ERP solution for a wide range of products

Freedom of design in planning and execution: Architects as well as investors and clients appreciate these aspects in the selection of products. Therefore, the manufacturers‘ response is a wide variety of versions and possible configurations. To prevent that this makes the production process more complicated, the product configurator is a fundamental component of the ERP complete solution developed by Softbauware. It simplifies quotations, production management as well as the initial training of new employees.

Times are changing – while for financial reasons one and the same architectural drawing was used for an entire street of houses, in the past, the clients‘ focus is now on an individually designed house. It plays an important role for planners and investors, how versatile the options are for the design of buildings and structures. Against this backdrop, the requirements on the manufacturing companies are changing as well. They offer an as large variety of product versions as possible in order to meet the current demands of the market and to be able to keep up in the competition with other companies. However, any expansion of the product portfolio makes the production and its processes more complicated. Because a large number of versions and configuration options also means a rising range of potential issues and problems for the manufacturer.

Sophisticated product configurator

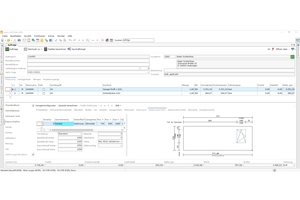

Errors can be avoided, first and foremost, by predictive planning and an excellent product management. To ensure both, the Softbauware software company has conceived an integral ERP solution. This solution interconnects all areas of the company, from purchasing of goods to the production, staff management through to logistics so as to ensure the best possible production processes. An important component of the software – awarded with the title „ERP of the year 2024“ in the category variant-rich manufacturing – is the product configurator. Within the application, items can be differentiated according to different features and characteristics. This includes, among others, the dimensions as well as the color or the number of windows and sockets.

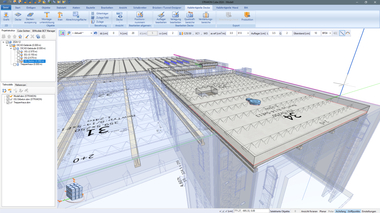

For simplified invoicing, every single characteristic can be priced individually. Stairs, columns, L-shaped elements, or even more complex systems like garages are examples of configuration items in the precast concrete industry. August Lücking GmbH & Co. KG has been using the system with great success for several years now. Recently, it has stand the test in a technically most demanding project once again. A spiral folding staircase made of concrete left the production flawlessly. Richard Lemke, the authorized representative of the company, states: „We are only able to deliver a project that is as complex as a spiral folding stair having this quality thanks to technological support. It represents an outstanding example for the collaboration of digitalization and automation. The technical draftsman creates a 3D model of the staircase. This is used to transfer reinforcement and formwork automatically to the bending machine and the CNC milling machine.“

Central knowledge management

The production processes can be simplified by storing all items and configurations in the ERP system. It can be specified, for instance, what the production is able to achieve and what is not possible – and in consequence, which versions are available at which date. This makes quotations much easier. In addition, background information to each product can be stored in the software as guidelines. In this way, the solution also contributes to the internal knowledge management and new employees in sales can be brought up to speed. Because the accumulated knowledge regarding products, configurations and the production is stored centrally.

The large number of default settings and intersections within the ERP system allows for detailed assessments by means of the product configurator. It is always evident, which products are sold to what extent. This does not only make the process transparent, but it can also be concluded in which direction a product has to develop to meet the challenges of the market as well as the customer requests.

The requirements on software solutions are in a constant state of change. „New products can be outdated or unusable within a few weeks because of changes in the market. In order to prevent this, the product configurator can be dynamically adapted to new conditions at any time. For this purpose, we deliver the system together with the corresponding development environment. Hence, the manufacturers can make modifications themselves,“ explains Andreas Hougardy, Managing Director of Softbauware.

CONTACT

Softbauware GmbH

Raiffeisenstraße 22

63225 Langen/Germany

+49 6103 3727700