From gray to green: Redesigning a memorial

With an original height of 38 m, the gray-colored bunker in Hamburg’s St. Pauli district is a colossus, a memorial and monument to history, a place for creative people, and one of Hamburg’s landmarks. The building is currently extended by five floors in the shape of a pyramid and will be given a “green cap” in the form of an urban garden. Gray turns green: the sophisticated products from Schöck were in demand to realize this complex design in accordance with state-of-the-art building physics.

Raising the height of the gray-colored concrete giant next to the Millerntor Stadium will be completed in the course of 2022. The stories added to the St. Pauli bunker will further accommodate a multipurpose hall for school sports and cultural events offering space for an audience of up to 2,200, areas for district initiatives, accommodations for scholarship holders and artists, and a memorial and information center dedicated to the victims of the Nazi regime and World War II.

Complex structural design

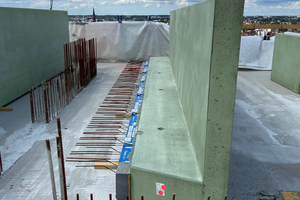

The terraced extension of the former flak bunker with direct connection of the concrete elements and cantilevers of different lengths was a conceptual challenge even for the experienced building experts of the Phase 10 design and engineering firm headquartered in the Saxon town of Freiberg. To connect the new green-colored parapet elements to the newly built floor slabs, the architects and engineers relied on the Schöck Isokorb, a load-bearing thermal insulation element for cantilevered structural components. They did so because realizing this exceptional building project required not only a variety of types but also first-class, reliable product quality with high load-bearing capacity – attributes that the Schöck Isokorb, having been technically approved, fulfills on all counts. A total of 20 different types from the Isokorb product range were used on the flak bunker, with Schöck experts advising the designers regarding their selection.

The parapet elements of green-colored concrete were prefabricated and the different types of Isokorb directly installed at the precast plant. The thermally separated precast elements could then be connected to the new floor slabs in a time-efficient process on the construction site. Production of the precast elements and processing of the structural members on site went smoothly despite the large variety of types and products. This was due to the good processing instructions provided by Schöck, which were appreciated by Ingenieurbau George Bähr GmbH, the company in charge of shell construction.

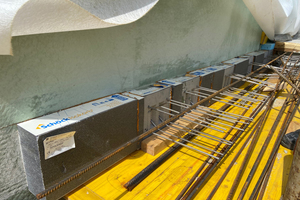

Schöck Stacon for reliable load transfer in expansion joints

The Schöck Stacon provided the engineers with a simple and reliable solution for the non-restrained transfer of shear forces in expansion joints. The shear dowel connects joints to adjacent structural components without requiring additional structures. It was thus possible to dispense with conventional measures such as support brackets, friction bearings or Gerber joints. Several hundred shear dowels with fire protection sleeves were installed in the joints of the concrete façade elements of the “green bunker” to connect them to each other and to evenly absorb potential settlements. Redesigning the bunker as a cultural and recreational facility also required intelligent structural solutions for the interior in order to create a harmonious combination of the different types of use.

Impact sound insulation with Schöck Tronsole

The background noises created by the expected visitor numbers therefore needed to be reduced to the greatest possible extent. The multipurpose hall offers space for an audience of up to 2,200, after all, and this amounts to a lot of steps and, consequently, a lot of noise.

Silence in the stairwell of the bunker is ensured by the Schöck Tronsole sound insulation system, which acoustically isolates the staircases in the interior stairwells. The system comprises multiple Tronsole types that offer different combination options and therefore incorporate all of the connections present in the stairwell – even the joints are kept free of noise pollution, and therefore of sound bridges, due to the use of the Tronsole system. The precisely matched variants of the impact sound insulation element – the so-called blue line that surrounds the staircase after proper installation – reduce noise and ensure reliable sound insulation. Sound insulation class III as specified by VDI 4100 for staircases becomes standard with the Tronsole system.

CONTACT

Schöck Bauteile GmbH

Vimbucher Str. 2

76543 Baden-Baden/Germany

+49 7223 967-0