Construction projects with precast elements in Spain 2023: Buildings and infrastructure

ANDECE, the Spanish precast association, regularly reports on new projects of its member companies that were completed using precast elements. This article presents examples from the past few months where structural precast elements were used.

This third and final part concludes the annual review of some of the most important construction projects of ANDECE Members in which precast elements played a vital role. While the first two publications focused on architectural façades [1] and urban spaces [2], this article presents various buildings and civil engineering infrastructure projects where the full potential of precast elements as an industrial solution was demonstrated regarding efficiency, speed of installation, and control at all stages of the process. The ecological aspect also plays an increasingly significant role in the decision-making process, which helps ensure that precast concrete construction systems will become even more popular in the future [3].

1 Hormipresa and Peikko collaborate on the assembly of precast elements for the Hospital del Mar extension in Barcelona

The iconic Hospital del Mar in Barcelona is currently undergoing comprehensive extension and conversion. Its height of more than 40 meters and nine above-ground floors will make the hospital the tallest prefab building on the Iberian Peninsula when completed in 2025.

This project was industrialized using precast concrete elements because this option offers a range of functional benefits while also shortening construction time. In this pioneering project, all columns, slabs, and bracing cores are made of 100% precast elements without welded joints. To speed up the construction process further and meet the extremely demanding deadlines, Hormipresa also sought to identify more “out-of-the-ordinary” solutions, aiming to design the entire project according to circular economy principles, which is why particular attention was paid to using environmentally friendly materials and solutions.

Reorganizing the project in keeping with the original design was not an easy task. Bearing capacities and resistance parameters of all components had to be reverified, which required careful engineering and design work and consideration of all relevant details. The original design contained various elements that were not suitable for industrial production, such as cantilevered parts on all floors, a non-vertical arrangement of columns in the ground plan and elevation, numerous abutted or suspended components, and a façade system to be installed on site.

Due to the central location of the building, the space available on the construction site was extremely limited and there was only one access road. This is why material deliveries had to be carefully planned and coordinated with the additional work to be done to erect the building. Precast elements had to be lifted to a height of 45 meters using cranes and working platforms.

The overall project objectives could only be met thanks to the cooperation with Peikko since the supplier provided a large number of connecting elements such as column shoes, wall shoes, and connectors for the vertical and horizontal connection of rebar to the bracing elements as well as brackets with discontinuous beams and columns.

Switching to precast shortened the construction time for a total area of 28,000 m², including cores and stairwells, to just six months. Since neither temporary supports nor formwork were required, the duration of the work at height could also be reduced. At the same time, Peikko’s rigid connections ensured greater overall safety during assembly. As the building is located directly by the sea, a concrete of compressive strength class C50/60 was used, which impresses with its outstanding quality and durability.

This project is an excellent example of how smooth cooperation can be if all involved parties strive for the same values, priorities, and goals, including safety and cost effectiveness.

Design: Pinearq Arquitectos and Brullet de Luna;

Client: Consorci Mar Parc Salut de Barcelona;

Construction contractor: Acciona.

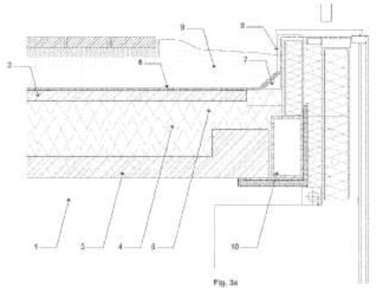

2 Industrialized construction with a prefabricated structural framework and façade system from Precon for student apartments in Salamanca

This project is a residential development for student accommodation in Salamanca with a total built-up area of 26,000 m². It comprises three buildings, each with five above-ground floors, and a parking garage in the basement.

The buildings are aligned in such a way that the communal areas required for the students’ stay are located in the center of the complex.

The concept for the three buildings was based entirely on precast elements, including basement and roof as well as structural framework and façade. Precon was commissioned with designing and constructing the buildings from the foundations to the roof. The company opted for an industrialized construction method in which the load-bearing structure, façade, basement, and connecting shafts were built entirely from precast elements to speed up the process until the building’s inauguration while ensuring the financial viability of the project. This approach ensured maximum efficiency in the construction process – both in terms of architectural functionality and engineering aspects – and in production, as well as quality, cost effectiveness, and short completion times.

The basement design included the following:

Beams and columns;

Single basement walls or double walls;

Precast floor slabs.

This is how the system could be flexibly adapted to the architectural requirements.

The design of the above-ground stories relied on large load-bearing components to ensure the following:

Wide spans and clear views between the panels;

Ceilings without protruding elements;

Load-bearing façade and/or façade with bracing function.

