Influence of hydration and water content on the brightness of hardened cement paste

The coloration of concrete surfaces is a primary architectural feature. This paper investigates and quantitatively evaluates the influences of hydration and water content on the resulting color of hardened cement paste by meansof calorimetric parameters.

Modern concrete construction elements are subject not only to wide-ranging requirements but must frequently satisfy demanding aesthetic expectations such as a defined color. In this context, the color of concrete surfaces is a primary architectural feature. On concrete elements manufactured with a smooth, non-absorbent form fabric, a thin layer of cement paste or hardened paste forms on the surface of the building component. This is essential for the visual impression, and especially for the coloration and/or brightness of the construction element.

On the basis of colorimetric parameters, this paper investigates and quantitatively evaluates the influences of hydration and water content on the resulting color of hardened cement paste. In this way it is possible to integrate additional features of the initial constituents for consideration of the aesthetic properties of high-quality architectural concrete elements in planning and in concrete development.

Introduction

Apart from technical requirements such as loadbearing capacity and durability, architectural concrete elements must especially satisfy expectations regarding the aesthetics of the concrete surface. Surface characteristics such as the texture of the surface, the shape, the arrangement and the design of joints and particularly the color are essential for the architectural and aesthetic impact of the construction element. A color as perfect and uniform as possible is expected, especially for precast elements made of architectural concrete (cf. [1]) – the realization of which, however, is a challenge in practice. Accordingly, color is a primary feature for the architectural impact of a construction element or building, especially when architectural concrete is used.

A great number of factors influence the final visual appearance of concrete surfaces in the implementation phase, as well as in the subsequent utilization phase. These factors include the interactions between release agent, form fabric and concrete as well as the weather conditions following striking [2, 3]. During the planning phase, the choice of raw materials and the determination of concrete properties play a decisive role for the resulting color of the concrete surface [4, 5]. The color of the cement, for example, can vary already due to its composition or also due to the mining region of the raw materials and to the production methods used [6].

Although – as early as in the planning phase – the choice of cement type and the additions to concrete predetermine the final visual appearance of the color of an architectural concrete surface, these factors do not determine its final appearance. [7, 8]. The final color and the brightness of hydrated cement are influenced, apart from the cement and/or fines content, to a great extent by the phase composition of the cement clinker and here, again, by the proportional content of iron-rich melting phases (e.g., tetracalcium aluminoferrite, C4AF) in the clinker [6]. Moreover, the ambient conditions (temperature, curing etc.) during hydration of the concrete are also decisive for the coloring of concrete surfaces [8]. In addition to the composition of the cement and the ambient conditions, the water content and the w/c ratio are additional decisive parameters for influencing color and/or brightness. The microstructure near the surface depends directly on the water content and/or w/c ratio, which also influences the color and/or brightness. The rougher and more open-pored the concrete surface, the more light is refracted in diffused manner and leads to modified remission behavior [9].

The physical fundamentals for these relationships are described in [10]. Based on these aspects, a concrete surface with a high w/c ratio and open-pored structure appears brighter than a concrete surface with a low w/c ratio and dense structure [4].

The preference of many planners and clients continues to lie, in modern architectural concrete, on smooth concrete surfaces with a uniformly light color. Accordingly, the present paper describes the influences of hydration and water content on the resulting color of hardened cement paste, quantitatively evaluated with colorimetric parameters. Here one can observe a great variety of normative types of cement, with varying composition (especially clinker content, the main constituents of cement and cement types as well as additions). The emphasis of the present paper lies on the laboratory investigations of small samples. Applicability, however, is definitely possible to concrete surfaces manufactured with smooth, non-absorbent form fabric. The following section begins with a brief overview of the fundamentals of colorimetry and the resulting consequences for color measurement.

Fundamentals of colorimetry

Color is not a physical or primary material property but is a human sensory perception. For perception of color, light is required so that the reflective properties of the surface of an object trigger a color stimulus in the observer. Depending on the wavelength range, light is allocated a specific color, whereas only the wavelength range of 380 nm to 729 nm is visible to humans [11]. Dimensional relationships between individual colors can be expressed by colorimetry. In general, a differentiation is made between achromatic and chromatic colors. Achromatic colors can be described only by their brightness and are therefore one-dimensional. For the description of chromatic colors, in contrast, three non-correlated factors are essential. For technical recording of colors and/or color information, measuring instruments as well as special measurement systems are required because – as already mentioned – physical measurands are not involved.

