Interview: “Our vision: Removing 1 million tons of CO2 permanently by 2030”

As already announced several times, dear readers, we are launching our new „GREEN CHALLENGE“ section with this issue of BFT 12/2023. It kicks off with the following interview with Dr. Johannes Tiefenthaler, CEO of neustark - a Swiss ScaleUp that has developed a solution for the permanent storage of biogenic CO₂ in mineral waste streams such as demolition concrete. BFT editor-in-chief Silvio Schade recently visited Dr. Tiefenthaler in Zurich and we will be presenting neustark in detail in BFT 1/2024.

According to the IPCC, limiting global warming to 1.5°C requires net-zero emissions to be reached by the year 2050. This goal can only be achieved if we remove carbon dioxide from the air in addition to reducing emissions significantly. For this purpose, we must quickly implement carbon removal solutions to the scale of billions of tons. Neustark is a leader in the fast-growing field of carbon removal (CDR) and has developed a solution for the permanent storage of biogenic CO2 in mineral waste streams such as demolition concrete. The first plants have been commissioned in Switzerland and Europe, storing several tons of CO2 every day even at this early stage. This process removes the carbon dioxide permanently. Neustark is currently working to increase its business activities and impact worldwide – on the route to their ambition of permanently removing 1 million tons of CO2 in 2030 and beyond.

BFT International: Mr. Tiefenthaler, the decarbonization of the construction industry, and more specifically of the concrete industry, is one of the most important and most pressing issues of our time. How exactly can your innovative technology for storing CO2 in concrete help with this?

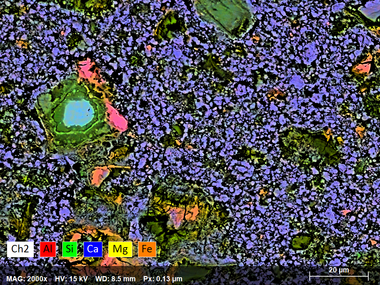

J. Tiefenthaler: About one billion tons of demolition concrete are generated on a worldwide scale every year, and we put some of this material to beneficial use. We bring biogenic carbon dioxide into contact with the demolition concrete, which triggers a chemical reaction: CO2 binds to the surface of the demolition concrete and turns into limestone. It is thus permanently stored. We are currently able to permanently store about 10 kg per ton of demolition concrete, and we are working on increasing this ratio to 60 kg per ton.

BFT International: As a young scale-up business employing about 55 people, you have already attracted a lot of positive attention. You have commissioned several plants in Switzerland within a brief period, and additional facilities are currently under construction in the DACH (Germany, Austria, Switzerland) region. Can you tell us more about it?

J. Tiefenthaler: At the end of September, we put our first facility in the EU into service in Berlin in cooperation with Heim Group. This marks the start of our expansion in Germany. In addition, about 15 other projects are under construction in the DACH region and France. We currently operate 12 plants in total, eleven in Switzerland and one in Germany, with a cumulative storage capacity of 5,000 tons of CO2 per year.

BFT International: I was also personally delighted to hear the news that Holcim, one of the big players in cement and concrete production, has committed to introducing neustark’s carbon storage technology at its recycling plants worldwide. How did you achieve this success and how many tons of CO2 do you expect to be stored?

J. Tiefenthaler: This strategic cooperation agreement was the result of about 18 months of successful collaboration. We carried out several projects with Holcim and have also provided them with a mobile storage facility since May 2023. Over the months, both parties became interested in working together not only on a project-by-project basis, but also on a more strategic level. We aim to permanently remove one million tons of CO2 by 2030. Our strategic partnership with Holcim is a key part of our megaton roadmap.

BFT International: In your opinion, for how long can CO2 be stored in concrete?

J. Tiefenthaler: Even if the concrete in which the CO2 is stored is demolished repeatedly, the CO2 will not be released back into the atmosphere. The mineralization method on which neustark’s process is based is one of the few technologies that guarantee permanent CO2 removal.

BFT International: Is the granular carbon-enriched concrete intended to be some kind of storage material, or can it be reused in some form, which would be a much better alternative in our view?

J. Tiefenthaler: The carbonated granular concrete can be used in road construction or for producing recycled-aggregate concrete. The latter is already quite common in Switzerland, but not yet so widespread in Germany. The quality of the enriched concrete is in no way inferior to that of conventional concrete; it can be used in building construction and civil engineering without causing any problems. Depending on the concrete producer’s mix design, its compressive strength can be even higher, and cement can be saved.

BFT International: Mr. Tiefenthaler, many thanks for the conversation und much success furthermore!