Qavertec develops innovative measuring and documentation systems

In the meantime, the Omnicon Group has become one of the leading system providers for products used for coloring and optimizing of concrete products. Smart solutions, sophisticated concepts and know-how – as a well-established partner of the construction and concrete industries, the portfolio of the Omnicon Group is synonymous with high standards, according to the company‘s own information. The product range includes colors for concrete, additives, surface protection and quality testing devices as well as services in the fields of recipe optimization, process and application technology as well as the production of pastes, coatings and surface protection systems. Today, the four companies Omnicon, Qavertec, BKS and OTE are members of the group.

„We are constantly working on new solutions so as to support our customers to be able to offer the optimum product and to satisfy the growing requirements of the market,“ states Omnicon‘s General Manager Thorsten Biallas.

Concrete products are real all-rounders, and in addition to functional aspects, they also need to meet the high expectations in respect of cleanability and freedom from efflorescence along with durable aesthetics. The basis for this is built by a high and consistent quality of the concrete product. Therefore, a transparent and consequent quality control conducted in the concrete plant is essential and the objective of the innovations made by Qavertec.

Qavertec innovative part of the Omnicon Group

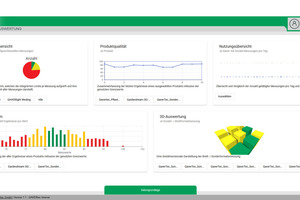

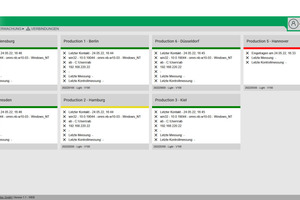

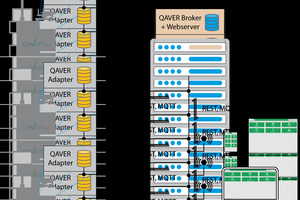

The Qaver patented testing device is the core component of quality control in the concrete plant, providing the following options: It allows determining the compaction quality of the face and core concrete immediately after the compaction process of a freshly manufactured concrete product, measuring the height and the weight for evaluating the density. The incorporation of Qaver into the company‘s own network in combination with the use of the new software program - „AWP 2.0“ - enables the management of products independently of location and the documentation of all measured results of the individual Qaver devices virtually in real time for later evaluation.

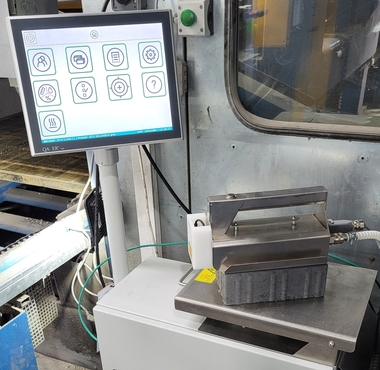

Kann GmbH Baustoffwerke located in Bendorf has recognized for its company the possibility to coordinate Qaver via AWP 2.0 centrally and to gather the measured results, thus having integrated most of the production sites meanwhile. Just a few clicks allow for a direct comparison of the quality of individual products, machines or entire production lines of the different locations. With the Darrer, Qavertec will present a new testing device for the determination of the water content of fresh concrete and aggregates at Bauma. The technique of drying, namely determining the net water content by means of the mass loss when drying a mass, basically is not unknown. But what is new is the fact that the Darrer has been developed for the requirements of the concrete industry in particular. Thus, it is possible to determine the moisture of fresh concrete or corresponding mineral aggregates weighing up to 1.5 kg per run. The process can be started directly or through a stored recipe. Then, the final result is assigned to the respective recipe and stored. This saves time in documentation and reduces the error rate in comparison to standard methods such as using a microwave or heating the mass with the aid of a gas stove, for example. The centerpiece of the Darrer control system is a full-featured industrial computer with a Windows 10 IoT operating system, which therefore can be integrated in modern company networks and can be co-administered via the new AWP 2.0 program. It is possible to connect up to four Darrer stations to a PC unit and to operate them in parallel.

In addition, it is planned to connect the Darrer with the latest generation of the Qaverbase so that it can operate the Darrer at the production line directly as well.

Only those who recognize details are able to improve the quality

„Only who knows all details can control its quality and is ideally equipped to save resources and to optimize the production process,“ states Sönke Hanse, General Manager at Qavertec and Sales Manager of the Omnicon Group.

Those who want to experience the innovations of the Omnicon Group at first hand and would like to be advised by specialists, should put the Bauma held in Munich from 24th to 30th October on the agenda. „We will be present there with numerous innovations and will be pleased to answer your questions,“ Thorsten Biallas invites.