Connecting device for fabricated concrete frame and prefabricated wall panel

(10) CN117567059

(22) 23.02.2024

(43) 29.03.2024

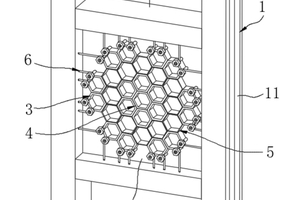

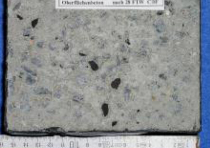

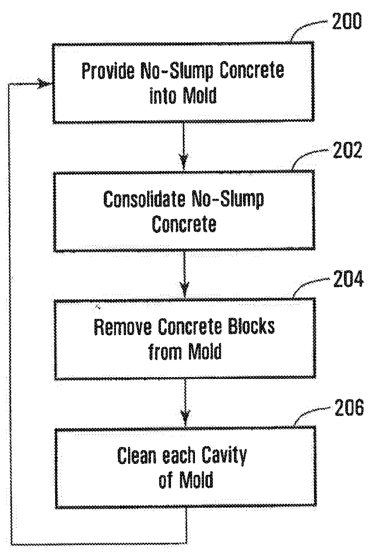

(57) The invention provides a production process of a concrete block by recycling waste, which comprises the following steps of: preparing the concrete block by replacing part of natural fine aggregate with construction waste, and mixing cement, natural coarse aggregate, natural fine aggregate, construction waste particles, coal ash, sand, a water reducing agent, a water repellent, water and reinforced fiber according to a proportion requirement to prepare slurry; manufacturing a single-row-hole concrete block with a scattering cavity; the concrete comprises the following components in percentage by weight: 6.5 to 8.5 percent of water, 13.5 to 16 percent of cement, 17 to 20.5 percent of sand, 3 to 4.5 percent of fly ash, 0.15 to 0.2 percent of water reducing agent, 0.25 to 0.45 percent of water repellent, 0.1 to 0.31 percent of reinforced fiber, 25 to 30 percent of natural coarse aggregate, 15 to 20 percent of natural fine aggregate and 5 to 10 percent of building waste particles. By utilizing the advantages of high static bending intensity, freeze-thaw resistance and higher plane vertical tensile strength of the reinforced fibers, the reinforced fibers are uniformly dispersed in the concrete block to provide fiber cohesiveness, so that the strength of concrete is improved, and the proportion of building waste particles used as aggregate is further improved. The scattering surface composed of the convex hemispherical surface and the concave hemispherical surface is manufactured on the surface of one side wall of the concrete block, most heat is reflected back to a room by the scattering surface, the heat preservation effect of the room is improved, a small part of heat is gathered in the concrete block by the concave part of the concave hemispherical surface, and the problem of temperature difference caused by large environment temperature change of the concrete block is solved.

(71) Chuxiong Henglin Building Materials Co., Ltd., CN