Improving silo safety, reducing emissions

To achieve the Agenda 2030 sustainability goals, plant operators in all industries must reduce energy costs, lower dust and carbon emissions, mitigate noise, and improve the safety of plants and for operating staff. In this respect, it is the construction materials industry that has come under increased public scrutiny owing to its energy-intensive production of raw materials. We demonstrate how the individual goals can be achieved by installing state-of-the-art plant components.

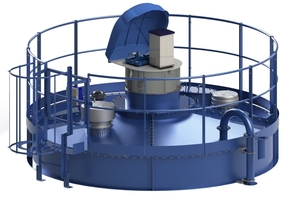

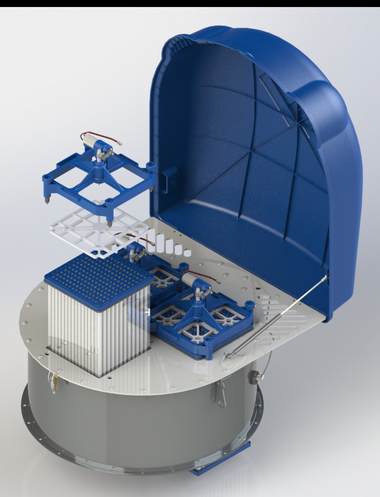

For this purpose, we take a closer look at a silo system and discuss the individual components of silo monitoring, namely level and pressure monitoring, which help ensure safety during the pneumatic filling process of the silo while lowering compressed air consumption of the entire system and reducing energy consumption. Using the example of the Silotop polyTube venting filter developed by Wamgroup, we explain how the use of state-of-the-art nanofiber filter elements, which separate even the smallest particles from the air escaping during the filling process, can reduce the residual dust load and thus lower dust emissions. The Silotop polyTube’s innovative cleaning system employs a mechanical pulse to clean the dust-laden filter elements in a much more energy-efficient manner than conventional compressed air systems. Eliminating the compressed air line to the silo roof also prevents leaks and critical operating conditions caused by fluctuating or low ambient temperature levels.

Combined with the other components, this setup makes the silo system safer and more sustainable while enabling operators to reduce energy consumption and operating costs even further.