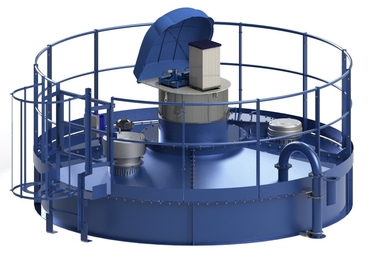

Inn. Shield Lite silo protection system

Shield Lite, according to the manufacturer, is a unique silo protection system for powder silos. During pneumatic filling of storage silos by tank trucks, there is always the danger of overpressure incidents: e.g., when safety equipment does not properly function, or is manipulated, or when human errors lead to failure. These safety-relevant problems are also the order of the day in concrete plants because the drivers of tank trucks and facility personnel are under time pressure, maintenance intervals are often omitted or technical problems are overlooked. Overpressure incidents can cause serious injuries to personnel and even death. They have environmental impact due to material leaks and can lead to major damage of facilities. Shield Lite is fail-safe: when problems arise or human errors occur, pneumatic filling cannot take place or is automatically interrupted.

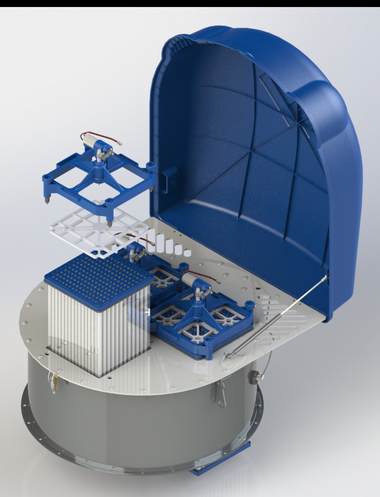

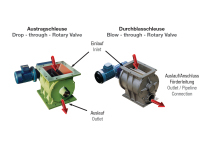

Shield Lite is a complete solution. It consists of the following fail-safe systems: pressure-relief valves, pressure sensors, filling-level sensors, inlet-stop valves and the ground-level-test control unit at the filling point. The ground-level test subjects every Shield Lite component to a test every six seconds, and pneumatic filling of the storage silo can begin only when the test has been successful. Every filling operation is therefore safe and problems that may arise due to human error, manipulation or technical defect during filling are prevented or recorded. Damage caused by overpressure incidents is prevented, and the danger to persons, the environment and the facility eliminated. Shield Lite is the only complete system on the market that offers this safety standard.

Shield Lite is therefore absolutely relevant for safety in concrete plants and offers, at the same time, additional improvements in the process: because the time and effort involved in maintenance and maintenance costs for storage silos, as well as deployment of personnel and working at heights can be significantly reduced.

CONTACT

ENVEA GmbH

Gutedelstraße 31

79418 Schliengen/Germany

+49 179 341 83 96

info@envea.global

www.de.envea.global/