Drawn-arc stud welding (783): process sequence, welding defects and blowing-arc-effect

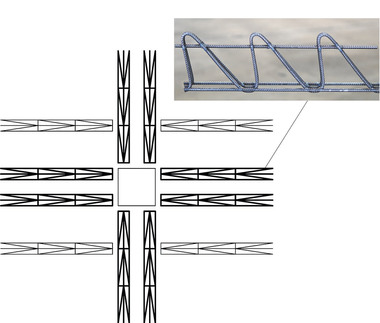

Drawn arc stud welding (ISO 4063-783) describes a fully mechanized pressure welding process for joining primarily pin-shaped fastening or functional elements (such as a shear connector) to a mainly flat workpiece surface. The thermal energy of an electric arc and the force of the stud kinematics are used to create a material bond. This stud welding process is relevant for joining large-dimensioned studs with a diameter of up to 25 mm to be welded with the support of a ceramic ferrule or shielding gas. The process has the great advantage of a short process time of 100 ms to a maximum of 2000 ms.

The main standard for arc stud welding is ISO 14555, while standardized welding studs such as the shear connectors are described in ISO 13918.

Any welding defects that occur must be detected and eliminated. Visual inspection serves as a non-destructive test during production. The weld bead shape, surface and the stud length after welding are examined. Different characteristics can indicate different causes. The operating personnel and the welding supervisor must be able to recognize these faults.

The blowing-arc-effect is a phenomenon that can only occur when welding with an arc. For drawn arc stud welding, the blowing-arc-effect is a challenge, especially for studs with larger diameters, as longer welding times favor the blowing effect. Electromagnetic fields, which unavoidably form around current-carrying conductors, can cause welding irregularities or, in rare cases, even improve the welding quality.