Efficiency and quality enhancement with integrated software solutions

Advanced ERP systems are able to plan and control all business and production proc-esses – also in the precast concrete industry. They therefore make a significant contribution to optimal coordination of all processes – including the whole range of activities in sales, calculation, project management, production and erection planning, logistics, materials management, controlling, and human resources. Together with modern plants and machines, it is thus possible to put the concept of “Industry 4.0” into practice, at whose heart lie intelligent production, networking and transparency at its core.

Progress Group: strong focus on software development

The Progress Group, whose subsidiaries have been successfully active in the industry for decades, recognized early on the significance of automation and industry-specific software solutions. The development of software for individual machines and systems has been in the focus of Group efforts for decades. ebos, a package solution for all production processes in precast plants, was developed some years ago: an MES system (Manufacturing Execution System) that has already been implemented in dozens of plants worldwide. In addition, ProFit, an MES system specifically for manufacturers of reinforcement, has become well established. The launch of the sector-specific erpbos ERP system rounded out the portfolio of the Progress Group on the software sector.

Strengthening the software sector

To advance this sector still more forcefully, Progress founded its own software company within its Group. The company, Progress Software Development (PSD), is the seventh Group subsidiary active in the precast concrete industry. In addition to machinery and plant engineering as the first Group pillar and its own precast production as the second, Progress is now further strengthened by its own software development. With its founding, the Progress Group, moreover, emphasizes its claim on being a one-stop supplier for the industry: with a product range that covers everything from carrousel plants and machinery for reinforcement production, to special moulds and production systems for prestressed elements, and including its own MES and ERP systems.

Knowhow “from the

industry – for the industry”

Knowledge gained in the course of many years is an important cornerstone of software development at PSD. Drawing on the experience of sister companies from engineering – Ebawe Anlagentechnik, Progress Maschinen & Automation, Echo Precast Engineering, Tecnocom and Ultra-Span – the development teams at Brixen in Italy and Frankfurt in Germany succeed in creating solutions tailored to the industry’s many and various specific needs and requirements. “We profit greatly from the knowledge of the entire Group,” explains Messner, MES Senior Developer at PSD.

Cutting-edge ERP system

for the precast industry

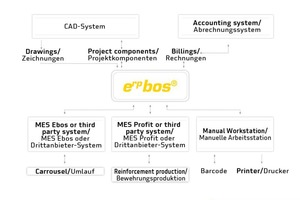

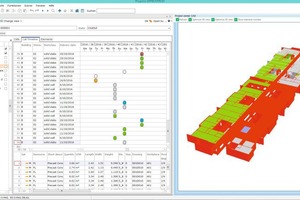

The erpbos ERP system is based on practical knowledge gained by all companies of the Progress Group in cooperation with the ERP specialists at Softbauware and supports planning and control of all business and production processes in its precast companies. The ERP system ensures that the entire process chain is perfectly integrated: from sales to planning and production, and all the way to accounting.

The many modules from erpbos support the smooth flow of these processes. In addition to the typical ERP functions, DMS, CRM and BI were combined into one system. DMS ensures uniform filing of documents, CRM consists of a central customer file with the respective app, and BI as analysis platform generates condensed trans-sectoral information. “Erpbos, with all its functions and interfaces, has the best prerequisites for really bringing the Industrie 4.0 concept to the precast industry,” emphasizes Sirio Sperandio, ERP Software Developer at PSD.

Integration of BIM systems

Open interfaces prevent isolated applications and facilitate integration into an existing structure. “This eliminates the interface problems with which many companies are confronted,” explains Messner. Through integration of BIM systems, for example, production and delivery schedules or project and materials costs can be directly brought into context with BIM. “That is requisite to a transparent overview,” adds Sperandio. Time and cost factors can in this way be brought under permanent control, and deviations can be instantly recognized. An intuitive user interface contributes to facilitating convenient, uncomplicated, and rapid work.

Successful

implementation worldwide

Successful worldwide acceptance by precasters of ProFit, ebos, and erpbos confirms the great demand existing for sector-specific software solutions. Growing competition in the precast industry and demanding customers’ expectations call for the shortest possible delivery times, competitive prices for high-quality products, as well as effective customer management.

At the same time, standard software solutions are hardly suitable for the industry: “The precast industry is very specific and does not pose the same requirements as other industries,” says Messner. Sperandio adds: “The difference between epos and other ERP systems is that our collective knowhow – including engineering, production of precast products, and software development itself – has been combined in one solution.” As a company deeply rooted in the precast industry, PSD with its software products supports smooth process flows, continuity, monitoring, and tracking – all of which are factors that influence success on the precast market.