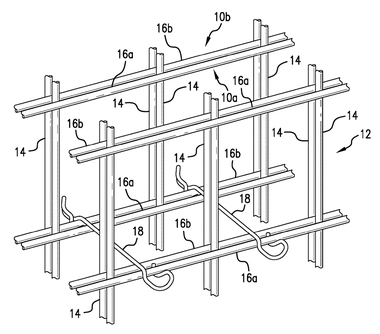

Innovation: conventional reinforcement construction for carbon concrete

The non-metallic reinforcement products currently available on the market are for the most part flat in shape and, as form products, must be custom-made in a complex non-serial process. The innovation involves the production of formed reinforcement from non-metallic reinforcement. With the forming process for non-metallic reinforcement mesh featuring thermo-formable matrix – as developed by the company Johne & Groß GmbH – three-dimensional elements and constructions have been manufactured since 2021 from flat reinforcement products quickly and cost-efficiently. It is possible to produce reinforcement not only from solid reinforcement, but also products adapted to lightweight-concrete construction.

The process chain here is based on conventional processing in steel-reinforcement applications: formed reinforcement products are manufactured from flat reinforcement products and are subsequently delivered to precast plants or cast-in-place construction sites. Integration of non-metallic reinforcement products is therefore directly possible in existing plants and production processes in concrete construction work.

Application areas for the innovation / advantages over steel-reinforced concrete

The non-metallic, flat reinforcement mesh was developed for strengthening, restoring and reinstating existing steel-reinforced concrete structures and has been used since 2014 in flat form within the scope of the CarboRefit Permit Z-31.10-182. As reinforcement mesh from Johne & Groß GmbH, its field of application has been extended for use in existing buildings. The mesh has already been installed for reinstating bridge caps, for example, and can be used for reinforcing bridge piers, columns and joist floors.

First pilot projects in the newbuild sector as well evidence the successful implementation of concrete elements with formed non-metallic reinforcement. Examples are the first transformer station constructed of carbon concrete by the company Betonbau BBD GmbH and the Finnland Pool Edge System from the company Agrob Buchtal. Construction elements that – due to their geometry, require formed reinforcement and are, at the same time, subjected to special exposure – can be appropriately reinforced with formed non-metallic reinforcement. The corrosion resistance of the reinforcement material ensures longer service life of the concrete elements. Furthermore, the thickness of construction elements can in specific cases be reduced, which can result in significant savings of concrete.

Improvements following application of the innovation

The formed non-metallic reinforcement from Johne & Groß GmbH thus plays a role both in the reduction of CO2 emission and of resources consumption in concrete construction. Its use for restoring, reinstating and strengthening can prevent premature demolition of existing steel-reinforced concrete structures, thereby continuing their utilization. In newbuilds, savings in concrete can be achieved in combination with non-metallic reinforcement CO2-reduced alternative binders. Savings are likewise possible in the required concrete volume, since minimum concrete cover for concrete with conventional steel-reinforced-concrete construction as corrosion protection is not required.

The previously considerably limited application of non-metallic reinforcement due to the offer of primarily flat products can be significantly extended by the formed CFK reinforcement from Johne & Groß GmbH.

CONTACT

Johne & Groß GmbH

Kamenzer Str. 18

01936 Schwepnitz/Germany

+49 160 9350 0963