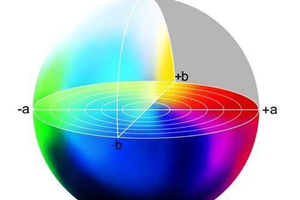

The so-called standard spectral value functions serve as the point of departure for colorimetry. With the aid of colorimetry, colors can accordingly be objectively measured and explicitly expressed by numbers [11]. The numerical description of colors takes place with colorimetric values in various color spaces. In the course of time, the various color spaces are defined of which the CIE-L*a*b* color space has been accepted also in building construction. The CIE-L*a*b* color space was introduced in 1976 by CEN and is defined in DIN 6174 [12] and DIN EN ISO 11664-4 [13]. The colors perceived by humans are transferred into the CIE-L*a*b* color space in a geometric presentation and, in the process, are largely represented nearly equal in length. This technique achieves a demonstrably high accordance between the perceived color distance – i.e., the difference between two colors – and its geometric representation in the color space. The color space is developed in cylindrical shape as a three-dimensional coordinate system (cf. Fig. 1) and is spanned by the brightness (L* value) and the colorimetric values (a* and b* values). Brightness is expressed by the dimensionless parameter L* and can assume values between L* = 0 (black) and L* = 100 (white). The calorimetric value a* describes the red/green axes, wherein a green coloring denotes a negative value and a red coloring, a positive value. The third parameter, b*, corresponds in the positive range to a yellow coloring and, in the negative value range, to a blue coloring – which, accordingly, defines the blue-yellow axis.

Method of investigation

For a systematic investigation of the influence of hydration and water content on the resulting color of the hardened cement paste, cement pastes of various cement types as well as varying w/c ratio were manufactured. The focus of these investigations was on pure cement pastes, since the resulting color of smooth-formed concrete surfaces primarily depends on the color of the binding agent and its technical concrete properties [5].

Within the scope of the present investigations, cement pastes from various cement types with varying proportions of principal constituents (cf. Table 1) were manufactured with the respective water-cement ratios w/c = 0.30, 0.40 and 0.60 and were sealed and stored for 28 days at 20 °C and 65 % rel. hum. To ensure comparability between the measured value of unhydrated, pulverized cement and the hydrated hardened cement paste, the hardened cement paste was ground to a fineness comparable to the initial cement before determining the colorimetric parameters. For this purpose, the cement paste was first dried for 48 hours at 40 °C in a heating cabinet and subsequently ground in a vibratory disk mill.

The calorimetric parameters were determined by an imaging spectral photometer (MetaVueTM VS3200, X-Rite) and in the CIE-L*a*b* color space, according to DIN 6174 [12] and DIN EN ISO 11664-4 [13]. For this purpose, the samples were filled into a sample mount and the surface was smoothed. The measured area was in each case 113 mm² and three each different samples were measured and the respective mean value determined.

Color of initial constituents in unhydrated state

Fig. 2 shows the various types of cement as well as the various additions in the unhydrated state. It is visually obvious that there is a marked difference in color among the individual cement types. Among the individual cement types and the types of additions, a marked difference in color can also be visually perceived. Depending on the proportional content of the principal non-clinker constituents used, the cement types exhibit a respectively different color. For example, a very bright color shade is perceptible for cement CEM III/B – owing to the high content of granulated blast-furnace slag – compared to the cement CEM I with high clinker content.

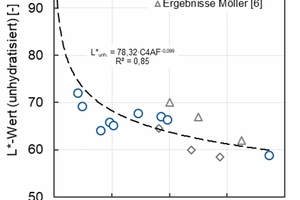

The ferrous clinker phase C4AF is an essential constituent for the coloring of cement [6]. The pure-white coloring of white cements can therefore be explained by the fact that a clinker phase is nearly completely absent in these cement types. In contrast, the grayish coloring of typical cement types results primarily from the blackish proportional contents of industrial C4AF and the white constituents of the siliceous and aluminate clinker phases [6]. The intensity and the brightness of the resulting color depends here on the absolute quantity of the coloring clinker phases, as well as on their composition. Fig. 6 shows the relationship between the L* value of unhydrated cement and the content of C4AF. Clearly obvious here are the very high L* values (nearly white) of white cement with a very low content of C4AF. With increasing C4AF content, a potential decrease of brightness and/or of the L* value is apparent here.

