Joint project “Printing efficiently and economically”

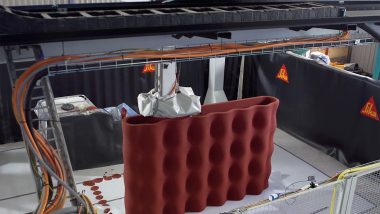

KBH - the think tank - is coming up with a special innovation just in time for bauma to provide manufacturers of concrete products with new ideas for diversification. Printing – efficiently and economically – a joint project with the companies Rhein-Chemotechnik GmbH and Zschimmer & Schwarz GmbH.

Printing of concrete slabs has been a topic in our industry longer time. However, creativity was limited to the extent that our industry‘s goal of realistically imitating natural stone was only achieved to a limited extent. In addition, existing plant designs require considerable capital - not only for machinery and equipment, but also in terms of space requirements and energy costs.

With regard to sustainability, KBH decided to develop an economical system that allows access to a wide range of plant technology available. So far, mainly concrete products produced on slab presses have served as print blanks. However, a large number of vibratory presses are available worldwide, and their operators are constantly seeking for special products allowing to set them apart from the competition.

Suitable for new and existing plants

So, it made sense for KBH to develop a system that would allow blanks to be printed coming from the vibro presses (board machines). “Following the principles of efficiency, economy and sustainability, we have turned to the wet side of a concrete paver plant and developed a printing system that can be installed there – in existing plants as well as in new plants of course”, states Alwin Bennmann, Sales Director KBH. „At bauma sample stones will be on display. We are happy to demonstrate them to visitors.”

The product arrangement according to the mold pattern remains unaffected. Subsequently, the production board is transported with the usual plant components into the curing chamber system for curing. The hydration process binds pigments deep into the concrete matrix to produce a resilient product during curing. After the curing process, the printed concrete products can be processed further as usual, using existing plant technology.

Together with the companies Rhein-Chemotechnik and Zschimmer & Schwarz, KBH has succeeded in creating a new type of concrete product using existing paver plant production technology economically, efficiently and sustainably. Basically, there are no limits to creativity anymore. High level of competitive pressure can be eased and diversification is possible.

Text: Alwin Bennmann