Concrete production at Plötner modernized to increase efficiency and optimize quality

Betonwerk Carl Plötner GmbH, a renowned supplier for high-quality concrete products, has further increased the efficiency and quality of its concrete mixing plants. For the modernization of the face concrete mixing line at the Plaidt factory, Plötner relied on the expertise of Eirich in order to optimize the production process and to reduce the reject rate. Due to the introduction of a new face concrete mixer, the concrete plant could not only improve the product quality, but also reduce downtimes and cleaning efforts considerably.

The production of concrete products requires highest precision when processing a batch. High reject rates and inefficient cleaning processes restricted the production capacities and the productivity at Plötner. The modernization was aiming at enhancing the mixing quality, improving the homogeneity of the mixture, and minimizing machine downtimes. In addition, the effort of cleaning the block making machine should be reduced because the face mix concrete often adhered to the tamper plates, thus causing production losses and/or unintended interruptions of ongoing operations.

State-of-the-art face concrete mixer for optimized processes

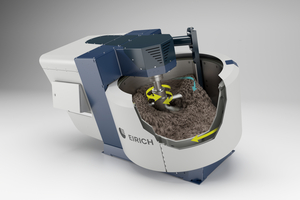

Eirich has modernized the mixing line in an existing plant: Along with the face concrete mixer of type RV12 500, the existing plant equipment (weighing unit, skip hoist, batching, and weighing platform, etc.) was adapted accordingly. The face concrete mixing line is provided with a new powerful dust extraction system and a PU cover for the product transfer. Apart from the installation of the technical components, Eirich also assumed engineering and performance check of the plant.

Improved mixing results:

Improved distribution of moisture: Significantly less tamper adhesion, which reduces machine downtimes and the cleaning effort considerably;

Consistent coloration: The uniform distribution of the cement and pigments provides for a brilliant and consistent coloring of the products;

Efficient cement preparation: Cement is better disintegrated and incorporated into the mixture, resulting in a higher quality of the final products;

Reduction of the reject rate: The high homogeneity with uniform moisture and a constant quality of the mixture led to a drastic reduction of rejects and consequently lower disposal costs.

„Modernizations within existing plant equipment always involve certain challenges which we could master together thanks to close coordination with Plötner. It is important for us to use and supplement existing components so that not only the direct mixing result is optimized, but also the entire process up to the final product,“ explains Stefan Berberich, project engineer at Eirich.

Course of the project: Close coordination and implementation on schedule

The project started in October 2022 with the initial contact at the bauma trade fair. Following the detailed planning and discussions on site as well as the elaboration of the conversion plans, Eirich was awarded with the contract for the modernization in December 2022. The conversion of the plant was realized in close coordination with Plötner. The installation of the new plant components and the performance check ran smoothly so that the modernized mixing line could be put into operation in March 2024.

Significant increases in efficiency and high customer satisfaction

Thanks to the modernization, the Plötner concrete plant could achieve significant improvements in the production, thus being best prepared for future requirements. Christoph Plötner, the general manager of the company, enthusiastically declared: „We hardly have any rejects and were able to reduce our cleaning cycles by half. When replacing further mixers, Eirich mixers will certainly be on the short list.“

The project at Plötner clearly shows how the use of modern mixing technology in combination with close coordination with the customer can result in substantial improvements in efficiency and quality.

CONTACT

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Walldürner Str. 50

74736 Hardheim/Germany

+49 6283 510