Flexible polyurethane formliners for the

design of textured precast concrete elements and façade elements

The expectations on the concrete manufacturer are already growing at the beginning of a project when it comes to the conception of a suitable formwork or textured formliner. In order to meet these requirements, Wasa provides comprehensive services ranging from virtual 3D models through to individually manufactured casting molds and formliners.

Ambitious construction projects are evolving from the classical in-situ concrete formwork towards prefabricated and customized precast concrete elements. To realize the visions of architects and planners, the demand on the concrete manufacturer is already growing at the beginning of a project when it comes to the conception of a suitable formwork or textured formliner. For meeting these requirements, Wasa provides comprehensive services ranging from virtual 3D models through to individually manufactured casting molds and formliners.

Standardized / uniform data and commonly shared knowledge

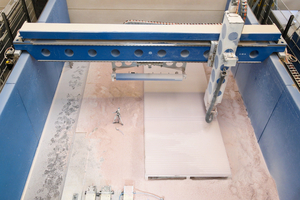

For this purpose, Wasa creates a virtual, scale 3D model. The CAD data of the model can be provided by the customer as well, being integrated seamlessly into the CAD planning tool of Wasa. In particular, owing to the interconnection of standardized data, correlations are displayed on the screen within a short time and are tested in virtual environments. Many questions are clarified directly at the 3D model on the tablet or on the monitor.

All data required are linked up with an assembly unit. Shop drawings, item lists for procurement as well as other interfaces, such as CAM programming of the CNC milling machines for the production of models and tools, are controlled by means of the assembly unit. The digital workflow leads to a new quality of communication, and language barriers can be reduced as well as broken.

The surfaces of the models are smoothed following the CNC machining. For a smooth and closed surface, the models get a micro-fine coating. Because of the mat surface, the release agent adheres to the textured formliner evenly and homogeneously later.

The different surface structures of Wasa are organized in three categories

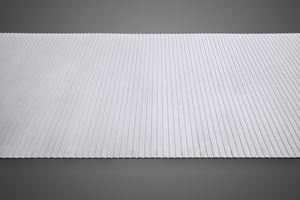

Standard textured formliners with various characteristics can be selected from the patterns of the Artcast, Stonecast or Woodcast series for the designing of concrete. Starting with sand-like surfaces through to coarse quarry stone, an infinite variety of possible structures is available to the concrete manufacturer. Moreover, Wasa does not limit itself to a two-dimensional surface exclusively when it comes to designing. Depending on the requirements, for example, lateral structures of natural stone are modeled in the in-house model making department according to the design specifications. The combination of traditional craftsman’s techniques and modern manufacturing methods allows to realize complex and filigree three-dimensional models which were unthinkable previously. As far as the implementation is concerned, Wasa can draw on comprehensive experience gained over many years in the field of wet-cast.

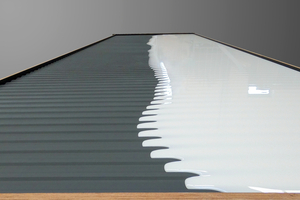

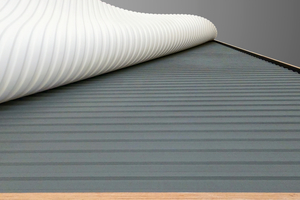

The often tried and tested Wasa Pur is used for the manufacture of the flexible polyurethane formliners in Shore A65 standard hardness. The two-component polyurethane especially developed for the large-sized formliners and molds is convincing because of its very good flow properties, long open pot life and the corresponding ease of processing.

For increasing the reproducibility of the polyurethane formliners and molds sustainably, Wasa does not use any mineral fillers such as calcium carbonate or plasticizers in the polyurethane system. Due to the resulting low system density of 1.12 kg/l, the user gets up to 30 % more mold volume in comparison to common competitive products. Wasa chooses a layer thickness of at least 15 mm for a formliner, which is very generous, but with the same input of material in relation to the weight of the formliner. The increased layer thickness has a direct and positive influence on the tensile strength, dimensional stability and reusability of the concrete formliner.

Wasa Pur is a low-viscosity two-component casting resin and is suited very well for large-sized molds and formliners. There are container sizes from 7.5 to 1,000 kg available for concrete manufacturers with their own formwork construction and using own molds. In this way, they can order the quantity required according to their needs.

New Wasa Release agent

For the simplest possible application, Wasa offers a water-based release agent. The new Wasa Release agent is a further development from the field of wet-cast. The ready-to-use emulsion is solvent-free and thus, can be applied as a micro-fine layer – using a portable airless system, for example. Wetting the entire surface of the textured formliner is of importance in this regard. Before using the textured formliner for the first time, the application of the release agent should be repeated two to three times in order to saturate the absorbent and vacuum-forming PU layer.

The fine dosage of Wasa Concrete Release keeps overspray as low as possible. The consumption of the required quantity of release agent is reduced, resulting in a better working environment for the user. Moreover, the release agent has a maintaining property on the textured formliner and increases the alkali resistance to the concrete.

Textured formliners without limits on the reusability

With the products and services coordinated with each other for the precast concrete industry, Wasa offers textured formliners without limits on the reusability. In combination with the Wasa Shuttering system that can be used universally, the concrete manufacturer is also provided with an additional solution for a modular formwork system for two-dimensional precast concrete elements.

The particular advantages of the system are the freely selectable dimensions and thus the possible implementation of most diverse applications, from palisades, to patio slabs, through to precast concrete floor slabs, with a single system and the related enormous potential for savings in individual mold making.