Efficiency in harmony with nature

The implications of the climate change on the environment have an increasing effect on the future. In this regard, industry plays an important role because it is significantly contributing to the emission of greenhouse gases. Therefore, efficiency and sustainability must go hand in hand to allow an economy that is fit for the future, but is also in accordance with legal requirements on climate protection. To reach this goal, industrial processes need to be continuously optimized and made more efficient. Wasa has adopted this aim as well and strives for the reduction of its CO2 emissions.

Thus, the company based in Darmstadt and Neubrunn (Thuringia) has already implemented an Energy Management System according to DIN EN ISO 50001 in 2016 and is continuously working on improvements. It was possible to reduce the energy demand at the production site in Neubrunn by 13 % within five years (reference period 2016 to 2021). At an annual power consumption of 3.6 million kWh and a gas consumption of nearly 5 million kWh, this is a considerable value, in particular, in today‘s world and has major economic importance given the continuously increasing energy prices.

One of the biggest energy savings was achieved by centralizing the compressed air and implementing a system for detecting and fixing of leakages. The current compressor as well as the dryer for the plastic granulates are to be modernized in additional steps. Furthermore, the existing system is to be supplemented by a heat exchanger. These investments allow saving additional 11 tons of CO2 per year.

The large floor space of the production hall of more than 2.5 ha provides Wasa with an exceptional opportunity to generate electricity through photovoltaic systems. A 350 kWp system was installed at the end of the year 2023 and two further systems will be added after a roof refurbishment required on static reasons in 2025 and 2026. „With the start-up of all three systems, we will be able to save additional 520 tons of CO2 annually,“ states Jannik Webel, responsible member of the board at the Thuringia site.

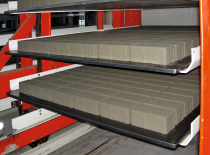

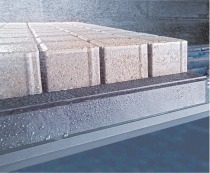

Sustainability is written large for the Wasa Uniplast Ultra too. Here Wasa opts for a 100% recycled plastic exclusively, the most part of which is purchased in Germany so as to enhance the green footprint by short transport routes. This effect is furthermore strengthened by the long service life of the all-plastic board and the possibility of re-grinding.

„As a result, the Wasa Uniplast Ultra is the only board made of all-plastic material on the market that really deserves the term sustainable: because not only the re-grinding is a very CO2-low way of extending the service life of the all-plastic board. The boards can also be recycled completely after the definite end of their operating time and can then be returned to the material cycle,“ explains Matthias Bechthold, chairman of the management board of Wasa AG.

180 tons of CO2 emissions saved by new cooling system

Some of the customers of Wasa‘s all-plastic boards have thus been working for more than 25 years with these production boards before they are recycled.

Also the raw materials used for the Wasa Uniplast Ultra make a huge contribution to environmental and climate protection: Wasa processes around fifteen million kilograms – namely 15.000 tons – of recycled plastic material in its all-plastic boards every year. „These are all together plastic materials which otherwise would have to be supplied to thermal utilization or stored in landfills – with the well-known consequences for humans and the environment, such as microplastics, for example,“ explains Matthias Bechtold.

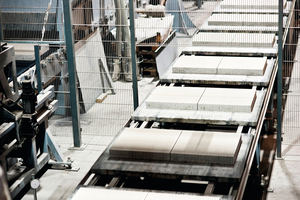

The topic of energy and the associated savings of carbon dioxide is also taken seriously when it comes to the implementation of the latest plant equipment for the production of the all-plastic boards. Hence, a 1.2km-long water supply line was installed to a nearby water well, which Wasa acquired for own purposes, especially for the new and meanwhile fourth plastic processing plant. This new type of climate-neutral cooling is saving a total of 180 tons of CO2 emissions annually, since thermal oil was used for cooling the molds previously.

In addition to the installation of three electric charging stations by 2025, Wasa also supports nature conservation. Wasa, for example, has a meadow orchard, which is strictly protected under nature conservation law due to the rare occurrence of the Dactylorhiza incarnata – a species of marsh orchids belonging to the genus Dactylorhiza – especially since Wasa‘s meadow orchard is the only known natural location in the entire district where the orchid flowers.

Thus, Wasa attaches great importance to the topic of sustainability, which extends not only to the company‘s products, but also to their production processes.

climate protection: