Dutch limestone producer Calduran invests to stay ahead

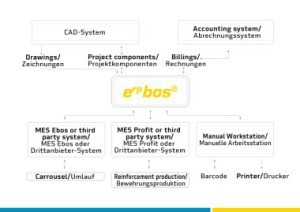

Away from planning and managing via individual systems and interfaces, towards one system for all business and production processes specific to the precast industry. The limestone producer Calduran, based in the Netherlands and part of the CRH Group, has found the ideal solution with Progress Software Development and their Erpbos software.

Away from planning and managing via individual systems and interfaces, towards one system for all business and production processes specific to the precast industry. Calduran, the specialist for limestone applications based in the Netherlands and part of the CRH Group, has found the ideal solution with Progress Software Development and their Erpbos software. For both plants in Harderwijk and Hoogersmilde, Calduran worked closely with Progress to implement the system for 120 employees. The choice for Progress Software Development, a company of Progress Group, was made not only because of the specific ERP solution, but also because of their expertise in the entire business process of the precast industry.

Time for a new system

Before implementing Erpbos, Calduran worked with separate systems and interfaces that often had to be adapted to meet the specific needs of their work processes. Therefore, the decision for Erpbos in 2021 was made very consciously in order to be able to cover all processes in a uniform system and to integrate a system that is specifically designed for the precast industry. “A generic ERP system would have taken way more time and effort”, states Peter de Leeuw, Caldurans Group Service Director.

Calduran – over a hundred years of experience

In 1900 Rudolf Roelfsema discovered calcium-silicate blocks at a trade show in Berlin. Five years later he started his industrial production plant in Hoogersmilde. He chose this location because this area of the Netherlands provides the most important basic raw material: sand. Over time, the production evolved and led to a merger with their other production site in Harderwijk in 2004 to form Calduran Kalkzandsteen. Calduran is an important player on the Dutch market for building materials for industrial and residential buildings and a market leader for calcium-silicate blocks and elements. Key factors of their business are innovation, sustainability, and growth, which are also core elements of the Progress Group philosophy. From their two plants with a total of 250 employees, they supply not only their main market, the Netherlands, but also Belgium and Germany.

How did the implementation of Erpbos work?

Erpbos, specifically developed for the precast industry, could be easily adapted to the standard processes of calcium silicate production and supply. The project was started with a detailed design phase that included all workflows. Calduran’s team consisted of Business Process Owners, covering all workstreams, supported by key-users and the local IT-team, all working with the Erpbos-team of Progress Software Development. In total, the core team consisted of 8 people and the whole team of up to 25 people. Throughout the implementation, both teams worked closely together, jointly analyzing the requirements of the processes and adapting the Erpbos system accordingly, resulting in very good and effective cooperation.

What exactly is Erpbos used for now?

Erpbos is used to manage all products and services within Calduran. Before, for example, the wall solution with limestones instead of elements could not be mapped at all in the previous ERP system, which meant that a lot had to be done manually.

Erpbos is also connected to the production systems to manage the sawing robot and to the engineering system, which provides the technical details for the bill of resources and the geometry of the product.

With Erpbos a platform has been created for future developments, support, and optimization of the company. Peter de Leeuw states: „In the beginning, users were concerned that the functionality and speed of processing data in the system would be lost. But after only a few weeks, there was a clear improvement in the processing speed in the Erpbos system. After a few months, all employees agreed, that Erpbos was a significant improvement compared to the previous system.“

Smooth projects and satisfied customers

Peter de Leeuw explains: „In our old system we had many problems with printing loading and delivery notes: it sometimes took minutes, or they were not printed at all. This often led to long queues of trucks at the production sites, which resulted in significant costs due to complaints from customers and transport companies. Since the introduction of Erpbos no more malfunctions have occurred.“ Now, in addition, transport costs can be calculated correctly and accurately at freight level per site, ensuring cost certainty and budget adherence. Therefore, unforeseeable extra costs and customer complaints are no longer an issue.

Digitalization increases competitiveness

The digital mapping of the entire process, from the first customer contact to the final delivery, has significantly minimized effort and prevented errors that would otherwise only have become apparent later on in the process. Focusing on the various process steps, a model-based approach enables optimal use and planning of resources and capacities, for example in the engineering process. This has a particularly positive influence on the cost factor. The system provides a better insight into the cost development and turnover improvement per customer and project, which leads to a clear review of the profit margin. This is a great advantage for the business analysis.

Ready for the future

Both Calduran and Progress Software Development look back on a successful project and count on a long-term, trusting cooperation. “It is important for our company to have a reliable and trustworthy partner for the future, sized in such a way that we do not have to rely on just one person. With Progress Software Development we have found the balance between long-term reliablity, many years of expertise and flexibility in the way of working”, resumes Peter de Leeuw, Caldurans Group Service Director.

CONTACT

Calduran Kalkzandsteen

Einsteinstraat 5

3846 BH Harderwijk/Netherlands

+31 (0)341 464 000

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+ 39 0472 979159