Empowering Progress: Byggelement’s turnkey sustainable production solution

Automated machinery and integrated software are the key for a sustainable production of sustainable products. Byggelement expanded its production with two fully automated and digitalized factories from one turnkey provider, Progress Group, to become the leading company in regards of sustainable building with precast concrete in Sweden. Operating a total of four plants, this innovative company is paving the path to a more environmentally friendly yet cost-effective and long-lasting way of building in the Nordics.

Innovative goals in a conservative industry

In 2020, the group of companies had set two goals for itself: To be the number one with regard to environmental performance in terms of the lowest carbon emissions in the Swedish market, and to lead the race of automation in the industry.

This endeavor started from the search for an alternative binder, which is essential for a more sustainable concrete since cement is the largest contributor of carbon in precast. Having started with 10 percent, the company has reached more than 60 percent of alternative binders in their concrete mix in the meantime. In addition, sourcing of the reinforcement changed as Byggelement switched to suppliers that have the lowest carbon footprint in Europe. The company only uses green electricity generated from wind and hydro power, resulting in zero emissions from the power used. Byggelement takes the lead in transporting precast on railroads over long distances. Testing new binders, finding different ways of production – given the fact that the curing time increases with alternative binders – as well as identifying the right automation, software, and steel supplier: All these activities required major investment. Based on these efforts, the company specified a product referred to as ECO-Precast since the Swedish market has changed significantly. Even though customers are not ready to pay more for the sustainable solution, investors are willing to choose this option provided its pricing is on par with other solutions. This is why having the lowest carbon emissions is currently turning into a competitive advantage.

“Compared to the ordinary way of producing where you use 100 percent cement as binder and buy just the cheapest reinforcement, where you do not care about emissions and use whatever electricity is the cheapest, we have reduced our carbon footprint by approximately 50 percent,” explain Carl Rülcker, Chairman and CEO of Peab Byggsystem AB, and Tobias Rönje, CEO of Byggelement.

Automation and digitalization: Crucial for sustainable production

Byggelement concluded that such precast products can only be manufactured in a fully automated process using a software solution that optimizes the process as productivity goes down due to the longer curing time of the new binders. According to Carl Rülcker and Tobias Rönje, they were discussing possible solutions with a number of suppliers, with the aim of implementing a high degree of automation and using higher alternative binder ratios. According to them, Progress came up with the best answers to these questions, as well as with the closest personal relationship: “We found a partner that offered both: the ‘hardware’ – machinery – and the software from a single source, combined with hands-on consultancy and support. We wanted to have a turnkey solution, and this is the reason why we chose Progress Group. When it comes to such a big investment, you want to lower the risk and you want to know that it will work right from the day you push the button, so we signed a turnkey solution contract with Progress for both factories. The one in Hallstahammar produces mainly solid walls, half sandwich walls and sandwich walls, and the one in Ucklum produces concrete slabs.“

The iPhone of the precast industry

This decision was influenced by the fact that Progress Group is one of the most experienced players on the market, especially when it comes to machinery fabricating reinforcement from the coil. The M-System BlueMesh mesh welding plant with integrated bending system can produce complex cages in wire diameters from 6 to 16 mm while bringing a huge advantage for Byggelement by effectively saving time and reducing labor costs. The carousel plant in Hallstahammar ensures an output of three pallets per hour and can produce up to 2.9 m high slabs. More specifically, it is equipped with machinery primarily designed for solid and sandwich walls such as a leveling beam and power trowel. The fully automated Form Master shuttering and deshuttering robot, the eCon Drive concrete spreader, a pallet stacker, a compacting system, tilting equipment, and a run-off carriage are just some of the machines installed at the plant to make the work environment safer and more efficient at the same time.

On the other hand, the plant in Ucklum produces up to 3 m wide half slabs on 70 pallets and features a very high degree of automation. Finished elements are lifted by a crane using a demolding crossbeam.

However, the key to the successful cooperation of the two groups of companies was that Progress Group could combine automation and digitalization, which are interlinked and communicate with each other. “It is like with the iPhone: Maybe you can find a better processor or a better camera in another phone individually, but Progress Group managed to put it all together under one roof and made it easy to use,” says Carl Rülcker, adding: “When visiting the headquarters of Progress Group, which is a big show room for innovative precast elements, as well as their own plant nearby where the machinery and software are tested in-service for their own precast production, we saw how aligned they are with our own quality requirements. Progress Group has the same innovative spirit as we have.”

Software solutions ensure smooth workflow

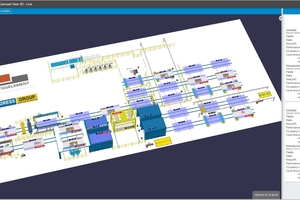

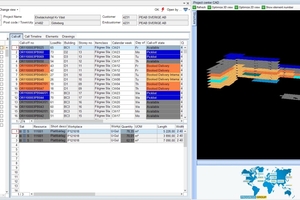

The Ebos software is great for controlling, monitoring and analyzing the complete production process. The entire process can be monitored in detail, providing a better visual overview of where the elements are. Byggelement knows at any moment what is being produced, where the bottlenecks are, and how to reach optimal productivity by providing a digital helicopter view of production. The same is true for the ERP system: Tobias Rönje states that Erpbos from Progress Group is the strongest product on the market. This integrated, cost-effective solution is now used in all plants and provides a single platform for sales to production planning and logistics to invoicing. Erpbos also supports CSRD, which tracks the environmental impact of concrete elements, including carbon calculations and EPDs (Environmental Product Declarations) per element and concrete mix.

Going for a turnkey solution for the entire plant was the right decision for Byggelement also from an investment point of view. Another important reason was the outstanding service and personal connection with Progress Group. According to Carl Rülcker, it ultimately comes down to the people working with each other, communicating from Sweden to Italy and back and solving issues together. For example, the software solutions have not only been implemented in the new factories, but also in the two existing factories. Such complex topics were solved thanks to a continuous, clear communication process.

Progress with Progress Group

“Professionalism, personal relationship, flexibility and willingness to help,” this is how Carl Rülcker describes his experience with Progress Group, adding: “When you do unique projects like this, not everything will work as planned and the relationship is built on how you solve these issues. Progress Group knows how to solve the issues and listens to the customer which has been very much appreciated by the entire Byggelement team.” He goes on to say that Progress Group has an offering that stands out with both machinery and software, which makes the customer experience more seamless. “To summarize, we are very satisfied with this collaboration,” say Carl Rülcker, chairman and CEO of Peab Byggsystem AB, and Tobias Rönje, CEO of Byggelement.

CONTACT

Byggelement AB

Ucklum Factory

Presstorp 106

44494 Ucklum/Sweden

+46 150 48 22 00

Byggelement AB

Hallstahammar Factory

Rallstavägen 76

73492 Hallstahammar/Sweden

+46 150 48 22 00

Ebawe Anlagentechnik GmbH

Dübener Landstraße 58

04838 Eilenburg/Germany

+49 3423 665-0

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159