Experience from 15 years of repair and rehabilitation using carbon-reinforced concrete

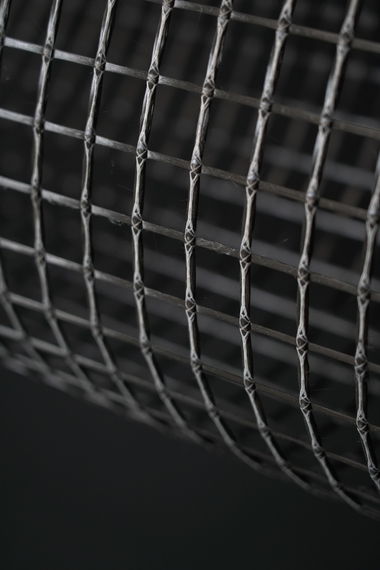

Over the past 15 years, extensive experience has been gained in the repair of concrete structures using carbon-reinforced concrete. This material excels with its outstanding properties, namely its high tensile strength, corrosion resistance, and low weight. These characteristics result in significant advantages over conventional materials such as steel reinforced concrete.

One of carbon’s key applications is to substitute conventional reinforcement. Steel reinforcement is susceptible to corrosion, particularly in moist and aggressive environments. In contrast, carbon does not corrode, which significantly extends the service life of structures while driving down maintenance costs. Carbon-reinforced concrete offers major benefits in this regard, particularly for parking houses, bridges and marine structures.

In addition, carbon-reinforced concrete has a positive effect on crack formation in concrete because its high tensile strength, combined with tight reinforcement spacing, significantly reduces cracking and ensures more uniform crack distribution. This improves the integrity of structures while increasing their durability, especially in heavily frequented areas such as parking garages and transportation infrastructure.

Carbon is successfully used as an anode material in cathodic corrosion protection (CCP). This dual function of reinforcement and corrosion protection results in longer service lives and reduced maintenance requirements. CCP with carbon-reinforced concrete has been implemented primarily in parking garages since these are particularly susceptible to corrosion owing to moisture and the impact of de-icing salt.

Koch Carbon Consulting GmbH has designed and implemented numerous construction projects using carbon-reinforced concrete. In this process, many new ideas have been generated on how carbon-reinforced concrete can be used in further applications to develop innovative and sustainable solutions.

Combining reinforcement substitution, crack reduction, and CCP makes carbon-reinforced concrete a future-proof solution for the sustainable repair and rehabilitation of structures that is associated with significant environmental and economic benefits.