Controlled fiber orientation in steel-fiber-reinforced precast elements

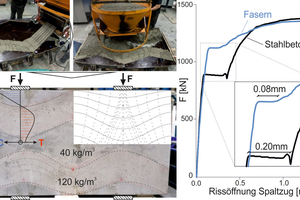

Fiber orientation has a significant effect on the load-bearing capacity of steel-fiber-reinforced concrete (SFRC) components. To optimize this orientation, an extrusion-based concreting method including narrow parallel channels was developed, which allows for an almost unidimensional control of fiber orientation. This method is particularly suitable for local strengthening of highly loaded precast element sections to make them resistant to stress peaks. This is the case, for example, for sections of tunnel segments to which pressing forces are applied. In the area of the dominant tensile stress resulting from the load application, an SFRC with a high fiber content of 120 kg/m³ (60 + 60 kg/m³ of micro and macro fibers, respectively) is extruded in the direction of the principal normal stresses to achieve the most effective fiber orientation. In all other areas, a conventional steel-fiber-reinforced concrete containing 40 kg/m3 of steel fibers is placed (hybrid material use). Feasibility of this process was demonstrated on a segment with such hybrid reinforcement and concentrated, doubly symmetrical loading (Fig. 1 left). This element thus possesses a 50 % higher bearing capacity compared to the design without controlled fiber orientation.

In the experiment, local strut failure occurs in the load application

area, while the fiber-reinforced concrete can absorb tensile splitting forces. This is also shown by a comparative test of a conventional, highly reinforced tunnel segment with the same ultimate load in which tensile forces are transferred through steel rebar. However, the optimized segment with hybrid reinforcement exhibits a much better cracking pattern. The dominant splitting tensile crack has a 40 % narrower opening width prior to activ-ating additional load reserves (Fig. 1 right). Optimized fiber orientation can thus improve both load-bearing capacity and serviceability, for instance in respect of impermeability requirements.