Fresh concrete moisture as an essential parameter for the strength development of concrete

“Those who measure, measure crap.” Has this ever happened to you? Individual experiences range from annoying to dangerous. Measurement methods for determining material moisture contribute to describing processes consistently and to mapping them in plant management systems in order to enable end products of consistently high quality. In the field, we are often told that this is what an experienced mixing plant supervisor is also able to do: that may be the case but, in times of a shortage of skilled labor and difficulty in attracting young people to the industry, plant operators are compelled, so to speak, to additionally qualify suitable technology. This serves to ensure that quality is maintained in the future not only in terms of staff but also in structural terms, and to prepare for the transition from one generation to the next.

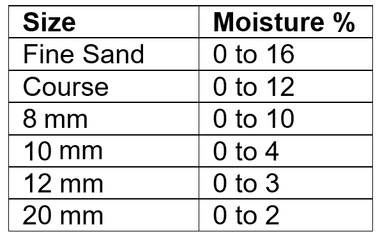

Measurement as such is simple: material moisture can be determined by means of various standard methods or by means of

sophisticated electronic measurement methods. A reliable technology has been developed by Imko. The basic Trime technology has been continually advanced and offers a high-precision measurement solution both in aggregate monitoring and in the mixer. Measurement takes place where the results are important for the process and where there is a representative amount of material flow.

Subsequent determination of the fresh concrete moisture on the construction site is by far the most prominent measuring point. The Sono-WZ is used in this process, which requires mere seconds per single measurement to determine the water-cement ratio and conductivity

of the fresh concrete. The large sample size of an entire bucket also allows for a genuinely representative look into the quality of the product. Measuring conductivity allows additional conclusions to be drawn about the quality of the concrete formulation.

In the next step, the Sono Cure can be used to track strength development in the laboratory or in the mold and, unlike other temperature sensors on the market, can provide an integral status description.

When it’s done this way, measuring is fun: “Measure with pleasure.”