In addition, structural components were fully prefabricated at the factory and finished with different colors and textures as well as thermal insulation to avoid thermal bridging.

The design also included load-bearing, rigid connecting shafts for elevators or stairs that also consist of precast concrete to reinforce the building and secure it against horizontal forces. The complete sanitary installations for the bathrooms were also integrated into the building’s load-bearing partition walls during production to make the best possible use of the space, to increase the usable area, and to shorten installation times.

As a result, total construction time was shortened by 25%, allowing the developer to bring the building into operation several months ahead of schedule. The quality achieved with this construction method was also remarkably high.

Client: Life.be;

Construction contractor: ACR.

3 Precast elements from AG Premoldados for the repair and reconstruction of the bullring grandstand in Lorca (Murcia)

After the city of Lorca was devastated by an earthquake in 2011, the bullring had to close due to the dilapidated condition of the grandstand. The reconstruction project includes the conversion of the arena into a multi-purpose building. In addition to 4,500 seats, the building will include a 1,000 m² commercial area, cultural facilities such as the ambitious bullfighting museum, which tells the multifaceted story of bullfighting in Lorca, and the headquarters of Club Taurino de Lorca, the local bullfighting club. Retaining the exterior façade preserves the original character of the building.

One of the challenges that AG Premoldados faced when designing the precast elements was the precise determination of elevations by carefully surveying the site. Since the radial walls had to be retained, the usual system of prefabricated columns, beams, and stringers could not be used for rebuilding the grandstand. Compensating for the height differences was a huge effort. When building with precast and integrating cutouts, enclosures, or beam shoes directly into the foundation slab, the precast producer must manufacture columns and stringers with pinpoint precision. Deviations must not exceed 5 mm.

Since this project included the restoration of a listed building, the radial walls built more than a hundred years ago had to be adapted. To achieve this, the site had to be surveyed very carefully in advance, which was necessary for the successful execution of the project. The existing radial walls were measured using a 3D scanner. Due to the differences in elevation, a template was created after the survey for each radial wall to determine the exact position of the rows of seats between the upper boxes and the grandstand in the lower area. The differences in height between the existing radial walls were then evened out using a grouting mortar. Once all walls had been leveled, a tachymeter was used to check all wall abutments. Forms were subsequently fabricated based on the survey plan, which corresponded to the actual condition of the structure. The distinctive feature about the reconstruction of the grandstand was that each element was unique: The trapezoidal components had to be installed between the axes of existing radial walls, so no two components were the same. In the last step, the prefabricated elements were assembled.

Client: Lorca City Council;

Construction contractor: Patrimonio Inteligente/Cydemir.

4 Precast elements from Roansa for the visitor and event center of the Circuit de Barcelona-Catalunya racetrack

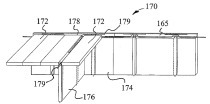

This three-story building accommodates an event space extending over 3,600 m². The publicly accessible roof includes pre-installed anchors for a future canopy. The individual floors are accessed via three 3.60 m wide staircases.

Precast elements were primarily used because of the requirement to shorten construction time as far as reasonably possible. In this project, Roansa was involved in the design, manufacture, and supply of various components:

Columns with unique geometry and brackets on all sides. On one column side, the brackets protrude by 1.90 meters. They also have a variable cross-section so that the floor slab and the grandstand can rest on the overhang. Connections between columns and beams are semi-rigid.

Beams to support the precast floor slabs with a rectangular cross-section; inverted L or T profiles. Beams with a length of 15 m and an overhang of 4 m were installed on the roof.

Civil engineering: Colomer-Rifà SLP;

Client: Circuits de Catalunya, S.L.

5 Involvement of Prefabricados Pujol in the construction of the railway overpass on the C-13 road in Térmens (Lleida)

From now on, more than 6,600 vehicles per day will avoid the level crossing on the C-13 road, which crosses the railway line from La Pobla de Segur to Térmens. Ferrocarrils de la Generalitat (FGC) won the contract for the construction work, which was estimated at 1.6 million euros. The construction phase took a total of 14 months. The removal of the level crossing required the construction of a 25 meter long, 14 meter wide bridge with two 3.5 meter wide lanes, a hard shoulder and a sidewalk in each direction.

Prefabricados Pujol was entrusted with the manufacture and supply of 408 formwork panels and 50 double T-beams (“Zeus” model) almost 26 meters in length, which were placed side by side. Using prestressed precast beams for the bridge deck is one of the best ways to ensure quick and easy execution, simplify quality control, and reduce weight. The contractor also supplied the retaining walls that support the terrain along the rail tracks and retain the soil.

This approach is in line with Ferrocarrils’ ambition to gradually eliminate all level crossings on the railway network.

