First fully decarbonized cement plant in Germany

The EU Innovation Fund, one of the world‘s largest funding programs for innovative low-carbon technologies, supports Heidelberg Materials with 191 million euros for building up an innovative CCS value chain at the Geseke location. The funding complements the company’s own significant investments. After finalizing the grant agreement, the project officially started on January 01, 2024. Geseke will be the first German cement plant that will be producing net-zero cement and clinker on the basis of CCS (carbon capture and storage), according zo the supplier.

„The successful conclusion of the grant agreement demonstrates the significance of GeZero for the decarbonization of our sector and the confidence the European Commission placed in us,“ states Dr. Nicola Kimm, Chief Sustainability Officer and member of the executive board of Heidelberg Materials. „Only recently, we have introduced our brand evoZero, the world‘s first CCS-based net-zero cement. The product is offered by our Brevik CCS project in Norway at first. As soon as further sequestration projects, such as GeZero go into operation, these plants will also be in the position to supply net-zero cement and clinker to the customers. This will accelerate decarbonization of our industry considerably.“

In this regard, Mona Neubaur, Minister for Economic Affairs, Industry, Climate Action and Energy as well as Deputy Minister-President of the State of North Rhine-Westphalia commented: „With about a third of the nation-wide cement production, North Rhine-Westphalia is a central location of the sector. Therefore, we are very glad that with the first decarbonized cement plant in Geseke in the Soest district a beacon project will be created for a sustainable and climate-neutral future of the cement industry. GeZero shows possible solutions how climate protection can be achieved by new technologies and processes even in energy-intensive industries. This is an important step towards a sustainable cement production and a net-zero industry in North Rhine-Westphalia, Germany and beyond.“

EU Innovation Fund supports GeZero project with €191 million

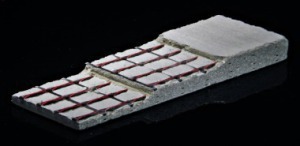

Apart from the construction of the carbon capture facility and a new Oxyfuel kiln, the special approach also comprises a solution for CO2 transport by train, bridging the gap until the required pipeline infrastructure will be available. Around 700,000 tons of carbon dioxide shall be captured per year. Carbon dioxide is carried to the CO2 hub of Wintershall Dea and afterwards stored beneath the North Sea in a safe way. The construction of the facility is scheduled to start in 2026 and commissioning for 2029.

„Together with our partners, we pave the way for CCUS in Germany,“ says Christian Knell, speaker of the management of Heidelberg Materials Germany. „GeZero supplements our global project portfolio by a really unique approach. We are developing a promising, innovative solution for cement plants with landlocked locations and, at the same time, intend to inspire the companies in our industry and other emission-intensive sectors to follow this way.“

The EU Innovation Fund is concentrating on flagship projects in Europe which can lead to significant emission reductions. On the third call for proposals regarding major projects, the European Commission received 239 applications. With 37 of them being selected for funding and a grant agreement has been signed. The ANRAV project of Heidelberg Materials in Bulgaria was already supported by the EU Innovation Fund last year. The project aims at installing the first fully integrated CCUS facility in Eastern Europe featuring a capturing capacity of approx. 800,000 tons of CO2 per year from 2028 onwards.

CONTACT

Heidelberg Materials AG

Berliner Straße 6

69120 Heidelberg/Germany

+49 6221 481-0