Colorimetric parameters – influence of hydration

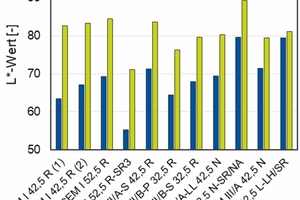

During hydration, hardened cement paste forms phases such as calcium silicate hydrate (C-S-H) and calcium hydroxide CH, which are formed from cement clinker and other principal reactive constituents of cement. Owing to chemical conversion, these phases demonstrate various color properties. Fig. 4 shows a comparison of brightness of various cement types in the unhydrated state, as well as the resulting ground cement pastes in a hydrated state with a w/c ratio of 0.40. The calorimetric parameters were then determined on powders of comparable fineness. The higher L* value is clearly apparent in each case in the hydrated state, with accordingly increasing brightness, independent of the cement type. It is noticeable, however, that the brightening is clearly more pronounced in the pure Portland cements CEM I. With increasing content of additions in the cement (cf. Table 1), a decreasing brightening effect can be observed due to hydration. For evaluation of this brightening due to hydration, the so-called thinning effect α was calculated according to equation 1.

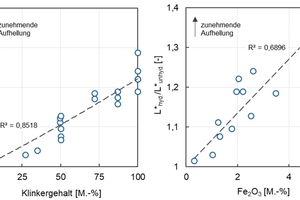

In this formula, describes the brightness (L* value) of the cement in the hydrated state and the brightness (L* value) of the cement in the unhydrated state. Fig. 5 additionally shows the calculated thinning effect α of the investigated cement types as a function of the clinker content of the cement type. For the sake of simplification, the respective normative mean content of additions in the cement was assumed here (cf. Table 1). A clear dependence is here apparent between the thinning effect and the clinker content of the cement: i.e., the thinning effect decreases nearly linearly as the clinker content decreases. Since the cement pastes were made up with a constant w/c ratio of 0.4, the decreasing brightening following hydration with a low clinker content must especially be attributed to stronger “thinning” of the coloring Fe2O3 content around the chemically bound water content (cf. [6]). Fig. 5 clarifies the relationship between thinning effect α and the coloring Fe2O3 content of the cement. The higher the Fe2O3 content in the cement, the more pronounced the brightening due to hydration.

Colorimetric parameters – influence of water content and/or w/c ratio

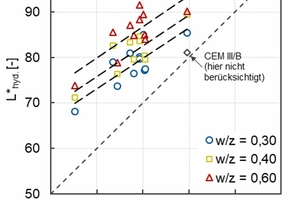

In addition to the cement type and/or the composition of the binding agent, the w/c ratio is a further fundamental influencing factor for the color and the brightness of the hardened cement paste. Fig. 6 shows the colorimetric parameters (L* value) of various cement types in the unhydrated and hydrated states. The previously described brightening effect (thinning effect) due to hydration is clearly apparent.

It is furthermore clearly evident that brightening due to hydration increases with increasing w/c ratio. The color of the hardened cement paste becomes brighter as water content increases. The formation of the structure is directly dependent on the w/c ratio: the greater the ratio, the more open-pored the structure. Open-pored structures generate an increased diffuse reaction, leading to changed remission behavior and brighter visual appearance.

Summary

The present paper examines and, by means of colorimetric parameters, quantitatively describes the influences of hydration and water content on the resulting color of hardened cement paste. The findings of the investigation reveal that the resulting color of hydrated hardened cement paste depends essentially on the Fe2O3 content of the cement used. The greater the Fe2O3 content of the cement, the more pronounced the brightening of the color due to hydration. The same applies equally to the water content and/or the w/c ratio: the greater the water content and/or the w/c ratio, the more pronounced the brightening of the color due to hydration.

In summary, it may be concluded that concrete surfaces, depending on the initial constituents used, as well as on the technological parameters of the concrete, can exhibit noticeably varying color properties. The findings presented here can, for example, be integrated in further characteristics (colorimetric parameters or composition of initial constituents, etc.). The choice of initial constituents and the adjustment of technological properties of concrete can accordingly be specifically configured for planning the respective requirements regarding color.

REFERENCES/LITERATURE