Concrete products manufacturer Rünz und Hoffend invests in the new Qaver-Darrer combination

The company Rünz und Hoffend was founded in 1925 in the German state of Rhineland-Palatinate and is today a successful medium-sized building and garden and landscape construction company. With the slogan “Designing with stone,” the company offers an extensive range of services in the garden and landscape construction sector. This includes the design of pavement areas, patio slabs, dry stone walls, palisades and shuttering blocks – always with focus on the individual wishes of the customers. Rünz und Hoffend has successfully navigated the transition to a high-tech concrete plant and has digitized its in-company quality control with Qavertec test equipment – and has raised it to a new level.

Controlling the quality of freshly produced concrete products is in concrete plants often a manual task and, accordingly, is fraught with inadequacies. Because quality control depends to a great extent on the experience and attention of the responsible staff, it is accordingly based on subjective assessment. In addition to test parameters such as appearance, height and weight, other factors are involved: e.g., the w/c ratio and compaction, which cannot or can only imprecisely be determined without technological equipment. These imprecisions can lead to defects that will only later become apparent and may lead to claims. Incomplete and inconsistently written documentation unfortunately provides little information, and transparent tracking of quality and the production process – as well as subsequent analyses – are virtually impossible.

Concrete is, moreover, a material with properties influenced by many factors, among them raw materials, mixing ratios, water temperature, processing temperature and even air humidity. Since these variables can frequently change, manual quality control means that uniform high quality cannot always be attained. To meet these challenges, the company Rünz und Hoffend pursues the objective of linking up and comparing data from plant production with quality data, with the goal of obtaining the maximum possible consistency of product quality.

Combination of Qaver and Darrer convincing

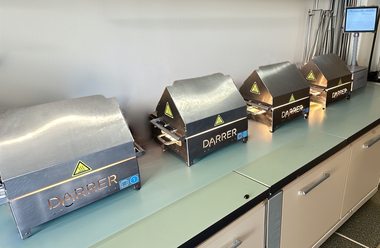

In March 2023, Hugo Kessler, Managing Director of Rünz und Hoffend, read in a newspaper article about the Darrer system and consequently about the Qaver. The innovative combination of Qaver and Darrer convinced him, and he decided to consequently invest in the purchase of a Qaver, i.e., the model Qaverlight, including a special manual attachment, and a Darrer. With this recent investment, Rünz und Hoffend further optimized its production technology and simplified its quality control through digitization – and, in this way, detached its production from subjective assessment. The investment moreover enabled the company to produce concrete even more sustainably and, at the same time, to ensure high quality. In addition, it prevents waste, due to insufficient compaction and porosity.

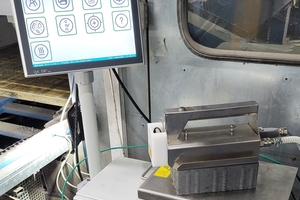

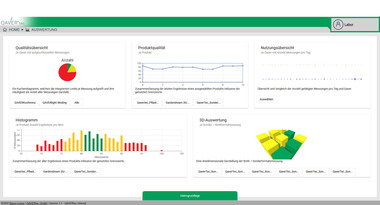

With the Qaver patented test and documentation unit, the properties of freshly produced concrete can be controlled, documented and continuously improved. In addition to height and weight, the Qaver system also determines face and core compaction, independent of each other, as well as total raw density: which enables detailed quality analysis. During the measuring process, the time of measurement, the measured results, the predetermined specifications, any deviations from the target value as well as the name of the responsible person are documented. These data can be viewed either directly on the equipment or, at any time, in the online evaluation tool.

The advantages of the Qaver system include person-independent reproducible results directly at the work site, which enables cross-plant comparability of data for efficient quality assurance and exclusion of transition errors by precise digital measurement methods. The Darrer is a state-of-the-art solution for precise checking of the net water content of concrete and/or mineral aggregate. The system comprises a station – in this case, the Qaver – and the Unit, which enable quick and precise moisture determination by evaporation and can be used for weights of up to 2.0 kg per cycle. By combining Darrer and Qaver, it is now possible to add the w/c ratio to data collection for quality control. This comprehensive documentation and the innovative functions of the Qaver-Darrer system critically contribute to quality assurance and optimization of the production processes.

Enthusiastic machine operators

The system offers product management that allows individually adjustable settings for the weighing and measuring processes. Evaluation of the measured results takes place by special software that enables simple and user-friendly analysis. In addition, the results can be prepared in the form of PDF protocols that can be forwarded either by USB or a network resource to simplify further processing and archiving of data.

The Qaver-Darrer system has now been in operation at Rünz und Hoffend for three months. The operators of the machine are especially enthusiastic about the simple operation of the system. The digital quality control features have already eliminated several tons of waste and have enabled partial optimization of formulas. In other words: the investment is a resounding success and for R und H a further important step on the way to a state-of-the-art, digitally controlled concrete plant.

CONTACT

Rünz & Hoffend GmbH & Co.KG

Gewerbegebiet Brückenstraße

56220 Urmitz/Germany

+49 2630 8001-0

Qavertec GmbH

Heideland 20

24976 Handewitt/Germany

+49 461 70 71 78 40