Employee garage reinforced with glass fiber and carbon

J. Lehde GmbH is testing the combination of glass fiber and concrete for the first time. For the construction of an employee garage, precast reinforced concrete components were manufactured that contain reinforcement elements made of glass fiber or carbon instead of conventional steel reinforcement.

Martin Risse, head of the Research & Development team at Lehde: “This topic is being discussed controversially in the industry. We wanted to gain first-hand experience. Our colleague Christian Trost now has a new garage. And as an expert, he can monitor the critical points on a daily basis and continuously update the test documentation.”

50% less weight – improved carbon footprint

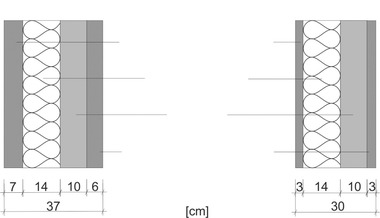

The use of glass fiber elements can save around 50% of concrete. This results in lighter components while maintaining the same degree of stability, reduces transportation cost, permits the use of smaller construction cranes and improves the carbon footprint.

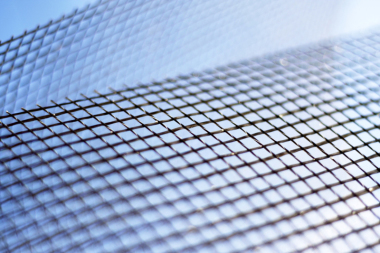

Precast reinforced concrete components are always reinforced in order to enable the concrete to absorb not only compressive loading but also tensile stress. This requires mats or even cages made of steel wire mesh. These are then cast in concrete during production. In principle, the same can be done with glass fiber elements. They cannot be bent, however, as bending would result in breaking. Glass-fiber reinforcement must therefore be either purchased ready-made, or the required mesh structures must be put together using plastic clips.

Martin Risse: “We will take our time to look at it and gain first-hand experience. Glass fiber reinforced components are still comparatively expensive. But we want to have done our homework when the products are competitive in terms of technology and pricing.” Lehde’s chief architect Christian Trost will keep a close eye on his private glass fiber reinforced garage over the next three years and report any changes, cracking or settling back to the R&D team at Lehde.