Effective steel cutters for Betonsteinwerk Müller

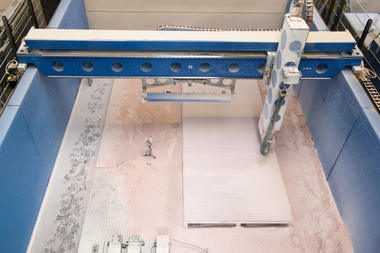

The terms craftsmanship and one-offs are usually not associated with large concrete elements. But what appears to be heavy industrial production is often an individually manufactured piece of craftsmanship. This becomes readily clear when visiting the Bernhard Müller precast plant located in Achern, in southern Germany. It also becomes quite evident that − although only a few – but some very special tools come in quite useful in this plant.

Manufacture of concrete elements directly at the construction site is often complex and expensive. The use of precast elements is therefore lived practice. Precast plants effectively produce both standardized concrete elements and individually manufactured products. The quality of the elements, moreover – for example, a more uniform concrete density and upside-down casting – is consistently higher compared to elements manufactured at the construction site.

“We manufacture both standard precast elements and series made to the specifications of customers, as well as small runs,” reports Dominic Decker. He is production manager at Bernhard Müller Betonsteinwerk GmbH in Achern and is more than familiar with the materials used and their properties. One of the specialties of the Achern precaster are pipe sections with V and egg profiles and interior plastics coating for water conduits and sewers. While the standard products are mostly used in the home region, customized elements are also transported over long distances and across borders.

All elements are one-offs

The small series of various sizes and the individual concrete elements made in Achern are especially produced to the specifications of customers’ requirements and are all individually manufactured: such as basic elements for masts or small bridges. Not only the formwork, but the reinforcement as well must of course be individually manufactured. For this purpose, all the welded fabric is individually cut to size and provided with the necessary recesses to fit the respective openings as planned in the elements. Part of the construction looks like an over-dimensioned assembly set that still needs to be bent and cut out in some places.

For cutting the welded fabric, the precaster Bernhard Müller Betonsteinwerk in Achern uses five cutting tools made by the German manufacturer Krenn, which specializes in developing cutting tools, especially for the construction industry and the building trade. Among the five tools that are in constant use in Achern are pneumatic tools from the Krenn product line. For precast production, compressed-air hoses are placed at central points, from which the tools can be quickly coupled and uncoupled, depending on where they are needed.

For Dominic Decker, an important aspect in using the tools is prevention of flying sparks. The pneumatic steel cutters separate even thick reinforcement bars cleanly, rapidly and without the need for additional precautionary measures at the workplace. The tools can, moreover, be used at any place in the production hall as well as outdoors.

For Decker, in addition to performance, the durability of the Krenn tools is a significant point that speaks in favor of the machines. When he joined the company four years ago, the pneumatic steel cutters were already in use. The exchangeable blades in the cutting head are swapped at Bernhard Müller Betonsteinwerk by its own workers. Apart from these, there are virtually no wear parts that need to be replaced. For periodically scheduled maintenance, the tools are, of course, sent to Krenn’s head office in Neusäss, near Augsburg in Germany. “If a repair does become necessary, we handle that together with the regular maintenance, saving ourselves an additional cycle,” reports Decker. He is very satisfied with the procedure: “Logistics, preparation of bids and contract execution take place very fast, which means that downtime of the tools is minimal.” In Deckers view, communications with the tool maker functions perfectly, and inquiries are answered quickly and competently – “absolutely reliably,” says Decker.

Cutting right to the corner

The high quality of the cutting heads is an additional special feature of the Krenn tools. The pneumatic cutting tools are designed to be especially slender so as to securely enable close cutting to the material junctions of the welded fabric, as well as in confined spaces. In addition, the machines can also be fitted with special heads for flush cutting and for separating high-strength prestressing steel and prestressing steel strands. In the course of the company’s 75 years of existence, the product range has continuously been further developed, with the focus always on ergonomically and safely cutting and separating steel and other metals.

Likewise, it is accordingly not surprising that Krenn was the first supplier in Europe to present, already in 1992, the first battery-powered hydraulic steel cutter, according to the supplier – at that time still with the battery technology of the first generation. Today, cutting-edge and high-performance lithium-ion batteries power the current battery-powered tools from Krenn. Now as before, final assembly of Krenn tools takes place at the company’s head office in Neusäss, near Augsburg. This is also where product development takes place in close collaboration with clients: which includes design of special cutting tools, often to series maturity.

Battery power as alternative

The battery-powered hydraulic steel cutters in the Krenn product line are for Dominic Decker a good alternative to the currently used pneumatic tools, since they offer still higher degrees of freedom. But new acquisition of battery-powered cutters is currently not under consideration, since their robustness and performance do not match that of the pneumatic tools from Krenn. They also require especially little maintenance and can sustain high cutting frequencies in continuous operation.” There is simply no need to exchange tools here, which would be difficult when engaged in budget talks,” explains Decker with a twinkle in his eyes.

As regards the continued use of the tools and capacity utilization of the workforce of around 35 in precast production in Achern, Dominic Decker is not worried : “Concrete elements will continue to be used in the future, especially where communal areas of use and projects of water management are concerned. The respective requirements placed on the construction elements used, in relation to costs, now as before speak for our material.” Cutting welded fabric to exact sizes will continue to be among the company’s main functions.