6 Jacking pipes from Arenzana for an underwater pipeline for the wastewater treatment plant in the Cambérène district of Dakar (Senegal)

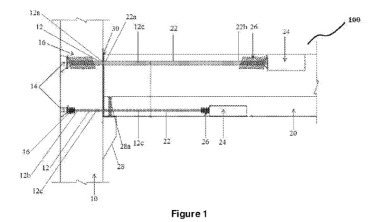

This project aimed to drill and lay a pipeline by means of microtunneling using a closed-shield tunnel boring machine. The wastewater will be purified in the treatment plant located in the city district of Cambérène and then discharged into the sea via this pipeline.

The tunnel bored in a single pass has a length of 1,200 m, an outer diameter of 2.50 m, and a subsea outlet at a depth of 30 m. Tunnel boring included laying of 500 jacking pipes and 13 custom pipe systems for the installation of intermediate compressor stations.

Top-quality Arenzana reinforced concrete jacking pipes with an internal diameter of 2,000 mm, an external diameter of 2,500 mm, a wall thickness of 250 mm and an effective length of 2,400 mm were used for tunneling. The pipes were manufactured using radial grouting to obtain a fully compacted, non-porous concrete that can withstand a pressure of more than 50 MPa. After concrete pouring and hardening, pipes were ground completely smooth so that their surfaces match perfectly and a uniform jacking force is applied during the laying process.

To ensure that pipes are completely sealed, their spigot ends were mechanically machined using digital control and two grooves were milled to accommodate two Arpon rubber seals. Tightness of the system was checked in ten leak tests on the assembled pipes applying a water pressure of 3.0 bar acting on the pipes from the outside.

To transfer shear forces between the pipes, a pressure transfer ring made of knot-free pine wood was attached to the rear pipe end. For the sake of safety and tightness, two additional seals were installed that are pressed against each other to apply pressure to the pine wood.

Anchor bolts are attached to the top side for lowering and handling the pipes. These bolts were sealed before the pipes were pushed into the tunnel.

To inject bentonite and lubricate the tunnel during boring, metal injection nozzles with a 1” thread, non-return valves and valve caps were fitted in the middle of every third pipe at a 120° angle.

Custom pipes for the intermediate compressor stations consist of two specially designed pipe sections, the so-called “flow” and “return” pipes, fitted with a press collar and “D” type seals with thrust ring.

Client: Office National de l’Assainissement du Senegal (ONAS);

Construction contractor: Incatema Consulting & Engineering;

Tunneling contractor: Eurohinca.

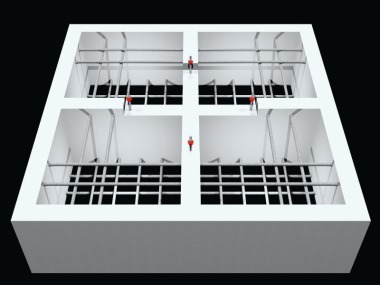

7 Precast roof elements from Suberolita for a water reservoir

The roof consists of precast elements suitable for an aggressive environment. Both the rectangular beams with a bearing surface of 40 cm and the precast floor with a height of 15 cm were designed such that a special coating could be applied, and that the reinforcement is protected by the concrete. The columns are arranged so that they form a grid and create optimum edges for bearing the loads of the structure. This is why the accurate arrangement of the columns is crucial.

In addition, heavy-duty 5 m long slabs and 6 m long beams had to be used owing to the special features of the project in terms of access, assembly, etc.

Floor slabs were prefabricated so that they reduce the number of roof edges and allow the reinforcement to be enclosed more effectively compared to other prefabricated elements.

Project: Construction of a new water reservoir in Berga (Barcelona);

Client: Aguas de Osona.

8 Installation of a stormwater drainage channel using reinforced concrete box culverts supplied by TPPalau

This project involved the construction of a new channel to drain stormwater away from Vila-Seca (Tarragona) and from the A-7, C-31B and TV-3146 rural roads to ensure stormwater drainage outside the town.

The project was completed using precast reinforced concrete box culverts from TPPalau measuring 3,000 × 2,000 mm that were designed to resist the loads of rural roads according to the Spanish IAP-11 code.

Conclusion

Each of the eight projects discussed above – four buildings with specific structural requirements and four different civil engineering projects – posed its own challenges. They once again demonstrated the outstanding adaptability and technological progress made by Spanish precast concrete manufacturers [4].

CONTACT

ANDECE

Spanischer Verband der Betonfertigteilindustrie/Spanish Precast Concrete Industry Association

C/Diego de León 47

Edificio Melior

28006 Madrid/Spain

+34 913 238 275