Gruppe Betonbauteile and initiator of our visit, was visibly impressed. “MABA, as the Austrian member of the Syspro Group, brings new initiative and perspectives into the Group, from which our other members in Germany, Belgium and Italy can also profit. For the BFT editorial office and myself, who have already seen many precast plants from the inside, modernization of production with this magnitude – while working at full capacity – is truly exceptional. Therefore, we would also like to take this opportunity to say a big thank you to MABA for inviting us – and to extend my congratulations for successful modernization.”

CONTACT

Maba Fertigteilindustrie GmbH

Kirchdorfer Platz 1

2752 Wöllersdorf/Austria

+43 5 7715 400

Syspro-Gruppe Betonbauteile e. V.

Matthias-Grünewald-Str. 1-3

53175 Bonn/Germany

+49 228 37756322

Der Aufstieg der MABA

Meilensteine des Betonfertigteilherstellers

Der Ruf des Abenteuers

Gründung 1924: Martin Bartels und die Gebrüder Schlarbaum wagen sich in die neue Welt der Betonwaren.

Die Herausforderung

In den Jahren 1954-1972 wächst die MABA und stellt sich den Herausforderungen des Fertigteilmarktes. Die Erfolgsstory aus Stahlbeton und Sonderbauteilen beginnt.

Die Wandlung

Der Eigentümerwechsel der MABA zur Kirchdorfer Gruppe im Jahr 1984 war ein Wendepunkt. Die MABA muss sich neu ausrichten, um zukunftsfähig zu bleiben. Produkte werden erweitert und optimiert.

Der Aufstieg

Ab 1985 tun sich neue Chancen auf, die Produktpalette wurde u.a. um Deltabloc und Ziegelit erweitert. Mit Fusionen, Neugründungen und Expansionen ergreift man neue Chancen.

Die Produktvielfalt

In den Jahren 2010-2015 entwickelt sich MABA weiter. Neben hoher Kundenorientierung setzt man auf innovative Produkte bei Schallschutz (Lärmschutzelemente) und Umwelttechnik (Fischaufstiegshilfen, Entwässerungsysteme).

Die neue Stärke

Eine neue Konzernstruktur schafft die Grundlage für weiteres Wachstum. Die Sparte Kirchdorfer Concrete Solutions ebnet den Weg für Joint-Ventures, starke Partnerschaften & neue Märkte.

Der Ruf der Zukunft

Heute zählt die MABA zu den größten Betonfertigteilherstellern Österreichs und steht für Qualität, Innovation & Umwelteffizienz.

Bausteine der Modernisierung:

Neu: Wendestation; Palettenwendegerät; Fa. Vollert: Zykluszeit im Automatikmodus: <= 10 min.

Neu: Schalungspaletten Fa. Vollert

Neu: Schalungsroboter mit Passivmagazin, Schalungsreiniger; inkl. Setzen von E-Dosen Magnete (Firma Sommer, Anlagentechnik / Firma SAA, Steuerung/SW)

Neu: Schalungsprofile (Lock System) von der Fa. Sommer

Neu: Mattenschweißanlage mit Puffer inkl. Mattenhandling vom Obergeschoss in das Erdgeschoss

Neu: Gitterträgerschweißanlage Fa. Progress mit Puffer

Neu: Umlauferweiterung Fa. Vollert inkl. Palettenreinigung

Neu: Umlaufsteuerung Fa. SAA

Umbau: Bestands-Schalungsroboter in einen Entschalungsroboter -> Fa. Sommer (Firma Sommer, Anlagentechnik / Firma SAA, SW)

Umbau Halle: Hallenverstärkung Decke über EG -> Fa. Unger Stahlbau