Construction with a future: Max Bögl Group relies on automated reinforcement production by Progress Group

The construction industry is undergoing a period of transition. Companies like Max Bögl are faced with new challenges owing to the shortage of skilled labor and the demand for sustainable construction methods. With the Progress Group as partner by their side, Max Bögl opts for innovative solutions for the automated reinforcement production, thus equipping for the future.

Automation increases efficiency and quality

Progress Group offers ground-breaking technologies, supporting building contractors like Max Bögl to increase their efficiency and to meet the high quality standards simultaneously. Highly automated machines are the key to success in a modern construction sector.

Innovative solutions for the production of reinforcement

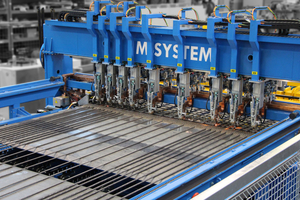

Manuel processing of reinforcement is time consuming and labor intensive. The M-System mesh welding line of the Progress Group provided with beam bending system and individual bending heads as integrated mesh welding system is revolutionizing the production of reinforcement. The system allows for substantial time and staff savings and ensures an efficient manufacturing process of bent reinforcement elements. The Max Bögl group of companies has already five of these systems at various locations in operation.

Modernization as driving force of the future

Max Bögl is continuously investing in the modernization of their reinforcement production. The Wire Center, automatically straightening, cutting and laying of reinforcement steel from the coil, was installed in a large precast concrete plant of the group. The Versa lattice girder welding machine is increasing the efficiency in manufacturing of lattice girders due to the automated height adjustment during production. The Form Master shuttering and deshuttering robot provides for a fully automated shuttering process in the factory.

Special machines for major projects

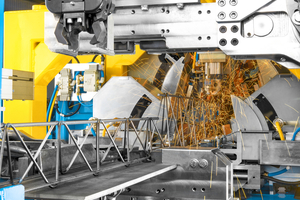

When it comes to the major European tunnel projects, Max Bögl also benefits from the expertise of the Progress Group. Innovative equipment and manufacturing processes enable automated production of reinforcement wire mesh, ladders and complete reinforcement cages, being exactly tailored to the requirements of the respective projects.

The cooperation between Max Bögl and Progress Group is an example par excellence for successful team work and future-orientated thinking. Using state-of-the-art reinforcement technology and a high degree of automation, Max Bögl is equipped at best in order to master the challenges of the future.

CONTACT

Max Bögl Fertigteilwerke GmbH & Co. KG

Max-Bögl-Straße 1

92369 Sengenthal /Germany

+49 9181 909-0

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159

optimized material utilization