EPDs demystified: What are they, and what are they used for?

The construction industry is as basic for our lives as are only few others. Living outside closed rooms or traffic on unpaved roads? Hard to imagine in everyday life. But the construction industry is not only significant for people: its influence on the environment is also immense.

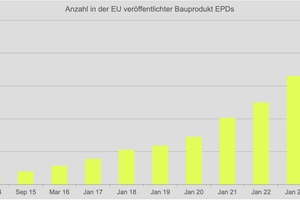

Between 30 and 40 % of worldwide emissions originate from the construction and real-estate industries, and 60 % of raw materials consumption originates from the building sector. Reason enough for lawmakers to take a closer look at these data. In the EU, this is to be achieved by means of Environmental Product Declarations (EPDs). Sounds good at first, but what in fact are EPDs exactly?

Structuring through standardization

EPDs contain relevant environmental data for construction products. Numerical values are represented and calculated by standard procedures to enable analysis of different products in individual categories, based on their impact on the environment. This reliably established data basis enables consumers, companies and politicians to make informed decisions.

Manufacturers can enhance their visibility by especially good environmental performance. EPDs are especially attractive for customers aiming, for example, for certification based on the point-based LEED or BREEAM systems. As of the end of 2024, moreover, the Construction Products Regulation (CPR) will come into force, which will make verified environmental data successively mandatory for all products with the CE mark.

For a long time, establishment of EDPs was a greatly involved process

Standardization of environmental data, however, has its downside. The initial process for establishing an EDP requires many steps and can be tedious. The road to the final document is described in the following:

1. Data collection: In order to calculate target figures in accordance with regulations, the input values must be determined. This is the responsibility of the manufacturer of the material and comprises all steps of the product life cycle – from extraction of the raw materials to disposal. In the sense of accurate calculation – and to avoid overestimations – the following applies: the more thoroughgoing the data collection, the better.

2. Life-cycle assessment: Based on the collected data, an external consulting firm usually prepares a life-cycle assessment (LCA) for the product. It rates the environmental influence of each raw material, as well as every process step. The results of the life-cycle assessment can be used to identify and proactively improve environmental hotspots.

3. Background report and EPD draft: The background report is prepared in addition to the life-cycle assessment for documenting the method used for its preparation as well as the data sources. Based on the background report, the manufacturer and verifier are able to reconstruct in every detail of how the data were collected. A draft of the EDP is developed based on the life-cycle assessment and the background report.

4. Independent verification: Third-party organizations, which must be independent of manufacturers and the creators of the EDPs, are retained for rigorous checking of the EPD draft. Verifiers can request submission of revisions and corrections, which can prolong the process.

5. Program operators: After the final EPD has been verified, it is submitted to a program operator for publication. Program operators register EPDs and publish them in the specified format. Ecoplatform, a non-governmental organization, ensures that calculation methodologies are harmonized and all EDPs published in Europe can be accessed by stakeholders.

Seeing EPDs as opportunity

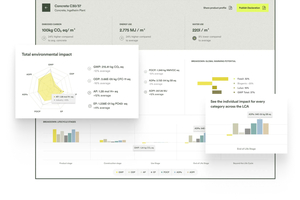

Emidat, a recently established Munich company, saw a market gap for this complex procedure of many months duration. It accordingly developed a tool to automate the creation of verified EPDs by collecting the data directly from the systems of the clients and by preparing LCAs and EDPs in conformity with the standards. The software was recently verified by the program operator EPD Norge, with the result that fully verified EPDs can be issued following a single brief check. Based on this procedure, preparation of LCAs and EDPs can be reduced from months to a few hours.

Supported by such powerful software, some companies now regard the collection of ecologically significant data required for EDP preparation as a promising opportunity. In this way, the environmental impacts of product changes can, for example, be calculated early and taken into consideration in developing products. Manufacturers can, moreover, gain unique characterization and cater to projects that place special importance on green materials.

Industry leaders are convinced that environmental data, together with price and characteristics of a product, will become one of the key decision-making factors for selecting a material. With its scalable solution, Emidat aims to facilitate transparency and to reward manufacturers fair returns for their efforts in sustainability.